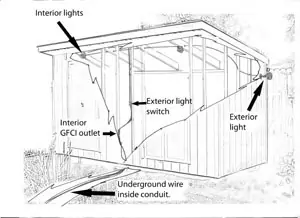

When is a shed a shed, and not a shop or a barn? Sometimes the answer to that question is a technical one and determines whether or not you need a building permit. Most of the time however, it’s up to you. Location, purpose and size of your outbuilding determine the fit and finish, but one thing I try to do if possible is get some lights in there.

Some sheds need lights. Many of us leave for work when it’s dark and get home when it’s dark during those short days and long nights of winter. So if you’re going to use a shed to store tools, toys or supplies, then you’ll be using it in the dark for much of the year.

I’ve had my share of trips to sheds with a flashlight, so when we planned a new garden shed, I started looking for the best way to get some juice to the location. An outlet on the outside of the house provided a source for power, so we dug a ditch from that location to where we would build the shed.

Check your local codes, but the basic requirements are (1) adequate gauge wire and breaker, (2) GFCI protection on the circuit, and (3) special underground wire or conduit.

You can run your wire underground in sealed PVC conduit or you can use type UF underground cable, as long as the wire is protected with conduit wherever it is exposed.

We elected to us type UF and PVC conduit. I figured the wire could use some extra protection in case I get the idea to build an alligator pit and forget that the shed wiring is there. However, the type UF cable we used was a pain in the butt for stripping the insulation to make j-box connections.

Here’s how we got it done:

Once we knew where the shed was going to be located, we dug a trench from an existing exterior junction box (j-box) to the new outbuilding.

Then we ran PVC conduit to protect and route the wire underground, leaving enough extra length for us to decide where to place the first outlet to be installed in the shed.

Extra pieces of conduit were added to protect the wire against puppy teeth between the ground and the shed floor. We then drilled a hole through the bottom plate of the shed framing and through the floor, and threaded the wire from outside into the shed.

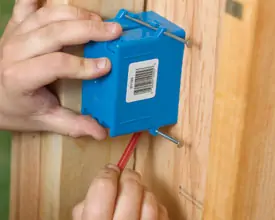

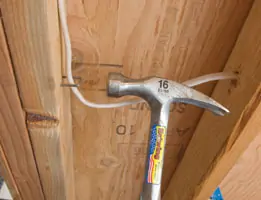

An outlet j-box about a hammer length was set off the floor. With the j-box elevation set, we attached the box to a stud using the supplied nails.

We snaked the wire through one of the openings in the j-box then secured the wire to the framing with a wire staple. Be sure to drive the staple in without damaging the insulation around the wire.

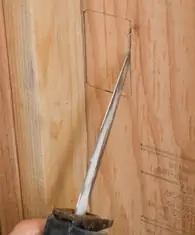

We tried several methods to strip back the outer shielding of this underground wire. The added challenge is because the outer insulation is not just a sleeve like regular romex, but fills all of the space around the individual 12-gauge wires as well. Be careful not to cut the inner insulation around the individual wires.

Wire strippers have gauge-specific notches so you can find what works for the wire you are using. Remove 1/2-inch of insulation from the wires to prepare for installing the outlet.

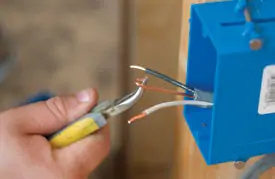

There are usually two ways of attaching wires to common household outlets: screws on the sides or holes in the back. The ground wire, however, is usually fastened only with a screw, which means you’ll need to bend a small loop for connecting it. Needle-nose pliers work well for this task.

Bending the hook clockwise helps keep it in place when you tighten the screw.

Insert the remaining wires into their proper terminal holes (white to silver and black to gold) and tighten the screws to hold them in place.

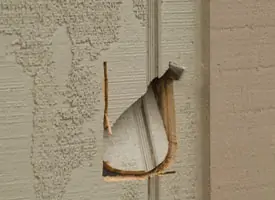

We decided to make our light switch accessible from the outside of the shed so we could turn on the lights regardless of the door we used, and so we could turn on an exterior floor light without going into the shed. We used the switch j-box as a template to mark the opening so we could cut it against the stud from inside the shed.

If you are experienced with a reciprocating saw you can make a plunge cut, but it’s usually safer to drill a hole to get started.

Cutting from the back works well because the saw teeth are cutting on the return stroke, which helps prevent tear out.

Because this j-box wasn’t really designed for this application, we pre-drilled on the stud side of the box and fastened the box to the stud with screws.

A 3/4-inch spade bit was used to drill holes through the studs to route our wire from the GFCI outlet to the light switch.

We again attached the wire to the framing using wire staples.

Next, we attached the light fixture j-boxes to the ceiling joists and ran wire from the left light to the light switch.

Then we connected the black wires and the ground to the light switch, and connected the white wires together inside the switch j-box using wire nuts.

We cut about an 8-inch section of romex and stripped the outer insulation so the individual strands could be used for pig tails to connect to the light fixture.

Three black wires are connected together at the first light j-box (feed, pigtail and the line to the next light in series). The same goes for the white wires.

Remember, the power pigtail wire (black) goes to the brass/gold terminal on the light fixture, and the neutral pigtail wire (white) goes to the silver terminal.

Once you have the wiring finished, tuck the excess into the j-box and install the fixture. A drill is handy for this, especially when working on ceiling-mounted units.

Our final light fixture in the series was an exterior flood light. After marking the j-box location on the inside, we drilled partially through with a spade bit. Drill until the tip of the bit can be seen from outside.

To prevent blow-out (splintering the siding), finish drilling the hole from the outside.

We used a jig-saw to cut as much of the circle as we could from the inside. This gave us enough of the circle to finish marking and cutting the j-box opening from the outside.

The wires on the floodlight fixture were multi-strand, so we wrapped them around the 12-gauge wire and bent the larger wire back over the multi-strands before covering the connection with a wire nut.

Remember to install the supplied weather seal gasket between the exterior fixture and the j-box.

Before connecting our new shed wiring to the house, we tested the circuit to make sure we had tripped the right breaker.

Finally, some creative conduit work allows us to use a pre-existing hole in our power source exterior j-box keeping everything properly sealed.