Hydronic radiant heat systems warm the home, inside and out.

Heat rises, and a source of heat at your feet is a great way to stay warm and cozy. Rather than using air currents, radiant heat floor systems provide direct heat, similar to standing in the sunlight on a chilly day. When the entire floor is heated, it becomes a large radiating surface that generates heat outward to all areas of the room. When compared to forced-air heating, these radiant floors can reduce a home’s energy usage by 25 to 30 percent, according to the Radiant Panel Association, a trade organization for the radiant heating industry.

Heating Homes with Hot Water

In addition to direct heat, radiant systems offer several key benefits. They consume less energy, which is good for the environment, and produce less dust than forced-air systems. Silent operation is another bonus. Plus, today’s systems have simple yet incredibly smart controls that can target and maintain the level of comfort in specific areas of the home.

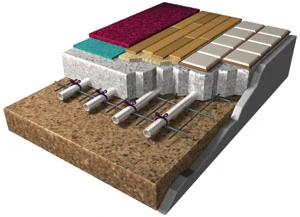

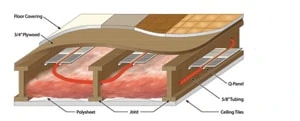

Hydronic systems utilize flowing hot water to provide the floor’s pervasive warmth. Such systems generally feature under-floor piping that carries hot water across the floor. Most of these systems are installed in new-construction applications, although in some cases they can be retrofitted during a remodel. Hydronic systems can be powered by gas, oil, electricity or solar energy, making them both flexible and economical when used for whole-house applications. They can also go under most types of flooring, including wood, carpet, stone, tile and laminates.

Strength in Tubing

Years ago, hydronic systems were built with metal tubing placed in a concrete slab. Unfortunately, as the concrete shifted and cracked over time, so did the pipes. Today, most modern hydronic systems are made of cross-linked polyethylene (PEX) or rubber tubing, which can take more stress and strain than the metal tubing used in older systems. The cross-linking process makes the tubing very strong at high temperatures, and the flexible plastic moves with the natural movement and settling of the house, without leaking or cracking.

The hydronic tubing is usually embedded in a concrete slab or a 1-1/2-inch-thick concrete overlay on top of a wood floor. However, the tubing can also be suspended in the space below wooden floors or stapled on top of subfloors. Almost all tubing for hydronic systems is guaranteed for 25 years, with a lifetime expectancy of 100 years.

The water is then sent through the tubing via a circulator pump. Additional materials such as manifolds, mixing valves, expansion tanks and thermostatic controls are designed into the system to fine-tune the heat for optimum comfort.

Before a radiant system is installed in your house, the contractor or system supplier must calculate the amount of heat that your house will lose on the coldest day of the year in your location. This heat loss is expressed in terms of BTUs or British Thermal Units. The system is then designed so the heat output from the radiant floor exceeds the heat loss from the house. This is accomplished through a combination of tubing spacing and water temperature.

Outdoor Applications

Homeowners residing in milder climates know what a big problem snow accumulation can be. Thanks to hydronic radiant heating, you can say goodbye to slipping and sliding on icy sidewalks and shoveling snow. Even in moderate climates, the location of a sidewalk, driveway or patio beneath the shade may encourage snow or ice accumulation. Radiant tubing with antifreeze can melt the accumulation, making these highly trafficked surfaces safe and dry for visitors and family members. Embedded in the concrete, these snow-melting systems can be installed alone, or as a component of a larger radiant system.

For those cold-weather homes, a roof de-icing systems may be another smart investment. Freeze/thaw conditions can form ice dams and icicles around eaves, drains and valleys, which cause structural damage and leaking. Snow accumulation can also create a heavy weight load on roofs. Some de-icing systems use PEX tubing to transfer heat to a customized aluminum panel. De-icing systems are available for all types of applications, including new construction, remodeling and existing roofs.

Whether they’re used for melting snow or warming floors, hydronic radiant systems do a great job of efficiently heating the living space throughout the long months of winter. For more information, contact the Radiant Panel Association at www.radiantpanelassociation.org.

Side Note 1

The Direct Approach: How Radiant Floors Heat the Home

Every home—no matter how well insulated—is constantly losing heat to the outside, and forced-air heating systems are constantly working to replace this lost heat. Similarly, our bodies also lose heat to the colder objects that surround us. Heat always flows toward cold, and this loss of body heat causes us to feel chilly.

Radiant floor systems work so efficiently because they directly heat objects in the room instead of just the air in the room. This direct heat warms you, the floor, the sofa, the recliner, the kitchen table, etc. Since these objects are warmer, they don’t sap as much heat. The end result is an overall feeling of warmth and comfort. In fact, the air temperature in the room can be considerably lower if your body is in a room full of warm objects, and you’ll still feel very comfortable. Many people who use radiant heat lower their thermostats to 65 degrees and feel more comfortable than they did when setting their conventional heating system to 70-72 degrees.

Side Note 2

Checklist for a Hydronic System

If it’s your first time dabbling in radiant heat, or you just want to be sure it’s done right, then you should get a loop CAD (Computer Aided Design) of your tubing system drawn by a Radiant Certified Designer. The CAD maps out the installation of your tubing system throughout the home, including the various system components. A loop CAD with a materials quote is $75 from PexSupply.com. Other materials and components of an in-slab hydronic heat system include:

ThermaPEX Tubing. A hydronic system uses cross-linked polyethylene tubing with an oxygen barrier. It is flexible enough to bend easily and strong enough to be approved by all major plumbing and heating codes.

Manifold. The manifold is the hub of a radiant heating system, connecting to the supply and return lines with as many ports as you have loops of tubing. If more than 12 loops are in a system, multiple manifolds may be necessary.

Circulator Pump. The system requires a quality pump to circulate the water throughout the system. If there won’t be potable water involved, a cast-iron pump is a cost-efficient way to get the job done.

Check Valve. This valve ensures that water can only flow one way through the system.

Mixing Valve. Boiler water cannot go directly into the hydronic radiant system. The water must be mixed with cold water, sending 180-degree F water to heat your floors.

Thermostat. The interface between you and your heating system, the thermostat will control when the heat is turned on and how long it stays on to achieve the desired temperature in the room.

Sensors. In-slab sensors will communicate to the thermostat the temperature of the slab, while floor sensors will communicate the surface temperature of your floors to prevent any gapping, cupping or warping due to excessive heat.

Expansion Tank. The expansion tank maintains proper pressure within the system.

Air Eliminator. This device removes all excess air from the system to ensure silence and a steady water flow during operation.