Table saws are excellent tools for making clean, accurate cuts.

If you’re serious about woodworking, then you’re well versed in the wonders of a table saw. And if you’re new to woodworking, or interested in picking it up as a hobby, then you’ll find that a table saw is one of the most versatile woodworking tools available. Table saws can be used for crosscutting, miter cutting, bevel cutting, compound miter cutting, ripping, bevel ripping, rabbeting, resawing and molding. Because it’s so versatile, a table saw often serves as the “flag ship” tool of a home workshop. With a table saw, a circular saw blade protrudes through a smooth table surface, cutting stock as you feed it into the blade. Since the user guides the stock into the blade, rather than the blade into the stock, table saws offer supreme control and accuracy for a huge variety of cutting chores.

The Basics

Modern table saws feature an adjustable blade that can be raised or lowered within the table to accommodate a variety of cutting depths. Blade height (the amount of blade protruding above the table surface) is typically adjusted with an elevation wheel. Turn the wheel to raise or lower the blade. The elevation wheel also pivots, and locks and unlocks its position. The pivoting action tilts the saw blade from zero to 45 degrees to make bevel or straight cuts. The motor and blade are usually housed beneath the table surface, which is constructed of smooth steel to facilitate easy sliding of stock over the work surface.

Table saws vary in size, features, engineering and capacity, ranging from smaller benchtop models to large, expensive “cabinet” models used by professional woodworkers. Table saws can operate on a direct-drive, or be driven by a single V-belt, a serpentine belt or multiple V-belts. Contractor saws—the type most used by homeowners and the focus of this article—feature three primary accessories that help with operation: a blade guard, a miter gauge and a rip fence.

The blade guard, which covers the blade, not only provides a barrier between the blade and your hands but protects the user from flying debris. The blade guard should always be in place when making cuts where the blade penetrates completely through the workpiece. A splitter is also an important feature and is configured as part of the blade guard. A splitter, or spreader, is a thin fin of metal positioned in line with the rear of the saw. Its purpose is to prevent the cut piece from rotating, preventing kickback. Plus, the splitter usually has two anti-kickback wings with sharp teeth. When the workpiece moves toward the user, the teeth dig into the stock to hold it safely and securely.

Table saws have one or two grooves in the table surface, running parallel to the blade to position the miter gauge. When crosscutting, the miter gauge is usually set at 90 degrees to the plane of the blade to cut the workpiece at a right angle. Of course, the miter gauge can also be adjusted and locked in position to cut precisely controlled angles, or miters. A good miter gauge should have stops at 45 and 90 degrees and swing to both sides.

The rip fence is a guide that runs from the front to the rear of the table, perfectly parallel to the blade. The distance of the fence from the blade can be adjusted, and it guides the workpiece when ripping stock to width. A good rip fence will be solidly constructed with a firm fit in every position on the table surface.

Using the Miter Gauge

The miter gauge will be your go-to tool for making crosscuts, miter cuts, bevel cuts, compound miter cuts and when making rabbets across the end of a workpiece. When using the miter gauge, first clear the table surface of the rip fence and any other accessories, scraps or debris. While the motor is off, set the blade height to cut about 1/4 inch through the stock. Measure and mark the cutline on the workpiece, and align the mark with the cut indicator on the saw. If crosscutiing, lock the miter gauge at a 90-degree angle to the blade. If miter cutting, lock the miter guage at the desired angle using the marked graduations. Hold the stock firmly against the fence and stand to either side of the saw (to avoid any debris that may be thrown toward you during cutting). Turn on the saw, and with a steady, smooth motion push the miter gauge and workpiece forward, so the stock moves into the blade. Be sure to keep your hands out of the path of the blade. Note: You may want to glue a piece of sandpaper to the head of the miter gauge to prevent the workpiece from slipping around. Also, if the workpiece is warped, then place the concave side facing down. This helps prevent it from rocking while being cut.

When making bevel cuts or compound miter cuts, use the same process but adjust the tilt of the blade to the desired angle using the graduations marked on the blade tilt control. Adjust the tilt and lock it securely.

Homemade stops are useful when you want to cut a number of pieces the same length without having to mark each piece. Never use the rip fence as a length stop because the cut-off piece could bind against the blade and cause kickback. Instead, when making repetitive cuts, you can make a stop by clamping a 3-inch block of wood to the table at the desired length. Make sure the stop block is well in front of the blade and clamped securely.

