Wall Trim Tips from a Professional Carpenter

By Robert Robillard

One of my favorite finish carpentry activities is to make and install wainscoting. Wainscoting is a broad term referring to trim that is added to the bottom quarter of the wall.

Wainscoting helps enhance the structure and design of the room by splitting the wall into two sections and giving the eye a line to follow. When placed at the right level, wainscoting can also give height and presence to a room by elongating the look of the wall or tying in a high ceiling.

Wainscoting functions to give formality and balance to a room. It can also give a room a textural interest that ordinary, flat painted walls cannot achieve.

The term wainscoting actually refers to the application of decorative paneling that’s placed between a baseboard running along the floor and a chair rail or wainscot cap on the wall. Wainscoting has been around for centuries and is a very popular finish trim option in the New England area.

Types of Wainscoting

The type of material used for wainscoting can be wood paneling, cope and stick panels, overlapping boards or applied moldings. Wainscoting can be as elegant and formal as a raised panel, or a simple as a flat panel with a chair rail.

A chair rail is a horizontal molding attached to the wall above the wainscoting. I’ve never seen wainscoting installed without a chair rail of some sort. The height of a chair rail typically ranges from 32 to 48 inches above the floor.

Wainscoting that consists of raised, flat or recessed panels provides a simple, clean look popular in Mission style and Arts and Crafts style homes.

Beadboard wainscoting consists of vertical tongue-and-groove boards that interlock to create vertical lines, as often seen in pantries, cottages or country style homes. This look has become very popular in mudrooms, kitchens and baths.

Often times you will see vertical beadboard wainscoting measuring 42 to 72 inches high, especially in dining rooms.

Finish carpenters and designers have used wainscoting for architectural design and visual appeal since the late 1500s. Although there is no structural purpose for wainscoting, the extra feature adds contrast and design to the living space.

Wainscoting is commonly painted to match existing trim in a home; however, employing different paint colors and treatments can add character and personality to a home’s interior. For example, a raised panel wainscoting gives a room a more formal appearance. Dark stained wainscoting adds a masculine touch for a man’s room. White painted wainscoting against pastel walls becomes a youthful, feminine combination.

How the wainscoting is designed and finished makes it usable in almost any room in the house.

And then, there is faux wainscoting.

What is Faux Wainscoting?

Faux wainscoting has recently made its way into today’s homes due to its easy installation and cost savings in time and material. It’s a very affordable and interesting solution to blank walls.

Faux wainscoting basically entails attaching moldings to the wall to create the look and effect of solid wainscoting panels. Faux wainscoting can look as good as the real thing and is cost-effective when compared to solid wainscoting. Either way, both methods add instant elegance to almost any room.

The goal with installing faux wainscoting means gluing and securing molding, as well as chair rail molding, to create the look of solid wainscoting.

The moldings are mitered to create a square or rectangle, and the wall and moldings are painted one color to look like solid wainscot. It’s basically the process of using picture-frame molding to create panels.

Adding Wainscoting to a Curved Wall

Recently, a friend of mine wanted to dress up the front entryway of his home. A stairway near the door had a curved wall that was very bare and rated “blah at best” on the interior design scale.

Because of the curves, faux wainscoting was a great solution to add some instant class to this entryway and also stay within budget. New paint and wallpaper will dress it up once finished.

On this job we kept the existing baseboard trim and bought a larger version of the faux molding to use as the chair rail.

After identifying and procuring the moldings needed, we cut lauan strips to use for layout and made an acute-angle jig before setting up our laser level to mark the walls.

Materials Needed

- Carpenter’s calculator

- Solid wood molding

- Flexible molding

- 1/4″ strips of lauan ply

- Latex Adhesive caulk

- Polyurethane construction adhesive

- Wood glue

- Pneumatic finish and brad nailers, compressor

- Levels, laser level

- Miter saw

- Acute-angle Jig

- Painter’s tape

Design and Layout the Panels

For any type of wainscoting to look proper, the panels must be laid out so that each of them is the same size and equally spaced on the wall. When installing panels on more than one wall, this means that different walls may have a different size and number of panels, depending on the wall’s length.

We used a calculator to determine equal spacing of the vertical molding and panels that were pleasing to the eye of the homeowner.

Note: Generally, the bottom rail is taller than the top rail. However, on our project we chose equal spacing on all sides of the faux panels.

To calculate the layout of the panel spacing, always begin with an estimate of the panel size, then run your numbers to determine the exact panel number.

Add your stile measurement to your panel size and divide the wall’s length by your number. Remember that there is always one more stile than there are panels. This is because the corners should begin and end with a stile.

Tip: When laying out the wainscoting, look around the house for design clues. I often use the width of vertical stiles on paneled doors for my wainscot vertical panel spacing.

We purposely laid out the panels so any switches or outlets would either land on a rail (area between two vertical moldings) or inside a faux panel, taking care not to have it land too close to the molding’s edge.

Once you have your layout established, I suggest you make a full scale drawing on the wall to eliminate any confusion and to discover any layout problems.

Drawing your Layout on a Curved Wall

We needed a straight edge for drawing our panels and marking the curved wall. We used lauan plywood ripped down to 3-in. strips as a template and tracing material. It works amazingly well to measure, mark and lay out the curved wall.

Note: Lauan plywood is a cheap version of mahogany plywood and comes in a 4×8 sheet in 1/8- and 1/4-in. thicknesses. It is very flexible and perfect for curved wall applications.

