Be careful what you specify, not all treatments are the same

Exterior wood trim adds natural dimension and architectural interest to any home. The good news: exterior treated trim product awareness by builders is raising the bar to force manufacturers to provide products that will last. But, with so many warranties and manufacturers’ claims to digest, separating technical fact from marketing hype is a challenge for industry professionals. This article explains what true preservative treated wood is and how it protects users against future liability claims, and how protective coating treated wood gives minimal protection against rot and decay.

Wood Preservation vs. Protective Coatings

Wood preservation, as defined by the American Wood Protection Association, the industry’s standards developer:

| “The technology of reducing and/or preventing the deterioration and destruction of wood by living organisms, particularly fungi, insects, and marine borers…through the application of wood preservatives.” | |

This is a critical primary first step, before any discussion of protective coatings used to seal off the adverse effects of weather. ArmorCoat XT® is treated with Wolman® AG, which is qualified by the AWPA as an approved preservative with strict application performance standards. These processes require weekly Quality Assurance (QA) sampling and monitoring to ensure proper wood penetration and retention levels of the preservative.

Protective coatings such as those featured in RealTrim Treated® for example, are defined as film forming primers and paints applied to the wood surface as a sealant. Many protective coatings contain mold and mildew inhibitors, but these are not designed for decay causing fungi. These primer additives, commonly known as Iodopropynyl butylcarbamate (IPBC), are registered by the EPA, and the allowable usage is tightly regulated. Many primers (such as those used by ArmorCoat XT) contain the maximum amount allowed by the EPA. The same can be said for the efficacy of borates or PTI* when mixed with protective coating sealants. These protective coating with additives are nothing more than sealants or barriers to the wood substrate. Break the seal and the wood beneath is now subject to structural decay and insect infestation.

Can Treated Primer Equate to Treated Wood?

Suggesting that a film forming protective coating ‘sealant’ is comparable to a wood preservative is misleading. Exterior wood trim producers that believe in, and stand behind true preservative treatments use a true two-step preservative treatment process to ensure the wood substrate is fully treated before adding the film forming protective coating.

“If it was possible to simply add some version of ‘preservative’, approved, certified or not, to the primer, and retain a non-prorated warranty, we would have done it a long time ago,” said Roger Roatch -Belco Forest products VP of Sales and Business Development. “The science and physics don’t back up any claims that stretch so far as to equate treated primers with preservative treated wood.”

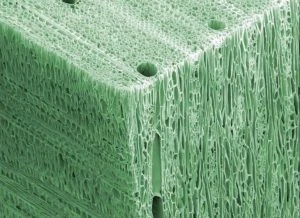

In order to achieve a level of protection required by agencies like AWPA, the appropriate chemicals and processes must be regulated and followed, and only a two-step method can assure preservation of the wood cells. This process is then certified by an agency like AWPA to verify the efficacy of the process with industry ASTM (American Society for Testing and Materials) standard testing methods.

Primers loaded with solids for specific purposes, make it virtually impossible for any effective attempt to separate additives from the primer and have any chance at penetrating the wood cells. Further, manufacturing requirements to accommodate production flow, eliminate the absorption/diffusion reaction because of the oven dry process. The minute wet primers are introduced to oven curing, any volitile liquid (solvent or water based) immediately flashes off, leaving only solids to cure. This eliminates the physical ability for either carrier to take any preservative treatment below the surface of the wood face.

Manufacturing Process and Cost

The certified two-step process is truly the only way to assure preservation and decay resistance of wood, wood fiber, and into the structural cell walls. This process definitely comes at a cost, but compared with the added value and assurances, it is negligable to the end user and depends largely on the efficiency of the manufacturer’s process. There is no simple shortcut to proper wood treatment and it requires special equipment at the milling plant, QA plant personnel to ensure process controls are monitored and finally, lab testing to ensure true efficacy of the preservative treatment process. This cannot be achieved by circumventing systems/processes developed by the treatment chemical producers and verified by AWPA, through rigid ASTM standardized performance testing. From a manufacturing perspective, it is essential to manage these processes by producing the product from start to finish in-house. This ensures consistent QA during the entire process, that third party contracted fabrication can’t offer.

What’s Behind a Warranty?

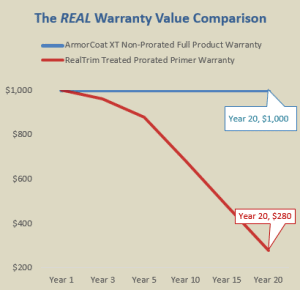

If a product meets or exceeds all applicable industry standards for preservative treated wood and controls are in place to ensure system efficacy, those companies producing said product would be fully transparent and lead with the technology to give end users the assurances they deserve. Untreated, exterior primed and painted wood, exposed to constant wetting and drying cycles, can only be expected to last 7-13 years, and it is irresponsible for professionals in the construction supply industry to offer something so unreliable and risk-prone to homeowners. The reason a 20 year “non-prorated” warranty exists, is that both the producer and chemical provider can rely on the science behind the AWPA/ASTM tested systems. Otherwise, a prorated warranty is hardly worth the paper it’s

printed on.

- Based on $1000 original purchase price for trim products

- Average lifespan of untreated SPF trim is between 7-13 years

Chart based on printed warranty terms for ArmorCoat XT and RealTrim Treated.

* Propiconazole-Tebuconazole-Imidacloprid (PTI)

Literature Cited

- Forest Products Laboratory. 1999;2010. FPL-GTR-113/190, Wood Handbook – Wood as an Engineered Material

- AWPA 2017. Book of Standards. Birmingham, AL, American Wood Protection Association