By Tom Matthews

Your home-improvement project is only as strong as the fasteners that hold it together. From nails and screws to innovative metal hardware, here’s a look at some common solutions as well as some of the latest developments in those unsung heroes of house construction.

Coated Fasteners

Today’s exterior fasteners are coated to prevent rust, and some coatings are colored to blend with surrounding materials.

When it comes to nails, exterior-grade galvanized nails are made of steel and coated with zinc. Although galvanize means “to coat iron or steel with rust-resistant zinc,” the amount of zinc on the nail and its method of application make a significant difference in how well the nail will resist rust. Nails that are certified “hot-dipped galvanized” have the critical alloy layers that ensure long-time corrosion-resistance. With hot-dipped nails, the nails are actually immersed in molten zinc.

Maze StormGuard nails are each dipped twice in zinc for a thick uniform coating. Other methods of galvanizing are shown by lab tests to leave nails with a non-uniform coating, a very thin coating, or a coating which frequently chips when hammered.

Tool Tip: Milled-face hammers aren’t recommended for driving galvanized nails because the abrasive surface may damage the zinc-coating on the nail head and reduce its corrosion resistance. Smooth-face hammers are recommended.

Nails can also be pre-finished with a factory color to blend with painted surfaces. Colored nails save time by eliminating the labor-intensive job of touching up nail heads.

Screws are also available with a variety of coatings. GRK Fasteners’ Kameleon Composite Deck Screws work with composite boards and treated lumber and are colored to match today’s most popular decking tones, including Redwood, Brown, Grey, Sand and Tan. The Climatek coating resists corrosion, and the screws have unique fiber-trapping rings that eliminate the common mushrooming effect in composite material.

With white being such a popular color choice for trim inside and outside the home, Screw Products’ new White Head Trim Screw is a multipurpose exterior/interior fastener for a wide range of projects. These fasteners can be used with ACQ and CCA pressure-treated lumber thanks to a proprietary coating designed to protect against corrosion. They’re ideal for materials with a white finish such as fascia, fencing, siding, trim and more.

Adapting to the same color trend, GRK Fasteners offers new White Cabinet Screws for new and remodeled kitchens. The screws have a durable white coating that blends with white cabinets, allowing them to hide in plain sight. They can also be used for other interior applications such as closet and shelving systems.

Stainless Fasteners

In certain severe conditions, stainless steel fasteners are preferable to coated fasteners. These highly corrosive conditions include marine environments (within 5 mi. of the seacoast), as well as cedar and redwood products (siding and decking) where the wood is left natural or treated with a clear wood finish.

For example, SureDrive USA offers Seamaster Stainless Steel Decking Screws with both flat-head and trim-head designs in either square-drive or star-drive. The Seamasters have self-drilling points and self-countersinking nibs, and resist corrosion despite salt-water exposure on docks, decks, boardwalks and boathouses.

Split-free Fastening

SplitStop High Performance Screws from Titan Metal Werks eliminate splits and the need to pre-drill wood, even in dense hardwoods like ipe. The patented thread and tip design also diminishes drive-torque, resulting in less screw breakage, reduced user fatigue and longer cordless-drill battery life.

Similar split-free design features in the company’s Titan III decking screws prevent mushrooming in dense composite or capped-stock-cellular deck boards. SplitStop TIII screws are available in three sizes and five colors plus stainless.

Hammer-Drive Anchor

Ever used a hammer-drive anchor? Also called “drive nail anchors” and “metal hit anchors,” these fasteners are made of sleeved expansion nails designed for tamper-resistant use in concrete, stone, solid brick and block. To use, first predrill a hole using a hammer-drill to the manufacturer’s recommended diameter and depth for fastener size and substrate. Remove the debris with a pipe cleaner, compressed air or vacuum. Insert the anchor through the fixture and into the hole until the flange contacts the fixture. Hammer the nail until the head is flush with the flange of the anchor. The nail creates an expansion of the anchor for a firm hold in the concrete, brick or block.

Deck Hardware

Methods of deck construction evolve over time to adapt to changing building codes. The new changes in technique are meant to ensure a safer deck, and some of the latest requirements relate to the metal hardware fastened to the deck to strengthen its framing connections.

A deck’s ledger connection is the focus of the latest code updates because it’s the leading contributing factor in most deck collapses.

Simpson Strong-Tie offers a deck tension-tie for attaching a deck to a home that meets the latest code standards for securing the ledger. The DTT1Z deck tension-tie fastens from outside the house, allowing the four required 750-lb. lateral connectors to be fastened to structural framing members in the house. The DTT1Z screws to the narrow or wide face of a single 2x joist. Then, a long hex screw with an integral washer attaches the tension-tie to the supporting structure with a minimum of 3 inches of penetration.

A deck’s handrail system is another focal point for making stronger connections.

To construct a sturdy code-compliant deck handrail, DeckLok offers the Advanced Lateral Anchor System. This patented metal anchor adds a bolted attachment at critical structural locations such as the handrail post-to-framing connection. Other deck-fastening techniques rely on resistance to “pullout” force, like using a nail to hold a crowbar. The DeckLok Advanced Lateral Anchor System redirects the force of the load from “pullout” to a connection in “shear” at the deck’s floor joist. The system recently received an updated ESR-2114 evaluation from ICC Evaluation Service (ICC-ES) verifying the bracket’s continued code compliance.

