The old boat dock had seen better days. Last winter’s heavy rains had caused the water at Logan Martin Lake in Alabama to rise to abnormal levels. As the water rose, so did the dock, all the way above the tops of the dock piles. A monster storm shifted the dock over the top of one of the posts, where it snagged beneath the corner of the docks’ rim joist. Then, when the water receded, the corner of the dock was stuck on the end of the pile so the structure couldn’t float down evenly with the water. Three corners went down with the water, but one corner didn’t, and the heavy weight of the lumber caused the entire dock to deform into a potato-chip shape that destroyed its construction. The old deck had to go, and the EHT crew built a new one. Here’s how our staff teamed up for weekend project that gave us a new place to kick back, relax and drop a fishing line in the water.

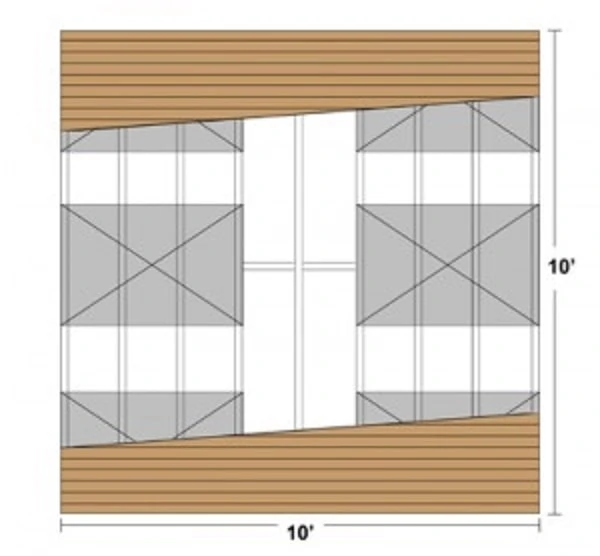

Shown here is the basic plan for the swimming dock. Figure not drawn to scale.

Must-Have Materials

Our plans were for a 10-by-10-foot dock to serve primarily as a swim platform throughout summer until the old boat dock could be demolished and rebuilt. A dock is much like a deck, but it floats, and the state’s lake authority regulates the design and material used to build any structure on the water. In years past, large Styrofoam pontoons could be used as flotation, but the regulations for Alabama waterway structures now requires the flotation devices to be completely encapsulated to prevent artificial debris from littering up the natural beauty of the state’s lakes.

The owner of the lake property ordered a flotation kit online that consisted of six dock floats. These 12-inch thick 2-by-4-foot floats are each foam-filled with expanded polystyrene but have a seamlessly molded outer shell made of extra strong polyethylene, containing ultraviolet inhibitors. This hard shell helps prevent damage from the sun,water, oil, gas and marine organisms, and satisfies the state’s requirements for flotation materials.

A dock must also withstand the rigors of Mother Nature, and she throws a lot at a wooden structure that floats on water. Normal deck framing techniques aren’t intended to contend with the stresses that come from changing pool levels or choppy water. Decks are supposed to remain still, but docks must be built strong enough to shoulder all the extra stress. Whereas as a dock’s building components are much like a deck—floor joists, rim joists and deck boards—the “connective tissue” that binds them is heavy-duty stuff.

Instead of nails, screws or joist hangers, the joints between joists are all connected with galvanized or stainless steel hardware consisting of thick metal plates, 1/2-inch through-bolts, nuts and washers.

The type of framing and decking material is also an important consideration. For this dock, we used Ecolife Stabilized Weather-Resistant Wood manufactured by Viance (www.treatedwood.com). Ecolife is top-of-the-line treated lumber that is protected with a non-metallic preservative plus a wood stabilizer, offering the natural beauty of real wood combined with dimensional stability and weathering protection. This reduces cracking,checking, warping and splitting. The Ecolife preservative is also a Green Approved Product by the NAHB Research Center and complies with the criteria specified in the National Green Building Standard. Plus, the treatment is no more corrosive to fasteners and metal fittings than untreated wood. However, even with the preservative treatment, applying a waterproof sealant to the wood will provide the best protection.

Strong Foundation

The lake house sits on a considerable slope, so we had to carefully plot our plan of attack. The flattest, most construction-friendly area to build the project was the relatively level and flat driveway. However, the driveway was nearly 50 yards from the lake, and we were building a 10-by-10-foot dock. We didn’t exactly have a crane at our disposal. If we were to build the whole thing on the driveway, we would not be able to lift it to the water. So, we compromised. We constructed this deck in phases to carefully manage the weight of the structure.

To ensure a flat, level frame on which everything else would be built, we assembled the four rim joists on the driveway. The 2-by-8 rim joists comprised the outside perimeter of the dock. Each corner was bolted together with eight 1/2-inch lags along with inner and outer galvanized plates.We centered each of the plates mid-height of the joists, and we found that it helps to clamp the plates in position while you drill the holes for the bolts. You can always tighten the nuts and bolts with a socket wrench, but we used a powered impact wrench that saved us hours of labor.

