Back to my ongoing stair remodel…

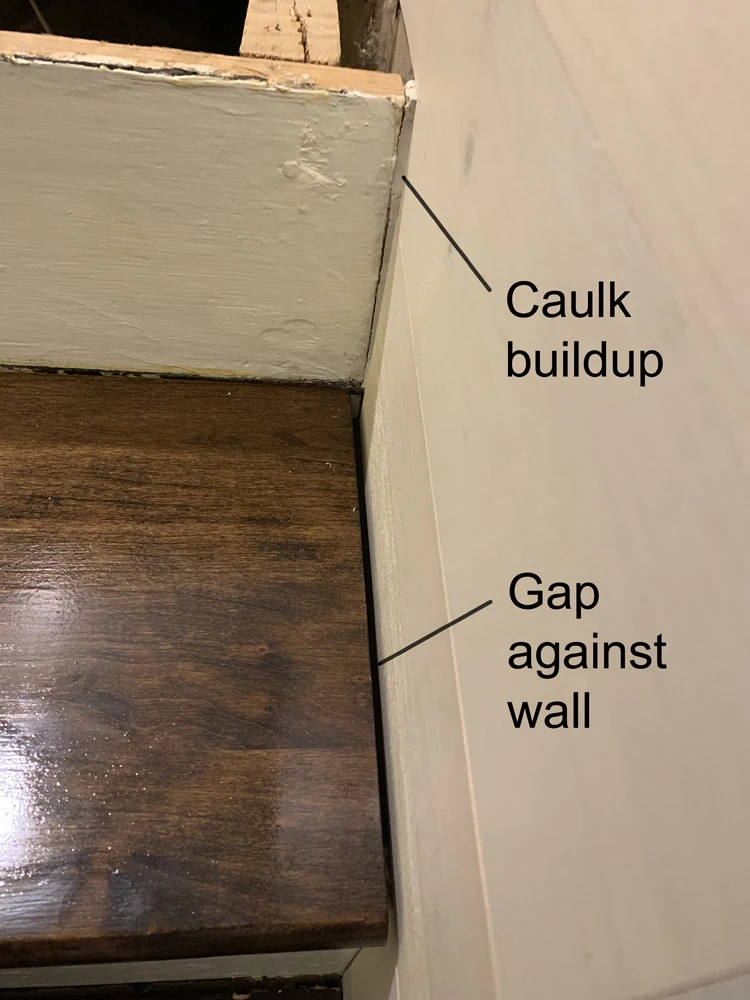

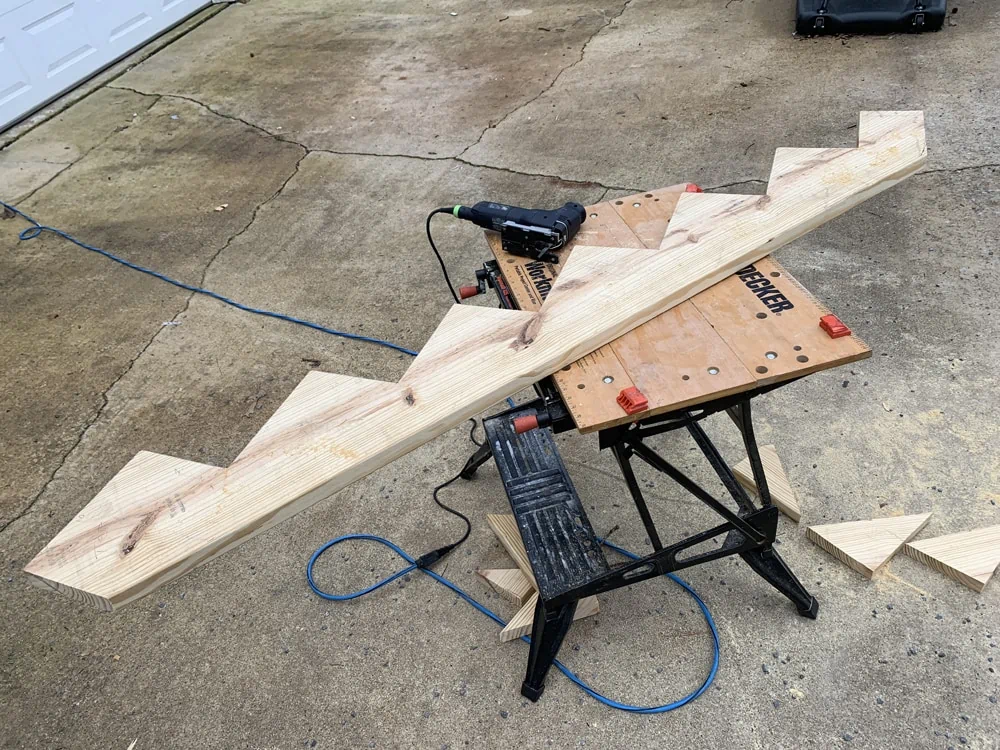

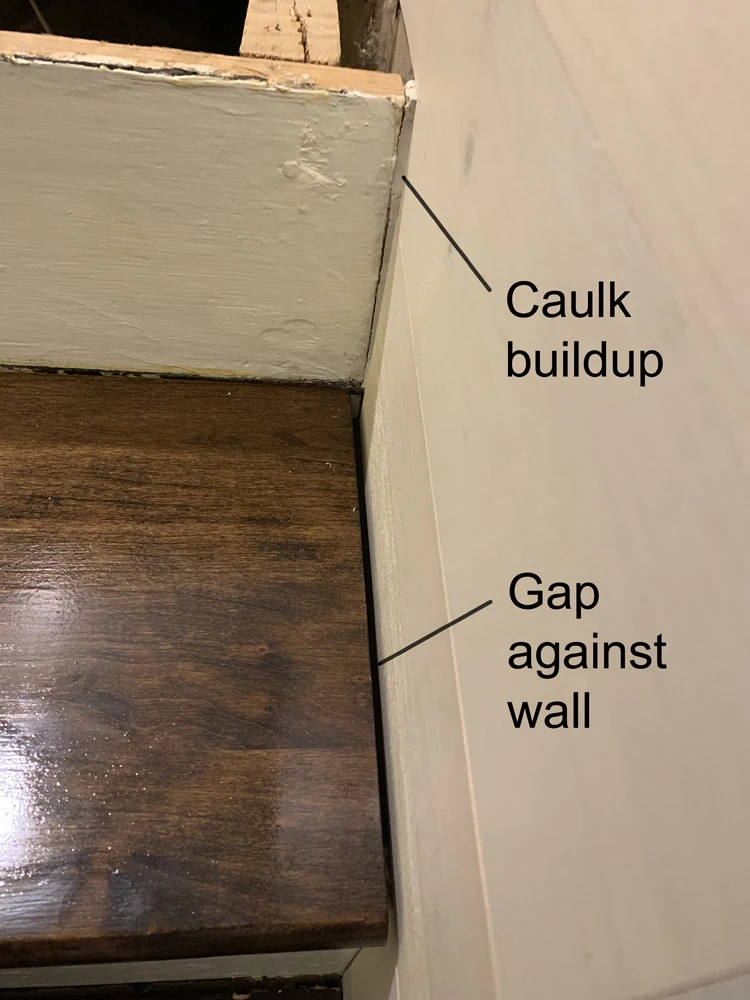

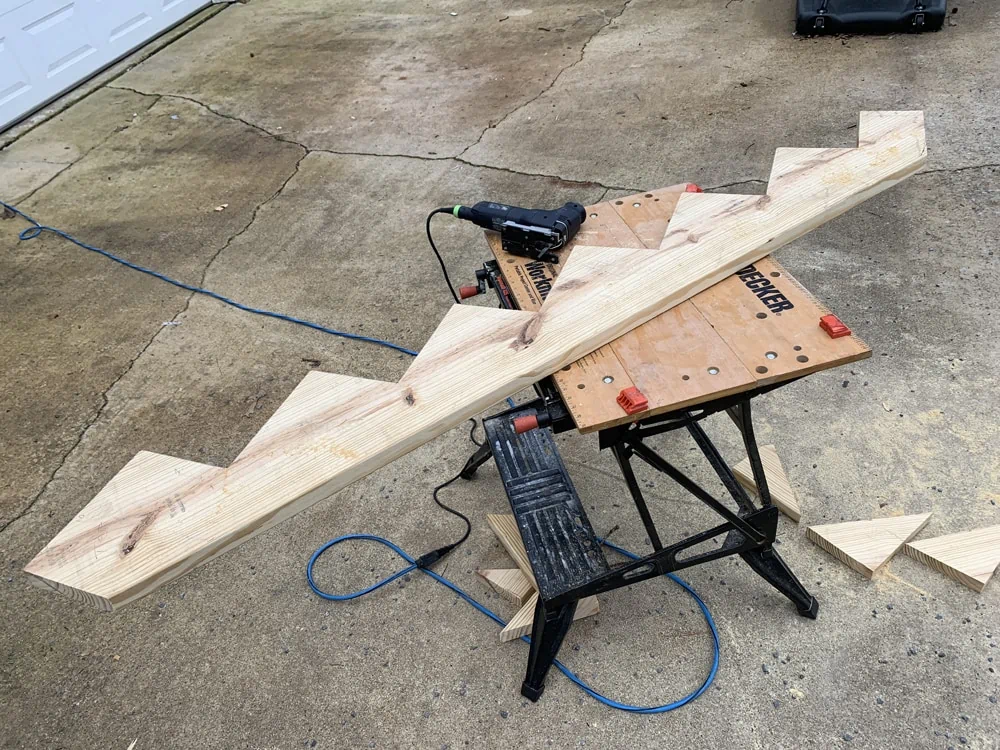

A funny thing happened on the way to installing the remaining treads: Everything went haywire. I’ll try to sum it up as succinctly as possible:

Home » Newest Articles » Stair Stringer Installation

Back to my ongoing stair remodel…

A funny thing happened on the way to installing the remaining treads: Everything went haywire. I’ll try to sum it up as succinctly as possible:

Industry experts predict that thermally modified wood will become a standard choice for high-quality exterior applications, reshaping the decking (and siding) market landscape. As an industry-transforming option, it caters to the needs of homeowners, builders, and designers seeking high-performance, low maintenance, and eco-friendly alternatives for exterior applications. Recognizing this market evolution, DeckWise® has extensively studied […]

Read More >>