How We Designed a Custom Trim Package and Fastened it to Masonry

By Rob Robillard

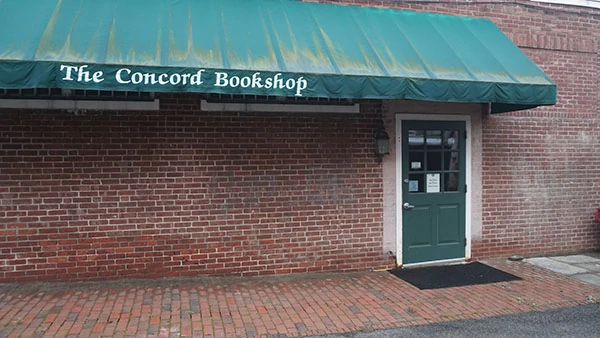

We were recently asked to dress up the rear entrance of the Concord Book Shop with a custom door surround. The brick surrounding this door had some sort of pink paint that the building owner wanted to hide. The ultimate goal was to create nice looking custom door surround that complemented the building’s front entrance.

Design

I decided I needed an 8-in. surround in order to cover over the pink paint. The best way to accomplish this was to utilize 8-in. wide columns and a simple classic flat-head entablature with crown molding. Our design was similar to a Georgian door surround but with much less detail and flat columns.

For plinth blocks we would match the column block on the front of the building, matching the profile with router bits we had in our shop.

Door Surround Materials

There are many commercially available products that can be ordered or custom made. We were not able to pursue those options, as the local Historical District Commission preferred we use real wood and not PVC. We decided to make this entire surround out of 1×4 and 2×10 cedar wood. Cedar has an inherent insect- and rot-resistant quality that seems to last. Plus, this door surround is protected by an overhead awning.

Both the columns and header trim had to be able to cover the treated plywood backer board. To accomplish this, we ripped 1-in. strips of cedar and glued and fastened them to the sides of the columns, plinth blocks and all four sides of the head detail.

By using a 1-inch return strip on all the custom door surround trim, we would ensure some space between the PT plywood and the cedar for seasonal wood movement and to act as an air/drainage plane.

We then would install stainless steel trim screws discreetly through the side strips and into the plywood backing.

We left the columns long to trim them on-site to account for out-of-level grades.

The Plinth Blocks

We needed two plinth blocks. Originally plinth blocks were masonry support bases, but have since evolved into more of a decorative add-on for many interior decors. Plinth blocks add a touch of style and class to a room. Plinth blocks act as a decorative base for door trim, pilasters or columns. They often stand proud at the bottom of the casing. Plinth blocks also add a reveal and shadow-line depth between the vertical and base trim, adding a nice aesthetic detail.

We used 2×10 cedar, ripped clean, sharp edges and then glued and clamped 1-inch returns onto the block. Once the returns had dried, we cut the plinth blocks to a rough size and routed a half-round profile to the top end.

Building the Header

The header was designed to protrude out 1/2 inch on both sides of the column trim as well as the door frame. We applied 1-1/4 in. returns to the rear of the header trim and then applied a solid molding (similar to a crown molding detail) to the front top edge. We glued, clamped and fasted this together.

Sanding and Priming

We filled all defects and sanded the wood thoroughly. Once done we wiped the wood down and applied a coat of exterior primer to all sides of the wood.

Attaching Trim to Brick

In order to attach our trim to the brick, we decided first to mount 3/4-in. pressure-treated plywood to the three sides of the door. The plywood would be rot-resistant and act as a nailer board for my trim fasteners.

We started assembly by getting the plinth blocks to sit correctly on the door frame and level with each other. We accomplished this with a long level, and also had to cut approximately 3/8 in. off one leg of each plinth block. This allowed the door side of the plinth block to overlap onto the metal door frame. This was necessary to have the plinth block be centered under the vertical column.

Once the plinths were cut and ready to install, we were able to place them against the wall as a dry fit. We used a long level to plumb a reference line for the pressure-treated nailer. Predrilling the treated plywood is necessary to get the masonry anchors to fit. Once complete, we held the PT board on the wall reference line and used a SDS Drill to predrill the mortar joints. We then installed the PT strips to the wall with expanding masonry anchors. We did this on both vertical sides of the door. We installed pairs of masonry fasteners approximately every 16 inches.

Tip: We initially installed only one top and one bottom masonry fastener and then dry-fitted the vertical columns. If adjustment was required we then tapped the PT board in the directions needed. Once perfect, we installed the rest of the masonry fasteners.

Attaching the Plinth and Column Trim

We pre-drilled, and then attached the plinth blocks to the plywood nailer with four stainless steel screws into the face of the blocks.

For the vertical columns, we dry-fit them onto the plinths to mark sure there was a tight seam. We also dry-fitted the head entablature to see where it would rest, in relation to the columns. We located that mark, and measured from the plinths to that mark.

The columns were cut, and the cut ends were primed. We also pre-drilled the return sides, attached the columns to the PT nailer, and then installed fasteners into the side returns for the column.

Attaching the Head Entablature

After the vertical columns were installed we measured, marked and installed an upper PT nailer. We then pre-drilled the entablature top, sides and bottom to receive fasteners, allowing for a 1/2-in. overhang left and right past the columns.

The final step on this project is to remove the mortar along a joint above the door and flash the top with a copper flashing head.

Editor’s Note: Rob Robillard is a professional carpenter and remodeler. Visit his website at www.ConcordCarpenter.com.