From deck-building to intricate finish carpentry, one of the most useful electric saws is a miter saw. If you’ve ever used a slow-going miter box and handsaw combo, then you probably get my drift. In fact, a miter saw is the single most important tool a finish carpenter will use, providing the critical angles to build inside and outside corners on virtually any project. If you’re new to miter saws, this article will take a look at some basic features and what they’re used for, as well as highlight a few models that are currently on store shelves.

Weighing the Options Before purchasing a saw, first decide what applications you’ll be undertaking. Then factor in storage and portability. And of course, work within your budget. For example, a professional-grade sliding compound miter saw will likely handle any chore you throw at it, and do so day after day for years to come. However, such a beast can be very expensive ($700), weigh more than 70 pounds and take up a lot of space. And I’ve never encountered a sliding compound saw that’s easy to carry. For a contractor or serious DIY’er who uses a miter saw often, such an investment makes sense. But, for the occasional trim-out around the home, a smaller consumer model should suffice.

In fact, professional trim contractors don’t always ascribe to the “bigger is better” theory. Blade size typically ranges from 7-1/4 to 12 inches, and the smaller saws are much lighter and thus easier to carry and store. This is a big advantage when schlepping the tool from jobsite to jobsite. Naturally, the trade-off for a smaller size is work capacity. The larger the blade, the larger the material it can cut.

The Right Type Miter saws also vary in the type of cuts they can make. A standard miter saw—often called a “chopsaw”—cuts stock with a downward chopping action. You can make standard crosscuts or turn the saw to cut a miter, usually anywhere from 0 to just over 50 degrees. This style works fine for “flat” work, such as making door casing or picture frames.

Compound miter saws are more versatile. Not only can you turn the saw for a miter, but you can tilt the blade to cut a bevel. A compound miter saw can cut a bevel on any miter angle simultaneously. This dual cutting action is critical when working with crown moulding, base moulding, etc. To further complicate matters, let’s divide compound saws into two categories: single bevel and dual bevel. The single bevel saw can flip to one side for making compound cuts. A dual bevel can flip to either the left or the right. The dual-bevel saw provides the widest range of angles. The advantage of the dual bevel is that you can cut trim stock with the bevel and miter oriented the same way it will be installed, which can save you both time and some mental acrobatics.

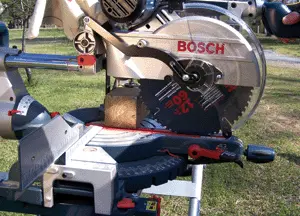

A 12″ sliding compound miter saw, such as the Bosch 5412L shown, has plenty of cutting capacity for dimensional lumber.

However, the most cutting capacity comes from the sliding compound miter saw. Instead of cutting with a chopping action, these saws slide out from the saw’s base on rails. The user activates the blade and then slides it back through the stock, cutting in reverse. Many new models are belt-driven, which keeps the motor conveniently out of the way when cutting. Sliding compound miter saws usually cut up to 5-1/4-inch base or crown in position (with the moulding angled against the fence and base, which represents the wall and ceiling of the house). For anything bigger than that, you’ll have to tip the blade at a bevel and cut a compound miter. Not only can the sliding saws conquer all the trimwork you can dish out, but they have the capacity to cut large dimensional lumber, making them ideal for building decks, stairs and fences.

Ryobi offers a 10″ sliding compound miter saw at a consumer-friendly price.

Adjust its bevel angle by turning the handle on the rear of the saw.

Using the Saw When preparing to use a miter saw, take note of the super-sharp, toothy blade that spins at speeds up to 5,400 RPM. Suffice it to say that safety should be a top priority when operating the saw. Always wear safety glasses and clear away any wood scraps or debris from the saw area.

Ridgid’s MS1290LZ features an extra large base.

