Insulating the Attic for Energy Efficiency

By Clint C. Thomas

As we balanced on top of ceiling rafters, my son Sterling asked me, “How does insulation help to keep our house warm?” I explained that it was the same as adding a blanket to a bed in the winter or putting on a jacket when it is cold. Insulation is of critical importance to a home by providing a barrier between the climate controlled temperature inside the house and the often brutal outdoor temperatures.

Since heat rises, one of the most critical areas is the attic. Without attic insulation, or sufficient attic insulation, a great deal of our artificially produced heat escapes by simply rising through the drywall ceiling into the attic space.

In addition, attic insulation also provides protection from the summer’s heat, which helps to reduce our monthly cooling bill.

Exterior wall insulation is the second most important area to insulate. Some homeowners, especially in cold climates, will also insulate in their crawl spaces between the floor joists. When it comes to insulation, another important area to consider is the windows. Even with the best insulation that is available, a lot of air transmission can occur around widows if they are not sealed properly, deteriorate from old age or because they are not of the double-pane insulated variety.

Insulation comes in many different types. Originally, homes did not contain insulation, which is why our grandparents would often stick old newspapers inside their walls. Paper, in fact, is one of the best insulating materials available, but it comes with two major drawbacks. One is that it is highly flammable. Manufacturers attempted to resolve this issue by adding boric acid to shredded newspaper, both as a fire retardant and also as a poison for roaches. The other drawback to paper is that it breaks down and loses its insulating properties when exposed to moisture.

A modern form of paper insulation is known as cellulose. The materials that comprise cellulosic insulation include newspaper, cardboard, straw and even sawdust. Cellulose is making a comeback because it is more environmentally friendly than fiberglass insulation. Cellulose insulation is made of loose fibers and is sold in vacuum-sealed packages. It is simply broken up and poured into a machine that blows the insulation through a long hose. The do-it-yourselfer then directs the hose throughout the attic and blows in the desired amount of insulation. Blown-in insulation has the added benefit of allowing the installer to control the volume of insulation that is being installed, which means controlling the R factor by applying additional insulation in needed areas.

Currently, fiberglass insulation has replaced paper as the industry standard. It is fire retardant and comes in either rolls or convenient pre-cut bats. It is available in two different varieties, faced and un-faced. Faced, simply means that the insulation has a paper covering on one side. However, don’t be misled by the word paper. There is paper on the outer layer, but a plastic sheet is bonded to the reverse side of the paper to form a moisture barrier.

Un-faced insulation is fiberglass insulation without the vapor barrier. A vapor barrier is necessary since human beings, who are comprised of mostly water, produce a lot of moisture through normal biological functions. Anyone who has ever slept inside a nylon tent can remember how much condensation collects overnight inside a poorly vented tent. In addition to our lungs expelling moisture every time we breathe, consider all of the other activities that we engage in that produce moisture, such as bathing and cooking.

In addition to fiberglass, insulation is also available as cellulose, rock-wool, and Spray Polyurethane Foam, commonly called spray foam or SPF.

Spray foam is a spray-applied insulating foam plastic that is installed as a liquid and then expands many times its original size. As home insulation, the concept is similar to living inside a sealed Styrofoam cooler. SPF can provide high levels of R-value, while providing air barriers and moisture control in buildings. For roofing, SPF insulates and eliminates thermal bridging through fasteners or gaps in decking. (However, once foam insulation hardens inside walls or ceiling joists it encases all of the electrical and plumbing lines inside of the fill-space in a solidified mass of hard foam. This can make future repairs or remodeling work extremely difficult.)

Spray foam is available in two versions; low-density/open-cell SPF and medium-density/closed-cell SPF. The low-density version expands about 100-150 times its original liquid volume to form a semi-rigid/flexible, non-structural SPF insulation with an R-value around 3.5 per inch.

Medium-density/closed-cell SPF used in interior applications refers to spray foam that weighs between 1.5 to 2 lbs. per cu. ft. when fully cured. It expands about 35 to 50 times its original volume to form a rigid, structural SPF insulation with an aged R-value up to 6.5 per inch.

