From cabinet making to creating custom trim, routers are among the most sophisticated woodworking machines in carpentry. Handheld routers, both plunge-style and fixed-base, are popular among both professionals and DIY’ers for their ease of use and wide versatility. Whether you’re rounding over or hunting rabbets, an electric router can shape the wood just like you want.

You’ll find both pros and cons to the two main types of router: fixed-base and plunge style. A fixed-base router has the tool’s base plate attached in a fixed position to the motor, which is a great setup for cutting a profile in the edge of a board, as well as any application where the tool cuts from outside toward the board. Although somewhat limited in use, fixed-base models have less moveable parts than plunge routers, which sometimes makes them easier to use in conjunction with accessory guide bushings. Smaller trim routers take advantage of the fixed-base design to cut down on tool weight, which makes them easier to maneuver.

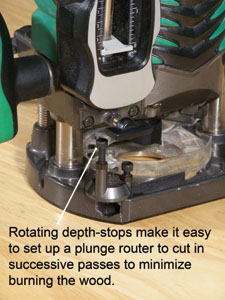

In general, plunge routers can do everything a fixed-base can do, and more. The motor and cutter head slide along guide bars attached to the base. Plunge routers can begin the cut in the center of a piece of wood, where the router bit is lowered or “plunged” into the work piece. The plunging action makes the tools suitable for routing mortises and cut-outs in the center of stock. Plus, a plunge router can be used as a fixed-base router by simply locking the motor in the desired position along the plunge bars. However, plunge routers are usually more expensive and heavier than fixed-base models, and some plunge routers can be difficult to adjust when upside-down in a router table.

Variable speed control is a common feature among plunge routers, and on certain fixed-base models. Variable speed allows you to adapt cutting speed to the wood and router bit, and it keeps the speed consistent even when cutting fast into the grain. This prevents burning the edge of the wood when cutting across the grain at a low feed rate.

One of the newer advances in router design is the combination kit, which includes a single motor with two detachable bases. Available from companies such as Skil and Bosch, router combo kits offer advantages of each base design; just pop on the fixed base for edging, or use the plunge base for grooving inside the work piece.

Sizes, Styles

When it comes to choosing a router, bigger isn’t always better. As with most any power tool, the larger machines produce more power and cutting capacity, but the extra girth and weight can be a problem on intricate jobs that require a steady, delicate touch. On the other hand, small trim routers won’t have the power to tackle heavy-duty chores like stair building and pattern cutting. Router sizes can be broken down into three groups: less than 1-horsepower; up to 2-1/4 horsepower; and over 2-1/4 horsepower.

The motor of plunge routers moves along guide bars to lower the cutter into the surface of the work piece. The heavy-duty 3-1/4-peak horsepower Hitachi M12V2 Router shown has plenty of muscle to operate large cutters with 1/2-inch shanks for deeper cuts in fewer passes.

The smallest routers, called trim routers, have a cutting-speed advantage over a regular router. The bit rotates faster, the compact size translates into greater precision on small jobs, and many trim routers can even be used one-handed. These units are ideal for edging plastic laminate, as well as basic groove and cutting work.

Routers in the neighborhood of 2-horsepower are a standard size among hobby woodworkers and professionals alike. One of the main advantages of the jump in power is that the motor can drive router bits of larger shank sizes, from smaller 1/4-inch bits to the larger 1/2-inch size. The thicker shank size of the bit gives it more rigidity so the cutter head can be manufactured in a larger size. The larger bits allow a deeper cut in a single pass, and you’ll also find a broader selection of profiles among larger bits. Router bits are also available in metric shank sizes, the most common being 6, 8 and 12 millimeter.

Above and Below: Trim routers are compact and have a cutting speed advantage over many larger routers. Festool’s new MFK700 Trim router has a unique adjustable base that can be configured with a standard vertical base, or convert it to a horizontal base. The 1.5-degree horizontal base is designed for trimming edge banding without damaging the work surface.