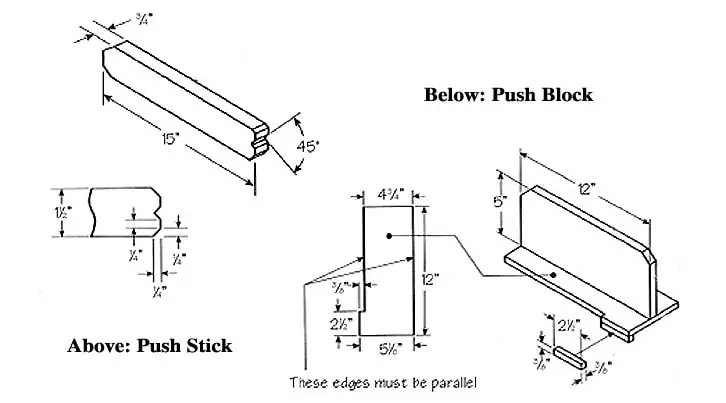

When making cuts with the miter gauge, one rule of thumb (if you want to keep yours) is to complete the cut, pull the workpiece back and push the cut-off piece off the table with a “push stick”—don’t use your hands. Also use the push stick to remove small cut-off pieces from the table surface, otherwise they could be thrown back toward you by the spinning blade. (Check out the diagram below to learn how to make a push stick.) Always keep your hands away from the blade and never make any cuts freehand (without using the miter gauge, rip fence or other auxiliary device). And anytime you’re cutting a long piece, make sure to support the cut-off end from the floor.

Using the Rip Fence

The rip fence is an indispenable tool for ripping, bevel ripping, rabbeting along the stock’s length, or resawing. Always begin by clearing the work surface of the miter gauge and any other obstacles or debris. Set the blade height and position the fence according to the width of cut. Most modern saws feature a graduated scale on the edge of the table to line up the rip fence’s pointer, which indicates the measurement between the blade and fence. Some saws also feature a dual scale equipped with a secondary pointer and an extendable table for making cuts in wide materials. Either way, always lock the rip fence securely to the table when using it.

When ripping, always make sure the rip fence is parallel with the saw blade, and the splitter, or spreader, is properly aligned with the blade.

For standard ripping, use both hands to push the stock forward and firmly against the rip fence, guiding the workpiece into the blade. The blade should be set to cut 1/8 inch beyond the surface of the stock. Bevel ripping is done in the same manner, but with the blade tilted to the desired angle and locked into place. Use a “push stick” to push the workpiece completely past the blade to complete the rip. Remember to cut warped stock with the concave side down. And when ripping long boards or panels, always use work support such as an outfeed roller, or a sawhorse clamped with a sheet of plywood at the proper height to support the work evenly.

Homemade Gadgets for the Table Saw

Push Stick: A push stick is a simple tool made from a 15-inch piece of wood with beveled and notched ends to nudge the end of a workpiece past the blade and off the table.This is an important safety tool used for ripping and bevel ripping, as well as clearing the table of wood scraps.

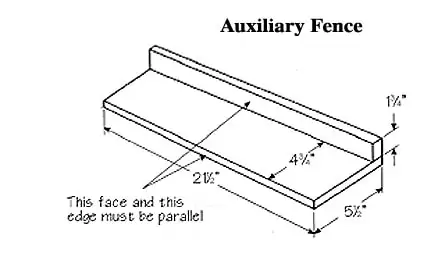

Auxiliary Fence and Push Block: In some cases of very narrow rips, such as less than 2 inches wide, a push stick can’t be used because the blade guard interferes with it. In such a case, you can build an L-shaped “auxiliary fence” about 5-1/2 inches wide and long enough to fit your table surface (see page 20). Clamp the L-shaped lip to the rip fence with two C-clamps. The lower side of the auxiliary fence acts as an extension of the rip fence, only with a lower profile to guide the stock by sliding beneath the guard for closer proximity to the blade. Feed the stock into the blade by hand until the end nears the edge of the table, and then use a “push block” to complete it.

A push block is built to fit flush over an auxiliary fence as a sliding guide. It has a handle in the middle and a small piece of wood is glued to the corner of its underside to push the end of the workpiece into the blade, completing the cut.