When assembling, it is critical that each rim joist is square and level so take any means necessary to make sure this happens. We used everything from scrap lumber to landscape pavers as shims to keep the frame in shape while we fastened the four corners.

Once the square perimeter of rim joists was complete, we carried the dock frame closer to the lake onto a paver patio where we installed the interior joists.

Joist Placement

When building a dock such as the one shown, there are two things to consider when determining joist placement: (1) the size of your deck boards, and (2) the mounting locations of your flotation devices.

Full 2-by deck boards can be installed over joists spaced on24-inch centers. However, this project was decked with 5/4 decking boards,which required a tighter joist span of 16 inches on center.

The flotation devices were designed to be installed with 1/4-inch stainless steel lag screws through four corner mounting holes and into the lower edge of the deck joists. First, we measured the distance between the mounting holes on the dock floats, and fastened the corresponding joists so they exactly matched the spacing of mounting locations. Once these critical joists were installed, we located the remaining joists 16 inches from their centers. It’s important to orient the joists with their crowns facing the same direction to provide an even nailing surface for the deck boards.

Like the rim joists, the deck joists were installed with a combination of lag bolts, nuts, washers and galvanized plates. The plates include an L-bracket to fasten the joists to the rim lumber, as well as two smaller plates that sandwich the joists to the bracket. The hardware provides a solid and secure connection that resists tension and twisting within the dock frame.

To provide some extra structural integrity, we cut blocking from 2-by-8 material and fastened the blocks between the center joists of the dock that would not be bridged by the flotation devices.

With all the joists assembled, the dock had accumulated a great deal of weight. At this point our team of five Extreme How-To staff members carried the completed dock frame even closer to the lake, where we attached the six flotation devices to the joists.

The flotation units added even more weight to the structure,and the dock was upside-down. We needed to flip over the dock to have the floats on the bottom. To do so, we recruited a Jeep with a front-mounted winch.Our crew was able to stand the dock upright on its side while our winch operator helped to ease the dock down gradually, so it didn’t crash on top of us. Once flipped, the dock was roughly 8 feet from the water in preparation of launch.

Decking the Dock

We needed to install at least some of the deck boards overland to provide a working platform on which to install the remainder of the decking on the water. When installing the decking, be sure to check the ends of the 5/4 boards and install them with the “bark side” of the wood facing upward to reduce the chance of cupping. We fastened each deck board with stainless steel deck screws from GRK Fasteners, two per joist. We love the GRK screws because they’ve got unmatched holding power and the heads never cam out—a real timesaver.

Driving the fasteners with an impact driver proved to be the quickest method of installing the decking. For bowed boards, we used the board-straightening BowWrench from Cepco Tool, which clamps over a joist to leverage the bowed board in straight alignment with the installed decking (www.cepcotool.com).

We installed about a third of the boards to give us a floor on which to work, but we didn’t want to complete the deck until we got the dock in the water, so as not to add any more weight than necessary.

At the time of construction the water level was low, so rather than sliding the dock easily into the water, we had to make the transition over the sheer ledge of a 3-foot seawall. This was an awkward affair in which we used 2-by-8 boards as makeshift ramps and the winch to keep the weight of the dock manageable as we eased it into the water.

Mounting the Dock

The property had two piers. One was home to the dilapidated older dock, the other was a narrow, shorter fishing pier that would serve as the gangway to the new dock. To mount the dock, we used two large pieces of hardware called “Chain Pile Holders,” which are equipped with a chain to wrap the piles (support posts) of the existing pier and prevent the dock from floating away from the shore. These heavy-duty, L-shaped galvanized brackets required eight through-bolts and washers each.

To center the dock on the pier, we measured between the two posts that would hold the dock in place. The center of the posts had a 64-inchspan. We then marked the midpoint of the dock on its “mounting” side, and measured 32 inches to each side of the center mark, where we made new marks that indicated the midpoints of the Chain Pile Holders to ensure they aligned with the posts.

Sixteen bolts and washers later, the Chain Pile Holders were in place. We paddled the dock over to the posts and wrapped them with the chains to anchor the dock in place. The chains fit loosely around the piles,keeping the dock in place but providing enough slack so they can slide easily up and down the posts as the water level rises and falls.

Trim Package

The final phase of the dock project was to add vinyl docktrim to the three edges that were not connected to the pier (supplied by TaylorMade Products, www.taylormadeproducts.com). The trim package starts with 6-by-6-inch vinyl corner bumpers, which we top-fastened to the deck with the stainless steel GRK screws. The trim strips that fit between the corner bumpers are called dock bumpers, and we used a hacksaw and snips to trim them each to fit flush between the corner pieces. The bumpers are manufactured with a tough PVC inner core that is surrounded with softer white vinyl, providing a cushion for boats, jet skis and people climbing up the side of the dock. Like the corner trim, the bumpers fasten to the top of the dock with stainless screws and provide a crisp, finished look to the new dock.

With a team of five guys firing on all pistons, we managed to complete the dock and send it swimming despite its heavy weight. It was tough work, but we wrapped up the day with cold beverages and barbecue ribs and now have a new place for fun in the sun.