First, adjust the head to the designated angle. The miter angles are printed on the base of the saw, and you generally slide the saw handle and its indicator to the designated degree. Screw in the handle to tighten the saw into position. The bevel-adjustment device is often located on the rear of the saw, and operates in much the same manner with a bolt/handle to tighten to the correct position and demarcated measurements to guide the angle setting. Some of the newer saws offer bevel locks on the front of the saw, so the user doesn’t have to reach to the rear. Another neat modern feature is a backlit digital display that shows the exact angle setting for both miters and bevels, which gives you much better visibility and confidence that the blade is set to the right position.

The large base of the Ridgid saw has the capacity for 61-degree miter cuts…

When you’re ready to cut, stand in a stable position and use one hand to hold the material tightly against the fence and downward against the table. Many new saws include special clamps that help firmly secure the stock in position to cut. Always hold the workpiece portion of the stock, not the short cut-off piece. Use the other hand to operate the saw, and steadily push the blade down into the stock. Always release the trigger and let the blade stop completely before raising the handle from the workpiece. This will keep the spinning saw teeth from chattering against the surface of the material as it is pulled up from the cut, which can mar your work. If stopping the cutting operation halfway, start re-cutting after you pull the saw head back into its original start position.

… and 47-degree bevel cuts.

If using a sliding saw, pull the blade forward as far as it will go before plunging it into the wood. Pushing the cut allows the rotational force of the saw to work with you. Never pull the blade toward you through the stock—it’s dangerous and will result in a lousy cut.

Hitachi’s C12LSH miter saw features a backlit digital display of the miter and bevel angles.

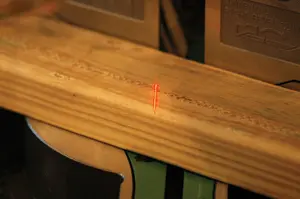

Some saws feature an laser line to mark the miter cut.

A miter saw with an accurate setting means there’s no real need to mark a cutline the entire width of the stock. A simple, penciled “V” mark, with its point indicating the cut-off point is all you need, and will speed up the process when making multiple cuts.

A V-shaped pencil mark is really all that’s required to mark a miter cut.

For precision cutting, it may help to start the cut ahead of the “V” mark, gradually shaving away material until reaching the cut-off point. Some of today’s saws even provide a precise laser sight-line that indicates exactly where the cut will be made.

I used to cut picture frames as an evening job during college, and in doing so I found that some moulding profiles tended to tilt ever-so-slightly forward beneath the pressure of my hand. This caused the miter to be slightly uneven in the back of the cut, resulting in a small gap that I’d have to fill with putty. To minimize this, I found it helpful to use a small wooden block, pushing it with the ball of my hand against the bottom of the moulding, securing it against the fence as my fingers pressed the stock downward. This helped prevent that slight tilting.

For repetitive cutting, using stop blocks will speed up the cutting. Shown is the Bosch Gravity Rise miter saw stand that includes integrated stop blocks and also folds into a portable cart.

For multiple cuts of the same length, such as studs, balusters, pickets, etc., you’ll find it helpful to secure stop blocks at the end of the saw’s table or stand. These hold the end of the material in a uniform position while you make the repeated cuts. Many manufactured miter-saw stands feature adjustable stops and “wings,” or outfeed supports, that extend to accommodate long pieces of material. Or, a makeshift stand can be made of a sturdy piece of plywood clamped to sawhorses on a level surface. Just make sure the wood stock is evenly supported so the piece does not bow. You can also make your own stop blocks.

