By Matt Weber

From cutting access to framing and installation.

I recently built a nice, big deck at the rear of our project house, but there wasn’t a door to access it from inside. I decided to install the door in the kitchen at the corner of the house, since the only other two options were the master bedroom or a bathroom. The kitchen posed problems of its own, with a huge set of oak cabinets leaving us only about 8 feet of wall space with which to work. The project was definitely a challenge, but I managed to support the ceiling, cut through the wall, reframe the wall and install the door. Here’s how it went.

Solid Support

Any time you’re cutting the studs out of a load-bearing wall, you must construct a temporary brace wall to support the overhead load. If you’re dealing with a multistory structure, I’d suggest consulting a structural engineer about how to support a heavy load. In this case I was working on the top floor with only the roof overhead, which is easily supported by the bracing techniques shown here. To build this, I first marked the proposed location of the door on the wall, and then marked the location of the ceiling joists. Make sure the brace wall runs perpendicular to the ceiling framing, otherwise you’re just holding up drywall.

I then installed a top and bottom floor plate, each made of 2-by-10’s. Protect the flooring and finished ceiling by placing a few sheets of corrugated cardboard between the plates. Extend the brace wall so the top plate extends a few feet beyond each side of the proposed door location so the overhead framing is completely supported when you cut through the existing wall. Build it about 3 feet out from the wall you’re about to penetrate to allow room to work.

It’s nice to have an assistant hold the top and bottom plates while you install the temporary studs to support the ceiling, but I didn’t have that luxury. Instead, I used a T-Jak, which is a threaded, telescoping cabinet jack that works great for all sorts of overhead installations when you need a third hand. Beginning in the center, locate each 2-by-4 stud beneath the marks for the ceiling joists so you’re transferring the weight directly to the vertical support.

When installing the studs, don’t bang them with a hammer to wedge them in place—doing so risks damaging the floor and ceiling. Instead, “snug” them between the plates, using shims if necessary. To make sure they stay in place, I fasten them temporarily by toe-screwing the studs into each plate once they’re plumb.

Finally, I finish up the brace wall with a couple of 2-by-4 cross-braces fastened with two screws each to the edge of the 2-by-4 studs. I positioned the cross-braces in an “A” shape to allow some headroom to walk through when working.

Tear Down that Wall

As long as you’ve got a brace wall in place, you might as well take advantage of this convenient frame on which to hang plastic sheeting. The homeowner will appreciate this dust barrier when you cut through the wall and kick up all sorts of airborne debris.

These days, many electronic stud finders offer the multi-functionality to detect pipes and electrical lines inside a wall. Use one if you’ve got it; otherwise proceed cautiously as you open the wall so as not to cut through such obstructions. This wall had no plumbing but did have an electrical outlet that was wired through the floor plate.

One extremely handy tool for opening the wall in an orderly fashion is a flush-cut saw. In my case, I used a Rotozip with a flush-cut attachment, which I highly recommend for this type if work. I slightly modified the flush-cut attachment by duct taping a wood shim onto the cutting guide, which gave me the exact depth-of-cut I needed to slice the drywall without |penetrating the framing—or anything else—on the other side. I then used a hammer to open the wallboard even further, pulling it away from the nails that held it on the studs, and then prying up the nails. Drywall can be a dusty mess to demolish, so remove it in as orderly a fashion as possible so you’re dealing with large panels rather than tiny chunks.

Next, remove the insulation. Fiberglass can irritate the eyes and skin, so wear safety protection and dispose of the old batts in plastic bags.

At this point I ran into an unexpected obstacle: a 1-by-4 cross-brace supporting the corner of the house framing due to a lack of structural sheathing. The sheathing panels were an old fiberboard material used primarily as an insulator, and it doesn’t have the shear strength of today’s stronger, engineered wood sheathing. So, I had to re-frame the wall using an atypical method to accommodate the lack of structural sheathing, throwing a wrench into the standard framing procedure I was hoping to detail in this article.

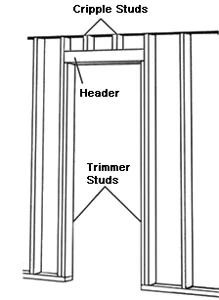

There are two important things to point out. First, see the diagram above for the details on framing a standard door opening. You can probably expect to build according to that sketch, rather than my method that employed a monster 4-by-12 header, some extra doubled studs and metal strapping to frame this door. Second, I do not necessarily advocate framing your door using the method shown in the photos, in case you encounter a similar problem with your project. As always, consult your local building inspector for an approved method, as requirements for shear walls and general construction will vary among localities, based on everything from high-wind exposure and seismic concerns to simple politics. Do as your inspector says, not as I do.

That being said, the methods for cutting through the wall and installing the door will remain the same among standard pre-hung door installations.

Framing the Door

After cutting out the cross-brace with the Rotozip, I cut the existing studs out of the house wall by using a recip saw to slice through the nails at the top and bottom of each stud (start at the top). Refer to your door for the recommended rough opening size—mine was 34 inches wide, 82 inches high. When reframing the wall, you should double the studs that frame the door. The two inner studs, called trimmer studs, should be cut to support the door header from beneath. The header is designed to assume the load that would have been supported by the studs that you’re removing; it transfers the weight to the trimmers. Unlike the monster 12-by beam I used as a header, most single entryways can get by with a 4-by-4 header. (For example, a 4-by-4 No. 2 Douglas fir header achieves a maximum span of 48 inches, which is much wider than a standard entryway.) For smaller headers the distance between the header and the top plate may be taken up by cripple studs (partial studs). Always make sure your rough opening is plumb, square and true.

