Great-looking, Long-lasting and Environmentally Friendly

Lucky Kavalaukus, age 89, is sitting on the front deck of his Highland Lake cottage telling me that our cottage on Carr Island in New Hampshire, which he looks at every day, does not have a new metal roof on it. I have to show him pictures to prove that it does.

The classy two-tone patina top on our cottage, which arrived on a retired party boat with the roofer, does not fit many people’s expectations about what a metal roof is. Things have changed.

I had just been up on the roof taking photographs to illustrate this article about metal roofs for Extreme How-To. Roofers do have a different perspective on things. From my perch I scanned the sky for the eagles that the builders had seen, and watched the loons bobbing in the boat channel.

Our Carr Island camp was built as a hunting and fishing lodge around 1860, and very little had changed except that a series of leaky asphalt roofs had begun a kind of morphing process that over time demanded selective tear-downs and rebuilds and some pretty funny comments in the guest log. The area around the chimney and over the main bedroom especially was susceptible to wet nights. We repeatedly lugged contractor bags stuffed with nasty, sharp-edged shingles to the town dump.

Just finding roofers to come over by boat to repair the island cottage roof was so problematic that one year I drove my own roofers from upstate New York to New Hampshire to take care of it. For two days I cooked inside the cabin while the man and his son scrambled around a very steep pitched roof. Talk about a stimulus package. This team spent much of their earnings on New Hampshire’s legal fireworks.

Lots of folks like metal roofs because often they can be installed over an existing roof, which eliminates the need to add wasted asphalt shingles to the country’s landfills. In New Hampshire, however, you can only cover one layer of pre-existing roof. You definitely need to look into the building code before you begin.

While I came to understand what good stewardship of land and materials meant later in life, I have no idea where those shingles went, but I have to assume they are percolating in some sanitary landfill. And yes, I do feel bad about all of those layers of leaking roofs. But my sister Bonnie lives in green-friendly California so she feels even worse.

One of our trusty resources for this new project was Green Remodeling (Changing the World One Room at a Time), a book by David Johnson and Kim Master. Johnson and Master wrote that the type of roofing we use has serious consequences on our health and the environment: “Sloped roofing materials, such as asphalt-based rolled roofing and shingles, will offgas toxins when heated by the sun. Flat roofing materials, such as tar and gravel, will also continually offgas when heated by the sun, emitting known carcinogens such as VOCs from asphalt, including benzene, polynuclear aromatics, toluene and xylene.”

The authors say that 78 percent of the total roofing dollars spent in the U.S. is spent on re-roofing, potentially exposing homeowners to high levels of toxic fumes every time a roof is replaced or repaired.

Those and other ambitions for our renovation of the old hunting cabin helped us choose a “greener” metal roof made largely from recycled materials. As one expert said, your roof should last as long as your mortgage, and the product we chose had a 40-year transferable warranty (from the point of installation). Metal is also the preferred material in rainwater catchment systems—a growing area of interest in regions in the U.S. where water conservation is a serious issue. For example, in some instances, homeowners are not allowed to use water from their roofs, even to water their gardens.

DIY and the Internet

There are a lot of ways to approach a DIY project—really do it yourself hands-on, or pay somebody else to do it according to whatever research you’ve done. In both instances, hitting the hammer or the keyboard, things get done to a higher level of expectation.

For us, DIY meant carefully sleuthing the Internet and not just taking a manufacturer’s claims at face value. Many parts of our project sprang from the Internet, ranging from selecting handmade drawer pulls for the kitchen to looking at local architects’ portfolios (we chose Charles Michal of Weller & Michal in Keene).

Michal had spec’d our designs for a roof of asphalt shingle, so he wasn’t thrilled when we told him our research had led us to metal roofing as today’s green solution to roofs. It’s hard to say what our builder, Peter LaRoche of Peterborough, thought about metal roofs. LaRoche’s eyeball rolling was something we looked for in any case. The words “metal roof” had his eyeballs rocketing.

My sister Bonnie is a born cyber sleuth and an exemplary consumer—the kind that keeps all the receipts and quickly replies with warranty cards, sometimes the next day. She says one misconception about shopping the Internet is that cyber space is not necessarily cheaper. For example, while doing extensive research for lighting designs for the entire cottage, she found the exact same products at a better price “offline” at a trendy interiors store in her own Los Angeles beach neighborhood.

