By Tom Matthews

Caulk products serve a number of functions around the home, but it all boils down to filling gaps. Whether you’re filling joints between two materials for aesthetic reasons or you’re filling gaps in your home to prevent air or water infiltration, the application of the product is usually done in the same way.

Not all caulks are created equal, however, and you should pay attention to the properties of the product you purchase. These days, caulking products are made from a wide range of materials, including silicone, acrylic, siliconized acrylics, latex, co-polymers and more.

The easiest and fastest way to achieve a nice, crisp caulk line is to stop by the hardware store, purchase the cheapest acrylic caulk on the shelf, and lay the bead. These cheap caulks are easy to shape and easy to clean up (not sticky like silicone). In practically no time you can fill that crown molding joint and take a photo of your beautiful work. And it’s a good thing you’ll have that photo to remember it by, because within a year the caulk bead will likely dry out, shrink and develop unsightly cracks.

The problem lies in the cheap caulk’s inability to stretch coupled with the the surrounding material’s tendency to expand and contract with moisture and temperature changes. The crown molding moves, the caulk doesn’t, so the bead cracks, looks ugly, and you have to re-caulk it within a year.

To avoid this, choose a better caulk product. Rather than committing to memory the various chemical names for ingredients, pay attention to the indications on the label. Look for words like “elastomeric” and “flexible” which means the bead will bend and stretch in lieu of breaking when the surrounding substrates move. The company Sashco makes a water-based caulk/sealant called Big Stretch that will twist, bend, compress and stretch more than 500 percent of original size.

“Adhesive” is another good characteristic for caulks, especially for application to substrates that are difficult to stick to. If a bead pulls away from the substrate, then the seal has failed, so adhesion is very important.

A high-quality caulk/sealant such as Lexel, which is essentially a liquid rubber, will even stick to wet surfaces.

“Waterproof” sealant is what you’ll need for exterior applications, and “Mildew-resistant” is a crucial characteristic of visible caulk used around moisture-prone areas such as showers and bathrooms.

If you plan to paint the caulk bead, then look for “paintable” on your product package, because not all sealants will hold paint. Although silicone has long been a standard sealant for exterior doors and windows due to its elastomeric properties, conventional silicone sealant will NOT accept paint, and the paint will simply bead up and bleed off the surface. “Paintable” caulks, however, will readily accept a new topcoat in your choice of color.

Another note about silicone sealant: It tends to yellow over time. So if you don’t plan on painting the sealant, then make sure it has “non-yellowing” properties to maintain the look of the bead.

And, as the old saying goes, “you get what you pay for.” Cheaper caulks are less expensive because they’re formulated with inferior ingredients that don’t offer the properties that will keep the caulk performing well and looking good over time. So if you skimp on the cheap stuff, you’ll soon be reapplying the product or else living with some ugly joints around your house—neither of which you had in mind when applying the caulk in the first place.

Pro Tips for Caulk Application

Surface Prep. To remove a grungy bead of silicone for replacement, cut through each side of the bead with a utility knife and pull it away by hand. To remove any remaining sealant, scrape it with a paint scraper held at a shallow angle. If no sealant is in place, clean the surface of any dirt, dust, grime or oil that would prevent the sealant from adhering. Scrub the surface with mineral spirits and an abrasive pad to get rid of any residue prior to applying the caulk.

Cut the Nozzle Correctly. Most pros bypass the nozzle cutter of a caulk gun in favor of using a utility knife to start a new cartridge. The razor blade slices smoothly through the plastic without clamping it. The clamping action of a caulk-gun cutter can distort the nozzle opening, which can then impede application of the product. Cut the cartridge nozzle at a 45-degree angle with an opening size of 3/8 inch. For the same reason, cut the nozzle of squeeze tubes with a utility knife while holding the crimped end of the tube vertically. Lay the bead parallel to the 45-degree nozzle.

used with a back-rod will stretch to withstand joint

movement better than any other configuration.

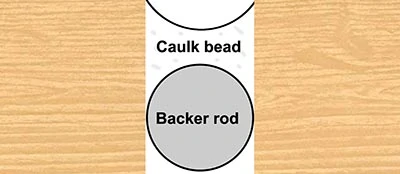

Backer Rods for Big Joints. To seal a joint larger than 1/4-in. wide, use a foam backer rod as a filler before applying the caulk. Less expensive than caulk, the rods provide a cheaper way to fill the empty space than using caulk alone. Plus, when caulk is applied over a backer rod, it forms an “hourglass” shape with two large areas of adhesion at the sides of the joint. The hourglass shape of the caulk bead stretches to withstand joint movement better than any other configuration.

For gaps larger than 1/4″, first use a foam backer-rod

to fill the space.

Caulk a Bathtub. Don’t grout a bathtub—caulk it. When caulking a bathtub, first fill the tub with water. The weight will pull the tub downward, maximizing the size of the joint. Apply a flexible, waterproof caulking along the edge of the tub in full contact with both vertical and horizontal surfaces. This prevents future stress and cracking of the caulk joint.