Over the last several years impact drivers have launched to the top of the must-have tool list for DIY’ers and professionals alike. An impact driver uses an internal anvil to deliver much higher rotational torque than conventional drill/drivers. When the power needed to drive the fastener exceeds the torque of the tool’s rotational force, a drive gear with two matching lugs strikes the anvil to nudge the bit along. The impact action drives fasteners very quickly, and little pressure is needed on the head of the tool. But this extra force brings with it extra wear and tear on standard driver bits.

In response Makita’s new line of Impact GOLD fastening accessories are designed exclusively for high-torque impact drivers. The product line begins with high-quality steel engineered to help withstand the increased impact energy of these demanding applications. Makita’s Xtreme Torsion Technology allows the torsion section of the bit to flex under load and take the pressure off the tip. This helps the insert bit withstand high-torque fastening, retain its shape and “fitment.” According to Makita engineers, the Impact GOLD bits last up to 10-times longer than standard bits – and up to 15-times longer when used with an Impact GOLD Torsion Insert Bit Holder.

Bit Holders

Impact GOLD offers two bit holders, both with Xtreme Torsion Technology. In addition to the Torsion Bit Holder, the Ultra-Magnetic Torsion Bit Holder features a rare earth Neodymium magnet with twice the magnetic strength of a standard magnet to enable one-handed fastening – ideal for overhead applications or work in tight spaces.

Insert Bits

In fastening, accurate “fitment” is when the driver bit fully engages the screw with equal contact on all surfaces, leaving no gaps and resulting in a precision fit that prevents “cam-out” (stripping the head of the fastener). Check the bit “fitment” by pressing the bit into the screw head and measuring the side-to-side movement. The more movement, the worse the fitment. Another indicator of poor fitment is “wobble” or “slop” when in use. This off-center alignment and uneven fitment causes those frustrating cam-outs. Impact GOLD insert bits are designed to eliminate this problem.

Nutsetters

Although standard magnetic nutsetters can effectively hold fasteners in place, the magnet also captures metal debris, an inevitable byproduct from driving screws into metal materials. Eventually the magnetic nutsetter becomes so jammed with metal debris that becomes useless. To address this issue, the new Impact GOLD No Debris Grip-It Nutsetters utilize a non-magnetic snap-ring that holds the fastener securely in place without collecting the unwanted debris. The Impact Gold Nutsetters are currently available in sizes 5/16″, 3/8″ and 7/16″.

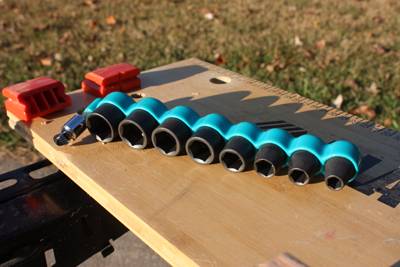

Socket Adapters and Socket Set

With the new Impact GOLD socket adapter, you can use your impact driver as an impact wrench. The new 3/8” square-drive sockets are machined from heat-treated alloy steel for high-torque applications and feature a black oxide finish for longer socket life. The 9-piece socket set includes a 3/8” Square Drive Socket Adapter, which tilts up to 15 degrees for work in tight areas.

Overall, the Impact GOLD is a fine line of products to withstand the rigors of professional high-torque fastening, day in and day out. Find out more at www.makitatools.com.

–M. Weber