Current Models

Bosch 5412L 12” Slide Compound Miter Saw The last couple of months I’ve had the pleasure of using the Bosch 5412L sliding compound miter saw, and it offers a little bit of everything. Accurate right out of the box, the saw’s 12-inch blade, powerful motor (3 horsepower), and beefy dual slide rail make quick work of cutting everything from quarter-round to fence posts. It can crosscut boards up to 4-1/2 inches thick by 12 inches long. When set at a 45-degree miter, it cuts up to 4 inches thick by 8-1/2 inches long. At a 45-degree bevel, the cut capacity is 2-3/4 inches by 12 inches. The 5412L also features a four-position handle, up-front adjustments of all bevel and miter settings, an easy-to-lock work clamp, two sliding fences, dust-collection bag, and sliding extensions that support boards up to 40 inches long. The motor is equipped with an electric brake that stops the blade within a split second of releasing the trigger. The saw’s arbor-mounted laser provides a bright, thin laser line that is visible throughout the cut, so you can perfectly match the cutline to the blade kerf. Because I do a lot of work away from home, a really sweet accessory to the Bosch saw is the Bosch Gravity Rise miter saw stand, which folds into a pneumatic-wheeled carrying cart when not in use. This makes toting the saw from site to site much easier on the back. www.boschtools.com

Ridgid MS1290LZ 12” Slide Compound Miter Saw The first thing that struck me about Ridgid’s new slide miter was its large, extra stable deck with a cool flip-up miter adjustment handle. Rotating the handle’s thumbwheel away or toward the table engages or disengages the positive stops, in case you’re setting angles very close to the detents (i.e., 44.5 degrees next to the 45-degree detent). Plus, the large deck means the saw can pivot left and right for cuts up to a best-in-class 61 degrees. You can also tilt the saw head from 0 to 47 degrees on each side. The laser blade locator is spot-on, the 2-1/2-horsepower motor has a good start-up, and even the hold-down clamp is solidly constructed and easy to use. A depth-stop feature allows you to cut rabbets or grooves. As far as dust collection, I prefer the cosmetic appeal of Ridgid’s metal-framed dust bag when compared to the flimsy socks included with most competing saws. Overall, this is a solidly built, pro-grade saw that prices less than its major competitors—at time of publication, the Ridgid model ran just under $500, compared to the Bosch 5412L at around $675. www.ridgid.com

Portamate PM7000 The PM7000 WorkCenter takes the concept of multi-functionality to the next level. Benchtop planers, bandsaws, scroll saws, miter saws and more can now be used interchangeably. You can even mount and use more than one tool at a time thanks to the long bed and four-outlet power center. Universal machinery mounts snap securely to the aluminum top, making tool changes fast and easy. Standard equipment also includes three material supports, 8-inch wheel and a storage compartment. Extension wings let the woodworker handle workpieces to 16 feet. The new wheel system allows the user to easily roll the workcenter to a new location—no more lugging heavy saws or equipment around the jobsite. And, for a limited time Portamate is also including two great accessories for free! A free heavy-duty, cast aluminum work vise ($49.99 value) and handy work light with integrated machine mount ($19.99 value) make the Portamate PM7000 WorkCenter an outstanding value for the price of a basic miter saw stand (around $249).

Hitachi 12” Slide Compound Miter Saw

Hitachi’s C12LSH compound miter saw not only features a laser marker but also a digital LCD display. The digital display of miter and bevel angles requires the unit to be trued to ensure accuracy, but once this important procedure has been done and the saw fences are checked, you will be on your way to cutting with a saw that is, well, on the cutting edge. The digital angle finder worked fine for the samples we cut, and this feature should be very useful when cutting crown moulding. The handle layout was comfortable, and the sliding action was everything I would expect from a saw in this price range (approximately $650). One of the less touted features of the Hitachi was the ability to operate the saw in tight quarters. Hitachi’s rails do not require clearance behind the saw like other miter saws. Miter-cut ranges for the Hitachi C12LSH are 0-46 degrees to the left, 0-57 degrees to the right. Bevel range is 45 degrees for both left and right bevel. Our test saw was mounted on Hitachi’s Universal Stand—a well-made addition to any Hitachi Saw. Table weight is 40 pounds, so it is built to professional standards also. The inclusion of a wheeled stand is almost a necessity for the combined unit that exceeds 100 pounds, and thankfully, the Hitachi Universal Stand has wheels. www.hitachipowertools.com