For my particular situation, I was afraid to remove any more siding to replace the sheathing because the siding was dated from 1978, and I couldn’t find an exact match. Replacing the siding for the entire house was not an option. My solution was to sandwich a sheet of rigid foam board between two 2-by-12’s (to provide a thermal break), and to install the header not just over the door frame, but extending all the way to the corner of the house as well as over the second stud bay on the opposite side of the door. I doubled all the studs, and fastened the header flush beneath the ceiling top plate and over the studs, allowing the 82-inch high rough opening (accounting for the floor plate, which was still in place). I nailed the heck out of everything, and installed 4-inch wide sheet metal strapping the framing, running from the top plate, across the header and over the interior face of the new studs. I riddled the strapping with nails driven into all the framing components.

Other options include replacing the sheathing, or installing new steel let-in or wood diagonal braces to keep the shear flow from the corner to the foundation. I reiterate: If you’re dealing with non-structural sheathing, consult your local building official for acceptable methods.

A Better Way to Frame a Door in Non-structural Sheathing

EHT reader and professional engineer, Gerard J. Duhon of Texas-based Engineered Foundation Solutions, offers a by-the-book method of framing a door without structural sheathing.

“The space which was available to the author was very limited, so there are few options,” says Duhon. “Two options are available, one involving steel sheet and one involving plywood sheet. In both cases, a sheet of the steel or plywood material must be cut to fit from stud to stud and plate to plate. Both sides of the doorway should have this sheet installed. The plywood should be ¼” thick, and can be attached to studs and plates with 10p nails. The steel should be 14 gauge, about .075” thick, and can be attached by drilling the sheet and using #10 screws. A quicker attachment is to drive concrete nails with a powder-actuated gun. Observe safety and personal protection if the gun is used. 14 gauge steel plate can be obtained from steel suppliers for about $50 for a 4 x 8 sheet.

“To finish the wall, if plywood is used, use construction adhesive to place ¼” Sheetrock over the plywood, to match the thickness of the adjacent sheetrock. If steel is used, the thickness is minimal, finish with the normal sheetrock thickness, use construction adhesive to hold in place. The repair above will yield the equivalent resistance to shear as the let-in bracing, but would be inadequate for resistance to seismic and windstorm perils.”

Editor’s Note: Thanks for the advice, Mr. Duhon. Our staff is always anxious to learn better practices in home improvement, and pass along this information to our readers. You can visit the website of Gerard J. Duhon, P.E. at www.texashomeengineer.com.

Point of No Return

Once the rough opening was constructed I used the Rotozip to cut away the sheathing and Styrofoam insulation from the entryway. I then used the same tool to cut the outline of the door frame through the metal siding at the top and bottom.

My next move was made from the outside of the house, where I marked plumb lines on the sides of the door frame, connecting my top and bottom cuts. I followed my cutlines with a lightweight 18-volt Makita circ saw, using a homemade edge guide that I built a couple of years ago. The thin kerf of the blade made short work of the siding, and as I zipped up the second side of the frame, the metal panels fell to the ground with a glorious crash. I then removed the floor plate between the trimmer studs, and the rough opening was ready for business.

At this point I felt a splash of mixed emotions. On one hand, demolition is kind of fun and exhilarating, and I got a surge of adrenaline while thinking, “Wow, I’ve just put a big hole in this house.” That was followed by a wave of panic as I fretted, “No turning back, now—you’ve gotta fix this.”

Installing the Door

I picked up the pre-hung fiberglass door at my local Lowe’s Home Improvement store (www.lowes.com). It’s a Therm-tru door, which is well insulated for weather protection and comes pre-primed with pre-cut holes for the door knobs. The installation procedure for this door is basically the same as most other pre-hung doors. In some cases, a split-jamb door may be required for thicker walls, because they install from both the interior and exterior of the house to sandwich the wall between the split jamb.

This article depicts a single-jamb door that tilts into the rough opening from the outside. I had to decide whether to set the brick molding of the new door into the metal siding, so the siding butts against the side of the trim, or if I should set the brick molding on top of the siding, concealing the cuts. I opted for the latter method so the brick mold would hide any rough cuts in the metal. However, the protruding profile of the siding meant the door was pulled slightly to the exterior side of the house rather than being flush with the drywall on the interior side. This positioning made the interior-side trim work more difficult—just something to think about in case you try this at home.

Before installing the door, wrap the rough opening in flashing. For ground level doors, a sill pan is recommended. Since this was a second story door, I went with continuous aluminum flashing beneath the sill, and used some flexible adhesive flashing from Cofair Products around the top and sides, lapping it over the surrounding sheathing and tucking it behind the siding.

Apply large beads of caulk over the sill flashing. Also, apply a bead of exterior-grade caulking around the back of the brick mold around the entire perimeter of the door. Tilt the door into place.

At this point I pressed the brick molding flush with the metal siding and drove a couple of screws into the door jamb to hold it in place temporarily. Plumb the hinge-side of the jamb first. Using a 4-foot level, plumb and level it both right and left, inside and outside. When positioned, drive screws through the hinge side jamb into the studs using 3-inch exterior-grade screws. Leave the screws loose. Place wood shims between the opening and jamb, above the temp screws and behind each hinge location. Check again the jamb side is plumb and straight, then finish driving screws in the middle, then the top and bottom. Once the hinge side is secure, you can adjust the rest of the frame and fasten in the same manner. Remove excess shim material by cutting it away with a razor.

From that point forward, it’s all a matter of sealing the door and addressing the cosmetics. I used some Lexel sealant to double-seal the exterior side of the door, and then installed drywall and decorative trim, filled the fastener holes and repainted everything. I installed a doorknob and deadbolt, and that completed the new back door that conveniently accesses our nice, new deck.