Shake it Up

By Matt Weber

Weather protection starts at the top, and a roof is not only a home’s first line of defense but also a major component of its outdoor décor. The modern Victorian house shown in this article was badly in need of a new roof, so the homeowner turned to DaVinci Roofscapes. DaVinci’s Bellaforte Shake synthetic roofing is engineered with the look of natural wood shake, but its polymer construction and innovative design make it substantially more durable and easier to install.

“We took impressions of real cedar and used our proprietary technology to transfer those extremely detailed impressions to our molds for this product,” says Mark Hansen, vice president of sales for DaVinci Roofscapes. “The final results are amazingly accurate.”

Price is another advantage for homeowners who want a high-quality roof with lasting value. Pricing for Bellaforté Shake compares to real cedar, high-end asphalt or steel roofing, but the polymer tiles offer an enhanced lifespan, insect and fire resistance, along with low maintenance and the ability to withstand severe weather conditions. Plus, the product is backed by the DaVinci 50-year limited warranty.

A full roof tear-off and replacement is a team effort, so although this not a DIY project, a smart homeowner will want to familiarize themselves with the process to make sure the job’s done right. Here’s how the Bellaforte Shake is installed.

Old Roof Removal

Tearing off the old roof is a big project, requiring an on-site dumpster and tarps to cover the surrounding ground to collect the debris. Tearing off a roof can be difficult and tiring, and workers on the roof should always be tethered to a fall-restraint harness. Shingle removers are long-handled tools the workers use to pull nails and scrape and pry off old roofing. The old shingles and paper are removed down to the bare roof sheathing. Any exposed rot or damaged sheathing must be removed and replaced before laying new underlayment.

A responsible contractor will have a worker canvas the surrounding ground with a magnetic broom to collect all the old roofing nails, so they don’t end up in someone’s heel.

Underlayment

With solid, smooth, code-com-pliant roof sheathing in place, a metal drip edge can then be installed along all eaves. The drip edge can be made from copper, aluminum or coated steel.

The next step is installation of a self-adhered membrane. The workers on this project applied Ice & Water Shield along all roof edges, gable ends, against walls, in the valleys and around projections such as vent pipes.

Roof underlayment requirements depend on whether the home’s local code requires a Class A or Class C fire-rated system.

This project required a minimum 30-lb. felt (that meets ASTM D 226 Type II standard) or a synthetic underlayment over the entire roof. Contractor Jim Butters uses Titanium UDL-25 plus Synthetic Roofing Underlayment. The Titanium underlayment is 8 times lighter and 20 times stronger than 30-lb. felt, and its synthetic construction is impervious to mold growth. For the safety of the installers it also has a “diamond plate” slip-resistant coating.

Courses of the underlayment are installed along the roof line, with the upper rows overlapping the lower to shed water. The roofers nail the underlayment using hammers equipped with metal tips for easy fastener replacement and increased speed.

Begin Installation

The Bellaforte shakes are installed with copper, stainless steel or hot-dipped galvanized roofing nails. (Ring-shank nails should be used in high wind areas.) The nails should be long enough to penetrate through the roof deck and exceed it by 3/16 inch. In most cases, 1-1/2-in. nails will work.

The first course is appropriately called the starter course, and with Bellaforte Shake this consists of specially made narrow tiles that line the eaves. To keep the starter row even the installers snapped a chalk line 3 inches above the bottom edge of the roof so the tiles achieve a 1-in. overhang. The starter course must be exactly straight or the subsequent courses of tile will be misaligned. The tiles should be spaced 3/8- to 1/2-in apart to allow for expansion.

Field Tiles

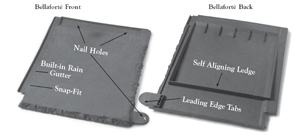

The field tiles must be laid from left to right. The first tile should seat directly on the starter tile. The field tiles are engineered with a “stop” or ledge on the bottom that rests directly on the top of the starter. This makes placement and alignment extremely easy once the starter course is in place. The tile is positioned as far left as possible. It should then be nailed on the tab first and then on the top left hand corner.

Once the first full shake tile is in place, a partial shake tile with a minimum 3-in. removed from the left side of a field tile should be placed on top of it to start the second course. This partial tile offsets the joints between tiles from row to row to ensure proper drainage.

Installation should continue so that the gutter of this next tile is placed under right side of first tile and is sitting on the ledge of the starter tile below. The tile should lock in place when pulled down or to the right. The tab should then be nailed, the top left corner should be nailed, and the top right corner of the first tile should be nailed. The installation continues in this manner, installing several courses in a stair-step pattern. Once the installers get the pattern down, the self-aligning tiles help speed up the installation considerably.

The outside edge of the tiles will be covered by tile of a different profile—a rake tile on the gable ends, or a hip and ridge tile on a hip—so precise cutting isn’t necessary. The roofers on this project cut the tiles with utility knives and a handheld circular saw.

Flashing

As with any roofing project, careful flashing is critical to prevent water penetration. Flashing should be used in all areas in which the roof intersects a vertical wall, dormer, chimney, skylight or any other protrusions. The use of copper, a minimum 28 gauge clad steel or a minimum .019 aluminum can be used.

With most of the old flashing still in decent condition, contractor Jim Butters left the old material in place and installed additional step-flashing where needed as a belt-and-suspenders approach to protection. At the wall abutments, step flashing is installed under each transitional tile and held in place by the nail that each tile receives at the top. A transition tile is a tile without the alignment ledge on the back, and these can be fabricated in the field by cutting off the back ledge with a knife or planer.

Butters installs his valley flashings as a “closed” valley. For a closed valley, “W” valley metal should be used. The center diverter should be a minimum 1-1/2 inch. Strips of 18-in. self-adhered membrane should be placed on top of the valley metal, an inch away from the center diverter, and should extend past the outside edge of the valley.

Final Tiles

An 18-in. strip of self-adhered membrane should be run vertically on top of the underlayment on gable ends. The field tiles placed on the gable end can be nailed anywhere that they will be covered by the rake tile. Rake tiles are L-shaped tiles that give the rake a finished appearance. The first tile is aligned with the first Bellaforte course and the succeeding tiles overlap each other. Rake tiles can be installed with two screws into the gable wall or fascia.

For hip roofs, a piece of flashing should be installed along the bottom 6 inches of the hip to protect the area under the seam formed by the cut field tiles. The cut tiles are butted together to form the bottom piece of hip and ridge. Once these two tiles are in place, a full hip and ridge tile is installed and pulled down so the outside corners just reach the bottom of the roof. The tiles then overlap as they proceed up the roof.

New Roof

The end result is a striking improvement. The champagne color selected by the homeowner nicely complements the outdoor décor, and the neighbors were paying their compliments before the roof was even completely installed. The Bellaforte Shake turned out to be a great aesthetic improvement, a solid investment in value and a reliable protective barrier from the natural elements.

Side Note

Perma-Boot

For this roof project, the EHT staff used the new Perma-Boot, a gasket-less, two-piece pipe boot repair system designed to permanently repair the most common type of roof leak—the leak around the vent pipes that penetrate your roof. The Perma-Boot slides right over your existing roof vent boot. Installation takes just a few minutes, and no tools are required. It’s designed for all standard roof pitches—3/12 to 12/12—and is guaranteed to be leak-free for the life of your shingles.