The largest handheld routers hover around the 3-1/4-horsepower mark and these high-production units can cut fast and hard. These big routers can easily power the largest specialty bits for tough chores such as milling frame-and-panel doors. The big motors are also suited for professional—meaning continuous—use. This means they’re very durable, but high-priced to match.

Edge-routing bits have a ball-bearing guide to ride along the edge of the work piece for an even, consistent cut.

The style of the base and handle offer more design choices. Handle styles vary from double doorknob handles to D-style handles and pistol-grip handles for easy edge trimming. Choice in handle style simply boils down to personal preference.

Bits with 1/2-inch shanks can support large cutting heads for tought jobs such as milling frame-and-panel doors.

As far as base plates, some have a round shape while others have combined straight and circular edges. The straight edge allows working closer to a vertical obstruction. For use in a router table, it’s also important that the base has threaded sockets through which to mount the inverted router.

Bits and Pieces

You can split router bits into two categories: edge routing and groove routing. With the help of ball-bearing guides, various edge bits can round-over a stair tread, cut a rabbet on the edge of a cabinet case, rout a decorative ogee in custom trim, or bevel the edge of a shelf with a chamfer bit.

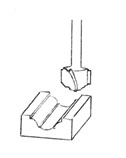

With no guide bearing in place, groove routing bits can cut inside the field of the work piece. For example, cut a mortise with a straight flue bit, or cut dovetail joints with an inverted V-shaped bit.

Plunge bits have no ball-bearing guide, so they can cut grooves, mortises and more, right on the face of the stock.

Most router bits are manufactured from high-speed steel (HSS), some are coated with titanium nitride to reduce friction and heat, but the best are tungsten carbide tipped (TCT) for longer cutting life. The HSS bits work well for softwoods and are much less expensive than the TCT bits, but they won’t last nearly as long. The harder TCT bits are necessary to cut hardwoods, plywood and other engineered wood panels.

An edge guide is an excellent accessory for routing parallel to the edge of the work piece.

When selecting bits, you’ll also come across spiral bits. The spiral cutters are designed to rout woods that tend to splinter a lot. The cutting edge of spiral upcut bits pulls the chips up and away from the work piece. With spiral downcut bits, the downward shearing action helps achieve a chip-free surface on chip-prone materials.

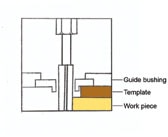

A guide bushing rides along the outer edge of a template (attached to the top of the work piece with double-sided tape), while the cutter copies the profile on the work piece. The general rule is to leave 1/8 inch of space between the cutting edge and the lip of the bushing.

As far as router accessories, make sure the router has a fine-adjustment device that allows you to alter the cutting depth by just a hair if necessary. A guide fence is also a handy item, which works just like a ripping gauge for a circular saw. The fence helps to hold the router on a straight path while making grooves or rabbets parallel to the edge of the wood. A good fence should be constructed of metal and attach to the base plate with rods and lock screws. A dust-extraction port is another handy feature, allowing you to hook up the hose of a shop vacuum to keep the worksite cleaner.

For routing templates, one of the most important components of a router is the guide bushing system. The guide bush serves as a spacer between the cutter and a template for grooving and edge trimming. The guide bush is basically a lipped collar screwed onto the router base over the bit. There are a variety of lip diameters to match different bit diameters. The general rule is to leave 1/8 inch of space between the cutting edge and the lip. The guide bush rides along the outer edge of your template (attached to the top of a work piece with double-sided tape), while the cutter copies the profile on the work piece.

With a router table you can fix the position and height of the cutting bit to pass stock through the cutter against a fence or jig, rather than running the router over the stock. The model shown is the Portamate PM7010 Router Table, which has an offset T-slot fence, a miter guage and fingerboard accessories.

Lastly, the use of a router table can convert your router into a miniature molding machine. You can fix the position and height of the cutting bit and pass stock through the cutter against a fence or jig, rather than running the router over the stock. The table gives the user an unobstructed view of the work, and makes it possible to rout small, intricate pieces where a router would otherwise be awkward to push over the stock.

*Lead photo courtesy of RYOBI™