Jim Petrucci had a problem: Too many windows. A homeowner in Hartland, Michigan, Petrucci had plans for a new nursery, but he felt that the room he had in mind was overexposed to the elements.

“There were actually two windows in that room,” says Petrucci, “and it was just way too cold in the winter. And according to the code requirements for the area, one of the windows was too small to be the only window in a bedroom. We had to take one of them out, so we removed the window that didn’t meet code.”

Petrucci enlisted the help of a couple of friends, and over the course of a weekend they completed the remodeling job, creating a warm and welcoming location for the new nursery.

Deleting a Window

The first step in removing a window is to use a hammer and pry bar to remove the interior window trim. Then remove any exterior trim that is installed over the siding (or any other exterior wall covering).

Next, remove the exterior siding, starting with the J-rail along the top of the wall. It is fairly easy to remove vinyl siding. A zip tool — available from your local supplier — unlocks and later relocks the bottom of a panel so you can get at the nailing flange below.

Once the siding is out of the way, you can remove the window. Using a drill and a proper screwhead bit, remove the screws around the edges of the frame. When all the screws are out, remove the old window and frame. Petrucci’s window featured an aluminum frame and came out of the wall in one complete piece. It should be noted that all-welded windows are easier to remove than classic double-hung style windows, or other paneled wooden windows.

Next, scrape off all the old putty tape from the opening. Clean the opening thoroughly and caulk or use insulation to fill the old holes.

Patching the Wall

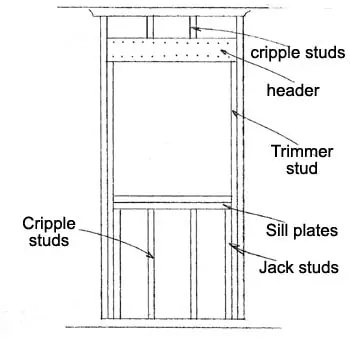

With the window out, you’re left with a large, square hole in the wall. To seal this area, you’ll need to build what is in effect a small wall within a wall. Begin by measuring the height of the opening from the header to the sill plate. Install jack studs cut to fit inside each side of the window opening, flush with the trimmer studs that frame the right- and left-hand side of the opening. Fasten all the framing components with 16d nails.

Continue framing the opening with studs spaced 16 inches on center. However, the studs should be laid out so the sheathing panels break at mid stud. This allows you to fasten the edge of the panel directly over the stud, providing a solid nailing surface for the seams. To do so will likely require that the second stud be positioned less than 16 inches from the edge of the framed opening (or jack stud). Make sure all studs are plumb and square.

As you progress, measure between each new stud and cut blocking to fit flush between the studs and flush with the bottom sill plate. Also, install similar blocking between the studs along the top of the frame, flush with the header or top plate.

With the wall framing plumb, square and blocked, it’s time to sheathe it. Cut sheathing panels to fit the rough opening. When attaching the sheathing, in this case 1/2-inch OSB panels, leave a 1/8-inch gap between the long edges of the panel and a 1/16-inch gap where panel ends meet. This allows room for the panel’s natural expansion. Use 6d nails for panel thickness of 1/2 inch or less and 8d nails for panels thicker than 1/2 inch. Nail through the panel and into the studs, all the way around the panel. Space the nails 6 inches on center around the outside edge of the panel. Space nails 12 inches on center on the interior of the panel.

Always work from one end of the sheathing to the other. Never nail all four corners of a panel before nailing the interior because this can result in bulges.

The next step involves installing a moisture barrier over the sheathing. Basically, this means putting tar paper or approved housewrap on the exterior walls before siding is installed. Proper installation is required to make this system work. You must design a drainage plane that keeps water out. The purpose of sheathing paper is to prevent drafts and the entry of wind-driven rain into the wall cavity. When water penetrates the siding, it must have a clear path to follow downward.

Begin by hanging the first sheet of wrap from the top of the opening. Secure the wrap every few feet with plastic-capped nails. Install the paper so that all water is directed outward. It helps if any paper above the patched opening overlaps the newly installed building paper. And, make sure the bottom of the “patch” paper overlaps the original building paper beneath it. Tape all seams in the barrier.

Re-siding the House

When it’s time to reinstall the siding, keep in mind the following guidelines from the Vinyl Siding Institute:

1. Installed panels must move freely from side to side.

2. When installing a siding panel, push up from the bottom until the lock is fully engaged with the piece below it. Without stretching the panel, reach up and fasten it into place.

3. Fasten nails or other fasteners in the center of the nailing slot.

4. Do not force the panels up or down when fastening in position.

5. Do not drive the head of the fastener tightly against the siding nail hem. Allow 1/32 inch (about the thickness of a dime) clearance between the fastener head and the siding panel. Drive fasteners straight and level to prevent distortion and buckling of the panel.

6. Leave a minimum of 1/4 inch clearance at all openings and stops to allow for normal expansion and contraction. When installing in temperatures below 40 degrees, increase minimum clearance to 3/8 inch.

7. Do not caulk the panels where they meet the receiver of inside corners, outside corners or J-trim. Do not caulk the overlap joints.

8. Do not face-nail or staple through the siding. Vinyl siding expands and contracts with outside temperature changes. Face-nailing can result in ripples in the siding.

9. When residing, furring or removal of uneven original siding may be necessary.

10. The installation of specific products may differ in details from brand to brand. Always follow the manufacturer’s instructions, using parts specified by the manufacturer, to ensure proper installation.

Finishing Up

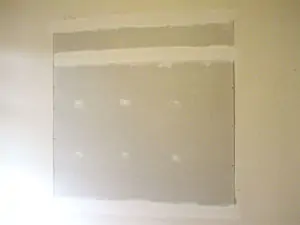

On the inside of the house, a gaping hole remains on the opposite side of the new wall. Petrucci and his crew installed insulation between the studs and covered the studs with drywall panels cut to fit the opening.

Cutting and hanging drywall is a fairly easy chore. Space the wall fasteners about 16 inches apart. 1 3/8-inch drywall screws are recommended for 1/2-inch-thick drywall. Cover the seams in mesh drywall tape.

“Finishing the drywall was one of the toughest parts of the project,” says Petrucci. “It was tough getting the new drywall to blend evenly with the rest of the wall.” Mudding drywall seams can indeed require a little finesse. Apply drywall compound over the fasteners and into the taped seams, spreading it evenly against the wall surface with a putty knife and feathering it away from the seams. Allow the compound to dry completely before sanding and applying additional coats.

Once the last coat of drywall compound had dried and been sanded, Petrucci completed the project with primer, two tones of paint and a chair rail. And voila! He had a single-window room with better insulation from cold temperatures — and a great new nursery for the newest member of the Petrucci family.