We set up two laser levels both with horizontal lines and were able to mark the entire rooms top and bottom molding lines, which pinpointed the placement of the lauan we used to guide our drawing.

On this project the homeowner chose 4-in. spacing for everything. We applied this 4-in. measurement for spacing the faux panels from each other, the baseboard and chair rail.

Cut the Molding

The molding can be cut easily with standard woodworking tools, and a miter saw works best for cutting accurate angles.

Each wall will have a slightly different “panel” size based on the distance between wall corners and door openings. If the math is correct, all of the molding for a single wall can be cut at one time, which speeds production.

Fasten the Molding

Most of these moldings will not land on a wall stud, so we needed to glue them to the wall and use finish nails to hold the molding in place while the glue dried. We used latex adhesive caulking and polyurethane adhesive for gluing the molding to the wall.

Six-penny finish nails driven at opposing angles into the dry-wall were installed to cinch the molding tight to the wall while the adhesive set. Molding frame corners were mitered and nailed to each other conventionally with finish or brad nails.

The chair rail molding was installed the same way, but because it spans across wall framing we could fasten them to the studs with finish nails. On a curved wall, I recommend using the adhesive caulking as well.

Flexible Molding to the Rescue

Installing molding to a curved wall meant using Duraflex moldings from ResinArt. These flexible moldings are a simple and economic alternative to curved applications where wood moldings won’t work.

It’s important to pick a flexible molding that also matches the solid molding. We chose an astragal style molding for this project. The moldings come in a box, in 10-ft. sections. When I compared the flexible molding to the wood molding they were nearly identical.

The flexible molding has the appearance of real wood and installs with standard woodworking equipment. It cuts, sands, shapes and finishes like wood. When cutting these flexible moldings, take care to provide additional support. If not, the molding flops and bends, which can affect the quality of the miter cut.

Since the flexible molding costs three times that of the wood, I used the wood on all of the vertical molding pieces on the curved wall.

I used polyurethane construction adhesive to glue the flexible moldings to the walls, and adhesive latex caulk for the wood. Both types of moldings were also secured with a pneumatic 16-gauge finish nailer.

Tip: Drive the finish nails at different opposing angles for better holding power. The angle holds the drywall or plaster better than installing the nail straight into the wall.

Flexible molding can also be used on half-round windows, elliptical windows, arches, arcs, radius drywall corners, round columns and more.

Paint and Caulk

After installing the moldings, apply caulking to all the seams.

If you want to make the faux wainscoting look like solid wainscoting, then paint the wall from the chair rail down a color that differs from the upper portion of the wall. Some folks also paint the panel interiors different colors for a more dramatic look.

Editor’s Note: Robert Robillard is editor of A Concord Carpenter and principal of a full service carpentry and remodeling business located in Concord, Massachusetts. Visit www.aconcordcarpenter.com.

Side Note 1

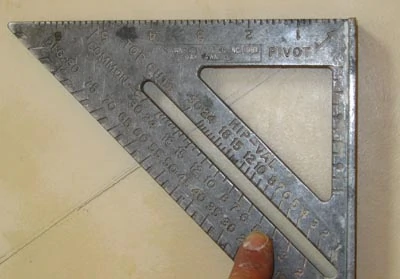

Acute-Angle Jig

There are many times when I need cut trim or molding at an angle greater than my miter saw is designed for. Most miter saws cut to 45 degrees or slightly larger, usually 50 degrees.

But what if you need to cut 55 degrees or greater? One very dangerous way is to hold the piece to be cut perpendicular to the saw’s fence and freehand this cut. I do not recommend cutting trim this way.

A safer solution is to make an acute-angle cutting jig and keep it with your saw.

I made this one out of scrap wood, and it creates a new fence perpendicular to the saw’s fence, which gives you greater control when cutting the sharp angle.

I arbitrarily chose 12-by-12 inches for the jig. I cut a 12-in. square of

3/4-in. plywood and then cut it diagonally to make a brace for the jig.

Scrap 5/4 trim makes up the edges. I chose 5/4 sides because the raised edges give me plenty of space to clamp or screw the jig. I screwed the parts together at 90 degrees, then I clamped the jig to my saw fence.

Tip: Have scrap material on hand to practice using this jig and to help determine the correct miters.

Side Note 2

Custom Manufactured Spiral Stairs

Side Note 3

Wainscoting Resources

WainscotingAmerica.com is a great source for ordering wainscoting panels online in minutes. The company has advanced manufacturing techniques that allow it to make custom complex panels very efficiently, delivering premium wainscoting at affordable prices that ship in 5 business days. The company offers a one-piece MDF custom wainscoting panel up to 9 feet with no seams. The innovative online design system allows DIY customers to design and order complex custom panels without the need for an expensive carpenter. The design tool will automatically try to determine the optimal number of inner panels for a given panel size. It uses the golden ratio of 1.618, which is the height of the panel to the width of the inner panel. There are books written about the golden ratio, how it is found in nature and that the Egyptians and Greeks used it in their ancient architecture. Most of the literature on the golden ratio states that rectangles with this ratio are more appealing to the human eye. However, you can modify the design as you see fit. Visit www.WainscotingAmerica.com.

AmericanBeadboard.com is an online source for high-demand beadboard wainscoting. The reasonably priced beadboard panels are cut from 5/8-in. thick premium MDF and will ship in 3 to 4 business days. A 36-in. tall 8-ft. kit starts at just $119. Visit www.AmericanBeadboard.com.

Other Wainscoting Articles