The down side to spray foam insulation is that application generally requires specialized training and equipment. Although a few manufacturers offer DIY kits for small projects, SPF is usually applied by a professional.

DIY Insulation

For DIY installation, batts and rolled insulation can be laid by hand. Blown-in fiberglass, rock wool and cellulose can be applied by almost any homeowner using a machine that most box-stores provide free of charge.

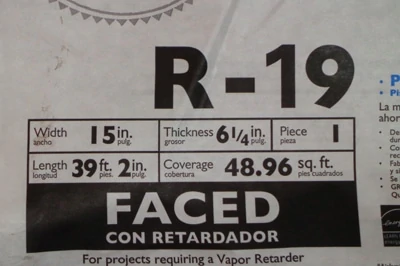

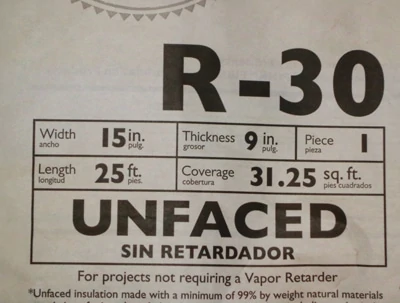

Insulation is rated by its R factor, which helps to determine the amount to install. The higher the R number, the greater the insulating properties. For example, R-30 fiberglass insulation is approximately 9 inches thick and has higher insulating properties than R-19, which is 6-1/4-in. thick. A 4-in. 2×4 wall cavity can be fitted with traditional R-13 fiberglass insulation, or the same space can be filled within injected foam that will have a value of R-26 (with an R factor of 6.5 per sq. in.).

Insulating a house is much like dressing for the cold weather. A couple of different layers will keep a person warmer than one big single layer, especially in one’s attic. Normally, R-13 or R-19 insulation is installed between the ceiling joists in the direction of the joists and then another layer of insulation, usually R-30, is applied perpendicular to the initial layer on top of the first.

The amount of insulation needed for one’s attic will depend upon the area of the country that a person lives in. Obviously, colder climates require more insulation than warmer climates. However, generally speaking, the R value of attic insulation should fall somewhere between R-30 and R-60, at a minimum.

As previously mentioned, insulation can be faced or un-faced. The layer of insulation nearest to the interior of the home should contain a vapor barrier and should be installed with the vapor barrier facing the home’s living space. In attic spaces, an additional layer of un-faced insulation, usually R-30, can be installed on top of the insulation that is between the ceiling joists for an added layer of protection. In really cold climates, a third layer of insulation, either un-faced R-30 or blown-in cellulose can be installed on top of the first two layers. Some insulation contractors recommend blowing in cellulose insulation directly on top of the first layer of insulation instead of using roll or bat insulation for the second layer. Blown-in cellulose will block out more of the unwanted air flow that causes so much of our home’s temperature loss and also fills in oddly shaped or hard-to-access cavities more easily.

In my home the original R-19 insulation had been improperly installed because the vapor barrier was not facing the living space but was facing the attic space. Therefore, my first step was to turn over all of the insulation in my attic, which had the added benefit of fluffing some of it up, much like shaking a goose-down blanket. My son and I then added additional R-19 in the spaces that did not have any insulation at all. We then added a layer of un-faced R-30 on top of the first layer and perpendicular to it.

Fiberglass insulation is easily cut with either a sharp pair of scissors or by pressing it completely flat against a hard surface and cutting through it with a utility knife. Rock wool insulation is best cut with a drywall saw, or even an electric carving knife that your father may have used on the Thanksgiving turkey.

Be sure to always wear long pants, long sleeves and gloves when handling insulation because the fiberglass irritates the skin, making most people itch. Some people like to wear a paper dust mask or respirator if they have allergy problems to keep from inhaling so many of the fiberglass particles.

The installation of additional attic insulation is a simple project that any homeowner can do over a single weekend, and will have a very real fiscal impact on their checkbook. In addition to saving money, attic insulation also saves our environment by reducing the amount of fossil fuels that we consume.