Go figure.

DIY or Hire Somebody Else to Do It

Our quest to end leaking roofs forever led to the metal roof manufacturer Classic Metal Roofing Systems of Piqua, Ohio. We liked that they were a second-generation, family-owned business, used 98-percent recycled materials, and their products are all made in America. To top it off they had their own dealer network trained in Ohio for professional installation. Plus they made good-looking roofs in colors, profiles and thicknesses to match the “feel” of our project. Just one call to Classic got us a huge customer sample folder with actual size materials.

Carr Island gets heavy snow, so that was another consideration for our roof. If improperly installed, metal roofing can heat up and suddenly let go with a sheet of ice crashing onto unsuspecting people or property below. We also had an extremely hot upstairs bedroom area, and metal reflects more heat than asphalt.

Given these considerations, we hired Gerry Donaghue of Donaghue Construction, to drive the project. “You’ve got to understand how to manage the snow coming off a roof,” Donaghue says. “Installing metal roofs is not rocket science, but it must be installed correctly to make it work. If it’s a hand’s-on DIY person, I strongly recommend hiring a professional to prep you for the job.”

Getting good advice is a wise investment. Donaghue says the average price for the projects his company does is in the $18,000 to $22,000 range, but he has a big home this summer that will cost $50,000 to roof. Metal roofs clearly cost more than asphalt shingle. Donaghue estimates that as of late summer 2009, the cost for materials is about $6 to $12 a square foot whether it is steel or aluminum, standing seam or profiled shingles.

Most metal roofs are Energy Star efficient and qualify for up to $1,500 in federal tax credit.

We installed slate-like shingles on the pitched roof and standing seam on the new porch additions, where the pitch was too shallow for a profiled surface. Standing seam (long verticals) is what you commonly see on American metal roofs where the metal roof market accounts for just 8 percent of the total roofing market. That may seem small, but it’s about double the percentage of just 20 years ago.

Metal Roofs, Then and Now

When they think of metal roofs, most people think of franchise restaurants with their brightly colored, come-hither-looking tops. Or, they think of agricultural metal roofs with screws rusting right through the metal into the building.

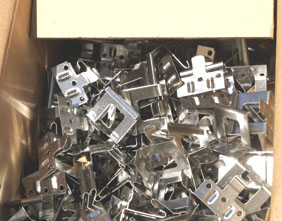

Today’s modern metal roof always has some kind of clip locking system with interlocking panels, so it can float with the heat, leaving the panel to contract and expand depending on the temperature. The clip system allows the roof to do that. The clips also keep the roof flat to the decking material so that when air comes across the roof, it can’t lift the roof, which is why you see more metal roofs in coastal areas. Classic Metal Roofing even has testimonials from people whose roofs survived Hurricane Katrina.

Donaghue says, “All of the better products on the market have a slotted system or a clip system. Standing seam goes down with a screw-down, stainless steel clip. On the shingle products, those are aluminum clips. You can use aluminum or steel. On a lake you can use steel, and it won’t affect the warranty, but if you are near the ocean you have to be a certain distance from salt air to use steel.”

Wind and Weather

No surprise here—some seasons are better than others to re-do any roof, including metal, which is slippery when wet. Donaghue suggests that, barring a weather-related catastrophe, you, “Pick a season that’s right for you.” Frost, he says, can sometimes take hours to leave. Summers can be too hot. He always wears fingerless gloves year around because of the ever-present sharp edges. His best season in the Granite State is fall.

The upside? Roofing, or re-roofing, often is a job you can schedule to fit your time frame.

Other Tips from a Pro

“If you are doing the work yourself, the easiest thing to do is to use aluminum products because they are lightweight and easy to work with. Steel is much more difficult—harder to bend, heavier, more difficult to form and less forgiving,” says Donaghue.

“Next, I would definitely recommend aluminum in a shingle rather than standing seam. Shingle is easier to put on (panels come in small sections). Once you have the basics on how it goes together, it’s easy and they are lightweight.”

The real problem he says for DIY’ers is staging, including having the right brackets. But before we get to brackets, he advocates photographing every job before you begin and really studying the roof as it exists. Things to look for are problem areas like rot, dips, swales, missing shingles, or anything else out of the ordinary. Often DIY’ers do roofs for others, and most homeowners are unwilling to climb out onto a roof to inspect areas of concern.

