Architectural trim can define a home’s interior decor. Beyond the basic structure, trim and molding make a dramatic impact on the style of the living quarters. Doors and windows are perfect candidates for a trim upgrade when remodeling a home. And most of today’s home-improvement stores offer a wide variety of the most popular trim and molding profiles for doors and windows. These trim pieces come in a variety of lengths and sizes, often made of paint- or stain-grade pine. Many fiberboard selections are also available pre-primed and ready to paint. These pre-molded trim pieces are perfectly suited for the DIY’er who is anxious to add some class to their interior décor.

First remove any old trim and Rip the stool plate to width.

exposed nails.

Window Sill

On the window shown in this article, we removed the thin casing trim when we repainted the room. We decided to trim the rest of the room in white to offset the dark tone of the chocolate brown walls. We began the new trim installation with the most basic of window framing and added a sill (often called a stool) and jamb extensions.

First came the sill, which I ripped from 1-by (3/4-inch) poplar. Poplar is an excellent wood for trim work— easy to work, easy to find and relatively inexpensive. I use it for most trim components that don’t have a decorative shape. The framing for this window required that I ripped the sill to 3-5/8 inch wide, but the sill dimension will depend on the construction of your particular window. Generally speaking, you want the sill to extend slightly beyond the face of the window casing, so the casing pieces can “sit” on the sill with no overhang. Many sills also extend slightly beyond the sides of the casing—but the design is really up to you.

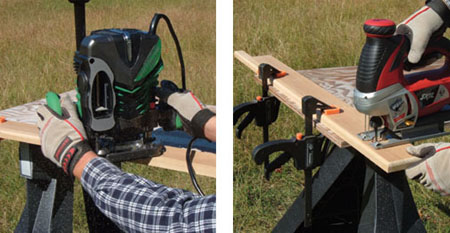

Rout a decorative profile on the front Cut notches in the rear of the stool

and sides of the stool plate. to fit around the window framing.

After ripping it to width, I used a router with a round-over bit to give the board a curved nosing on the front and sides. Make several shallow passes with the router to achieve a smooth cut. Next, I used a jigsaw to cut out square notches in the rear corners, measured to fit snugly around the window frame and wall. Install the sill with countersunk wood screws and wood glue. Make sure it is level; if it’s not then adjust with wood shims until it is, and fasten securely. There should be plenty of clearance between the sill and the window latches.

Attach the stool with countersunk screws. Then cut the jamb extensions to fit flush between the stool and upper framing. Make sure they are plumb!

Jamb Extensions

The jamb extensions line the interior frame of the window, and I ripped them from 1-by poplar as well. The front of the jamb extensions should be installed flush with the face of the wall, providing a continuous flat surface on which to install the casing. Also, provide plenty of clearance on the rear side of the jambs so they do not prevent with the window sash from easily opening and closing. The jamb extensions for this project were slightly wider than 2 inches, and the width should match for the sides and the top. I installed the side extensions first—flush with the sill and the top of the window frame—and then installed the top extension cut to fit flush between the sides.

House framing never seems to be A cordless 18V trim nailer

square. You’ll probably have to use made installation a breeze.

wood shims to adjust the trim.

You’ll likely have to deal with some framing imperfection when installing the jamb extensions. This means you need to square the extension jambs with wood shims. (See the sidebar on working with wood shims.)

Casing and Corners

For the leg and head casing pieces, we chose a fluted wood profile. I also added 3-1/2-inch rosette blocks at the corners. When installing the casing pieces, each piece should bridge the edge of the underlying jamb extension, but not completely conceal it. Use a combination square or trim gauge to keep the reveal consistent throughout the casing. I left 3/8 inch of the jamb extension exposed at the sides and top of the window.

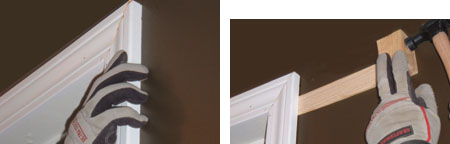

Keep a consistent reveal where the Center the rosette blocks and nail

casing laps the jamb extension. in place.

Also, before installing the casing, carefully measure and test-fit the leg pieces and corner blocks. For this style of installation, the head and leg pieces should intersect flush with the rosettes and centered on each side. Once everything is level, plumb or otherwise copasetic, fasten the legs in place, then follow with the corners and top. I used a cordless trim nailer for all the casing and corners (make sure to fasten into solid framing).

Fasten the head casing flush between I cut mitered returns on each end

the blocks. of the apron.

Apron

The trim piece below the sill is called the apron, and it’s often made of simply a flat painted board. But for this project I used a spare lenth of brick mold, which has a preformed profile. The brick mold was originally too thick for this application, causing the face of the brick mold to stick out beyond the front of the sill. So I ripped some of the width off the rear of the molding and nailed it in place, into the window’s lower framing plate. I also cut mitered returns for each side of the apron for a finished look, and fastened those to the ends with nails and wood glue.

Nail the apron into the framing Finish up with wood putty, sanding,

just beneath the sill. priming and painting

With the apron in place, you’re almost finished. Fill the nail and screw holes, sand the dried putty and caulk the seams. Prime where needed, and coat everything with a high-quality interior house paint.

Working with Wood Shims

One fact of life in home-improvement is that house framing is often not plumb and square. As seen in this article, when installing window jamb extensions, you may find that when placed flush with the window framing the top extension is slightly askew. Or maybe, the side extensions lean to the right or the left. If this is the case, insert thin wood shims between the extension piece and the window framing until the extension is level or plumb. Shims are beveled, so only insert the thin front end to make small corrections. Push the shim further into the gap to adjust for more space. Use enough shims to provide solid backing, and then fasten the extension in place with countersunk wood screws. Use a hammer and chisel to cut off the excess wood shims.

With door and window casings, uneven walls can cause mitered corners to gap open where two pieces meet. If this is the case, try inserting shims behind the casing, between and the trim and the wall, to push the miter joint closed. Use wood glue and trim nails at the joint. Fasten the casing in place. Chisel away the excess shim material and hide the exposed shims with a bead of caulk or another piece of trim.

You can pick up a pack of wood shims at most any hardware store for about two bucks. They provide an easy, inexpensive way to fine-tune trim carpentry.