By Charlie Self

A Handy Technique for Treating Tools, Blades and More

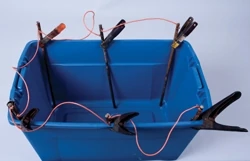

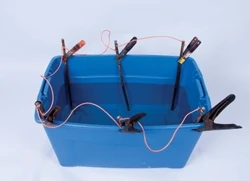

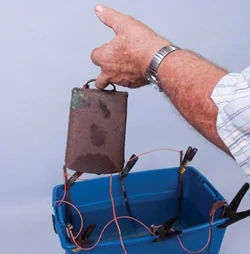

Most of us have at least a small collection of rusted items—items that need a lot of work to make useful or decorative, so we get out the sandpaper and wire brush. The decorative bits and pieces usually still look pitted and unattractive after all the work, and rust is still hiding under any finish. Using an old battery charger and a non-conducting container can rapidly cure most, or sometimes all, the pitting problem while removing the rust. An old friend, Bobby Weaver, has been removing rust from old saw blades using this technique, and had decided to do some other items, too. In this case, he had a couple of cow bells he wanted to use as parts of lawn decorations. The rust was bad enough that he didn’t want to wear himself out trying to remove it, so he used his setup for de-rusting saw blades and plane irons. He needed a new container: The old container had a burn slit down one side where a blade had touched an anode to create a short. Bobby picked up a tub at a local store, making sure it was long enough to hold his saw blades. If just the cow bells or similar sized items are done, a five gallon plastic bucket works very well, too. Sizing the container to the items being de-rusted saves time and hassle. The cow bells are much too small for this tub, but saw blades fit well, as do shovel blades and rake heads.

Safety

For the most part, this is a reasonably safe procedure, but it’s essential to remember that you’re working with electricity and an alkaline substance (washing soda). Some people say shutting the charger off while working on the anodes and placing the cathodes (rusty objects) is safe enough. Personally, having been bitten by electric gremlins too many times, I like to unplug the charger before messing with anything down the line. That’s why I don’t change a table saw blade with the saw plugged in; a switch failure or voltage surge could cost me some body parts I’d rather not give up. A 12-volt shock isn’t much, but wet wires and floors and other problems can create dangerous conditions, so unplug the charger. It takes only a second. If your hands get wet, stop working with any wiring until they are thoroughly dry. The washing soda is alkaline, so if you’re sensitive to such substances, wear rubber gloves. Remember: Anodes are positive and red; cathodes are negative and black. Make sure anodes and cathodes are like East and West: Never the twain shall meet. Bobby shifted a tub one day and burned that 16-in. slit down its side.

For this job newer battery chargers don’t work very well. Bobby picked his up at a flea market; it is quite old. I’ve tried my newer computer chip-laden automatic charger and it doesn’t work well at all. He’s also found that using six volts works better than using 12 volts. Additionally, a well-ventilated space is needed because the process vents hydrogen and oxygen as it breaks down the water.

Materials & Tools

Items needed for an electrolytic rust-removal chore are not extensive:

Container. A non-conductive (plastic) container like those made by Rubbermaid is required.

Electrolyte booster & water. We used washing soda at 1 tablespoon per gallon of water.

Sacrificial anodes. We used 20-in. lengths of rebar, but almost any ferrous metal works. Stainless steel may also be worth experimenting with, for those with the time. Unless you have a power hacksaw, it’s a good idea to get the seller to cut your rebar, so determine lengths needed before you buy .

Battery charger. It’s possible to use a car battery, but is not as effective. I’ve never tried it that way, but you might need to recharge a battery several times. Too, you’re locked into one voltage, 12 volts with most modern batteries.

Clamps. Bobby used his oldest, most beat up 2- and 3-in. spring clamps, which worked well. Also, a 1/4-in. bit in a good drill is needed to drill through the rebar. The rebar may also be scraped and the wire wrapped around tightly, or an alligator clip used, but drilling through gives a better connection.

Method

Place the anodes around the rim of the tub, using clamps. You can wire the anodes together before or after placement. We did them before. Make sure the wires are firmly twisted in place. Bobby likes to use old, large office clamps on those that don’t feel secure. Fill the tub as far as needed with water. Pour in the washing soda. Mix well. Using wires with alligator clamps, hook the rusty parts up as cathodes (negative, black if you’ve got the right color alligator clamps). Settle the parts in the tub, making sure they do not touch the rebar anodes. Hook the battery charger’s positive clamp to the first anode. This clamp must stay out of the water or it will eventually erode. Hook the battery charger’s negative clamp to the wire clamped to the rusted parts. Plug in the battery charger. Look for a stream of bubbles rising from the rusted parts. This indicates the setup is working. The bubbles are hydrogen gas, and oxygen, which is why a well ventilated space is needed.

Go enjoy a glass of tea and a sandwich. Come back in several hours: Small objects may be done, but for larger objects you’ll see a rusty looking scum on the water. Give those a few more hours, or overnight. There is no problem with time using this process. When the rust is gone, the process quits working even though it’s still hooked up. We ended up leaving the cow bells in the solution for several days.

You can see from the shots of me using a sanding block on the big cow bell that the oxide is soft. It just about powders off, but the sanding block doesn’t get in any remaining pits, or into seams. I did some of that with a brass brush, but we’ll put it back into the solution when our power situation stabilizes to get a cleaner overall look before I paint it. There will still be pits, and a few raised spots, but these cow bells already sound pretty good.