Determine the existing material: asphalt, fiberglass, wood shake, wood shingle, slate, asbestos, clay, concrete or something else. Roof styles themselves can be gable, hip, intersecting, mansard, gambrel, saltbox or Dutch hip, among others. In order to get a handle on your plan of action, Donaghue strongly recommends that you draw your roof. If you don’t have plans for your home, use a clean sheet of grid paper. Imagine what your roof looks like from the top looking down—use the point of view of an eagle, not a worm.

Having a good understanding of the structure, including overhangs, will help your organizational skills. Then there is the ability to get onto the roof and having the right tools at hand. For staging, “You can use the wooden staging brackets that you normally use on an asphalt roof. Tool supplies and lumber yards have them.”

As for safety he quips, “Don’t do it at all.” What makes roofing different from other home building projects, he explains, is that if you fall you are going to come down off the edge to the earth below, in a heap. “You have to be very comfortable up there on a roof. I’ve had airline pilots come up, and they couldn’t take it,”

“They weren’t comfortable,” he adds. “You have to be really careful. And a helper has to be balanced and able to climb around. Most of the guys we hire are younger—mid-twenties. They are lightweight, agile and intelligent. No goofballs up there.”

Donaghue says installing asphalt takes less thought; you just lay the material down and nail it. “Metal roofers don’t have to be finish carpenters, but they do have to be more of a craftsman. Guys who do all types of siding are usually pretty good at it. You need a person who can think through a process of interlocking panels, forming them, using the snips, bending; there is a lot of hand work required.”

Chimneys, especially rough natural stone, skylights, vents, satellites, antennas and lightning rods present more challenges to forming and fitting details. “The average skylight,” he says, “will add 2 to 4 hours of labor. Skylights are complicated because you have to take apart the flashing system. On chimneys you often have to take the lead off first. It’s always something different.”

Most modern metal roofs have some kind of foam panel that adds insulation value in a roof and cuts down on noise. Another roofing material of prime importance is roofing paper. Donaghue uses Aqua Guard, which he gets from Classic Metal Roofing. “All metal roofing requires a minimum of 30-pound felt between the roof deck and the panel,” he says. “The decking could be plywood or a layer of existing shingles.”

While called “felt,” today’s roofer is probably using a kind of fiberglass matt. Most are synthetic products with names like Aqua Guard, Roof Top Guard, and Titanium Shark Skid. Costs range from 10 to 11 cents a square foot for paper, and 12 to 20 cents for the felt.

Being trapped on jobs by New England’s bad weather has made Donaghue a true believer in the value of using synthetic products according to the manufacturer’s directions. “It does a couple of things,” he says. “It allows you to strip the old roof, put the paper down, and if you don’t get the roof on that day, you are OK with an open roof. It’s not going to leak.”

Leaks are a roofer’s worst nightmare, but also their reason for being, especially where mold and mildew cause problems.

For my sister and me, the classy new two-tone patina metal roof on our rustic new/old cottage means no more leaks. And no more jokes in the guest log book about them either.

Editor’s Note: Laurie Mercer is a freelance writer from Honeoye Falls, New York. Along with her sister Bonnie, she is restoring and remodeling Carr Island, a family property on Highland Lake in Stoddard, NH. To see a video, search for “Carr Island” on YouTube. Mercer’s website is www.lauriemercerpr.com.

Side Note

Steel Shingles with “Wood Shake” Beauty

Best Buy Metals takes metal roofing shingles to a whole new dimension with steel roofing that looks like wood shakes, natural hand-hewn slate, tile and much more. Designed with beauty and longevity in mind, these roofing materials carry warranties from 50 years to a lifetime. Best Buy Metals’ products are DIY-friendly, featuring designer steel roofing shingles, as well as matching trim and accessories. They can be purchased as an entire roofing package for ease of installation.

Best Buy Metals’ KasselWood steel shake roofing, shown here in a New Cedar finish, is a four-way interlocking system, producing a highly wind-resistant, attractive roofing material. KasselWood features a four-layer Kynar 500 paint finish and a lifetime warranty. KasselWood is easy to install, requiring only common tools. KasselWood has clips built in, which makes for a faster installation. Best Buy Metals carries a wide variety of metal roofing materials, and sells to homeowners and contractors nationwide. For more information, visit www.bestbuymetals.com or call 1-800-728-4010.