Auxiliary Fence and Feather Boards: The auxiliary fence can also be used to support “resawing” operations. Resawing is ripping a piece of stock through its thickness, like cutting a 2-by-4 into a 1-by-4. When the stock is stood on its side, it can be supported on either side by “sandwiching” the workpiece between the rip fence and the “L” side of the auxilary fence, which is clamped to the table surface. Don’t attempt to resaw warped material.

When resawing, often the blade won’t cut completely though the thickness of the wood. If this is the case, you’ll have to make two passes, one through each thickness edge. This can only be done with the blade guard removed.

In any cutting operation where the blade guard must be removed because the blade won’t be cutting completely through the wood, “featherboards” should be used. Whether rabbeting, dadoing or molding with a special cutting head, featherboards keep the workpiece firmly pressed against the fence and table. Featherboards can be clamped above and to the side of the workpiece. The kerfed, leading edges of the featherboards exert pressure on the workpiece until the cut is complete.

Auxiliary Facing: In some cases you may want to attach wood facing onto the rip fence, whenever the cutting edge comes close to the fence, and you want to avoid the blade hitting the metal. Attach facing to the fence when using a dado or molding head, or when ripping very thin material. The auxiliary facing must be made of smooth, straight wood, about 3/4 inch thick, cut to the same length as the fence and attached with wood screws.

You can also attach wood facing to the miter gauge. When the auxiliary facing is longer than the face of the miter gauge, it provides additional support when cutting long pieces of stock.

Sidebar 1

Saw It Safely

Don’t be one of those people who assume they were born a power tool expert. Those people can get hurt. Read and understand the owner’s manual and labels affixed to the tool. Learn its applications, limitations and potential hazards.

- Dress appropriately when using a table saw. Don’t wear loose clothing or jewelry that can be caught in moving parts. Always wear eye protection and wear hearing protection when working long intervals. Use a face mask if the cutting operation is dusty and use a hair covering to protect long hair.

- Always disconnect the saw from its power source when it’s not in use, before servicing and when changing blades, bits, cutters, etc.

- Always keep the guards in place, in good working order and in proper adjustment and alignment.

- Don’t force the tool to do a job it wasn’t designed for. For example; don’t use your table saw to cut tree limbs or logs.

- Table saws should be bolted securely to a stand or workbench. Use the table saw in a well lit area and on a level surface. And always use auxiliary supports to cut long or heavy boards.

- In addition, if there is any tendency for the table saw to tip over or move during certain operations such as cutting long, heavy boards, use an auxiliary support.

- To avoid kickback, keep the blade and anti-kickback wings sharp. Keep the rip fence parallel to the blade when in use. Avoid cutting warped or twisted stock.

- Use a Push Stick for ripping widths of 2 to 6 inches and an auxiliary fence and Push Block for ripping widths narrower than 2 inches. Don’t release the workpiece until it has already moved past the blade. And never “back up” (reverse feed) the workpiece while resawing (with guard removed) because this could cause a kickback.

SIDEBAR 2

The Latest and Greatest

Bosch 4000

Bosch offers a real “Cadillac” of a table saw in its 4000 model. The 10-inch Bosch 4000 features a table surface of 29 by 21-1/2 inches, the largest in its class for easy handling of large stock. The 15-amp motor features Constant Response Circuitry that monitors torque demand and instantly delivers additional power to maintain constant speed under load. Plus, a “soft start” feature allows quieter, smoother start-ups. The rip fence is also top-notch, featuring patented “square-lock” technology that provides accuracy with every cut. The 4000 also boasts a heavy-duty steel, folding “Gravity Rise” saw stand that makes it easy to break down and set up for work. The stand comes equipped with treaded pneumatic tires. The Bosch 4000 isn’t cheap, but it’s worth every dime. Highly recommended for the serious table saw enthusiast. Check out www.boschtools.com.

Skil 3400

Skil’s Model 3400 10-inch, 15-amp table saw is not as decked-out in features as the Bosch 4000, but it still makes a reliable unit for homeowner use and also costs considerably less. In addition to the die-cast miter gauge and a rip fence with magnifying lens for reading measurements, the saw features on-tool storage for the blade, wrenches cord and accessories. The table has integrated carrying handles and soft grip controls. The Skil model comes with a 28-tooth carbide blade and is also available with a saw stand. Visit www.skil.com.