Side Note 1

Which Nail for Which Application

Smooth shank nails are easy to drive but don’t offer much holding power. Choose the best for the job at hand to ensure a firm, long-lasting connection.

Spiral Shank—Maze Nails mill designed and produced the world’s first spiral shank nails, which have a spiral thread that causes them to turn when they are driven. Similar to wood screws, they form their own thread in the wood fibers for extra holding power. They are specifically designed for use with hardwoods and dense materials. Flooring, siding, decking, pallets and truss rafters are typical applications for spiral shank nails.

Ring Shank—Independent Nail, A Div. of W.H. Maze Company, developed an annular (or ring) thread on their nails to provide even better holding power in many applications. The threads on ring shank nails separate the wood fibers, which then lock back into the rings and resist removal. Ring shank nails are widely used in plywood, underlayment, decking, siding and roofing applications.

Fluted Shank—A third type of threading, typical on masonry nails, is a fluted shank. This thread style gives nails excellent holding power in concrete block and masonry applications. The horizontal threads cut the masonry to minimize cracking and provide excellent holding power. Source: Maze Nails, www.mazenails.com

Side Note 2

Penny-Inch Nail Equivalents

2d = 1″

3d = 1-1/4″

4d = 1-1/2″

5d = 1-3/4″

6d = 2″

7d = 2-1/4″

8d = 2-1/2″

9d = 2-3/4″

10d = 3″

12d = 3-1/4″

16d = 3-1/2″

20d = 4″

30d = 4-1/2″

40d = 5″

50d = 5-1/2″

60d = 6″

70d = 7″

80d = 8″

Side Note 3

Heavy-Duty Toggle Bolts

To securely fasten a heavy item to a wall or ceiling, you need a toggle bolt. Toggler Anchor Systems offers the heavy-duty 1/4-in. Snaptoggle BB, which holds up to twice more than wing-type toggle bolts that fold in half when inserted in the wall. The Snaptoggle is quick and easy to install, and uses a single-piece zinc-plated steel anchor bracket to hold up to 1,080 lbs. in concrete block and up to 265 lbs. in 1/2-in. drywall.

Here’s how to use:

Drill 1/2-in. diameter pilot hole.

Fold steel bracket alongside plastic straps and insert through the hole.

Pull straps toward you so bracket rests flush behind wall.

Slide the plastic cap along the straps until its flange is flush against wall.

Bend the straps to the side to snap them off.

Place the fixture (represented by washer) over the flange. Drive 1/4-in. bolt through fixture and tighten until flush.

The bolt pulls the bracket flush and tight against the back of the wall.

Side Note 4

Mount a Screw in a Hollow Door

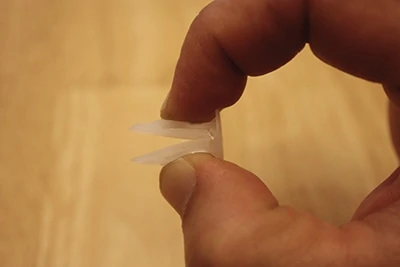

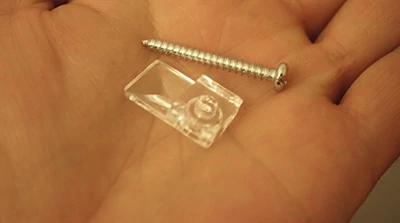

Since there’s not much solid wood in a hollow-core interior door, screws will usually tear out of the door as soon as any weight is applied to them. This complicates mounting items such as pictures, mirrors, hooks, etc. to the door. To mount anything into a hollow door requires special Hollow Door Anchors. These plastic anchors fold flat to fit inside a pilot hole drilled into the door.

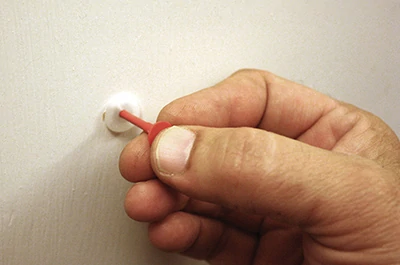

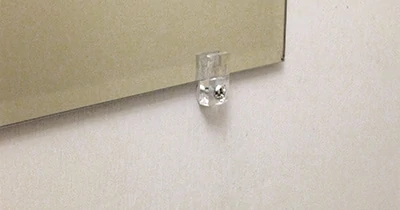

Once inserted, a small key is used to open the anchor, which spreads out interior brackets to clamp the collar of the anchor against the door face, like a toggle-bolt. The screw is then driven into the anchor until tight.

1. Screw, hollow door anchor (white) and key (red)

2. Drill pilot hole.

3. Fold door anchor in half.

4. Insert anchor into hole up to collar.

5. Insert key into anchor to spread open toggle brackets inside door.

6. Insert the screw into to the anchor for a secure hold. In this case, I was screwing a mirror clip to the door.

7. Tighten the screw securely against the collar of the anchor.

8. Repeat procedure for all screws required for your project.