By Larry Walton, Photos by Smith-Walton.com

Replacing the Starter in a Ford Super Duty

Years ago when I had starter issues, I’d just park on a hill, or get a friend or two to give me a shove, and with a quick drop of the clutch we were off and running. Not so, today. Not only does my truck weigh 3-1/2 tons empty, it’s an automatic. So when the starter quits working, the repair must be immediate.

Home Garage Diagnostics

Now some of you are saying, “How’d you decide it was the starter and not something else?” Good question, especially since it takes so many automotive components to get a vehicle started.

OK, let’s assume that the engine has everything it needs to run (fuel, air and spark—for gas engines—all happening in the right amounts and at the right time).

In addition the starting process is to get the engine turning. This is why hand cranks were used on the earliest cars, as well as why the “push start” method I described above works. They get the engine turning so the fuel/air mixture enters the cylinder and gets compressed for ignition, at which point the running process takes over for the starting process.

To get the engine turning by simply twisting the ignition key requires a good deal of electrical current turning a heavy-duty electric motor. This starter motor turns a pinion gear, which meshes with a ring gear on the flywheel or flex-plate to turn the engine.

Now, let’s say your car doesn’t start. The question remains, why not? If you turn the key and you hear nothing but perhaps some clicking, you probably have a dead battery. Even then, the problem could be corroded battery cables, a loose ground to the battery, a faulty connection to the starter, or an issue with the ignition switch.

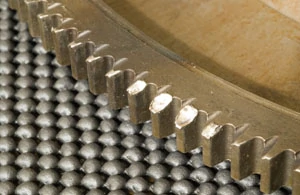

However, if the starter is clearly turning the engine over, you could be missing fuel, air or spark. If the starter is making noise but not turning over the engine, you could have a starter issue at the pinion gear, or it could be missing teeth in the ring gear that connects the starter to the engine.

Narrows it right down, huh? In the case of my truck, I figured it wasn’t a battery problem because I recently replaced the stock batteries. I thought of the ring gear, but figured it would be damaged in only one of the four positions that the engine usually stops, and this problem was too consistent for that.

Because the starter was turning but apparently not engaging well with the engine, even if it was a flex-plate ring-gear problem, we would want to replace the aging starter anyway. If we began with replacing the starter and it fixed the problem, we could consider the job done.

So that’s what we did, that’s how it played out, and here’s how we did it.

Getting Started

The first thing we did was procure a new starter. You can pick up one from the local parts store, but if you have a friend with an auto shop he may be able to get one for you at wholesale.

Next, we took the truck to my son Tim’s shop where his buddies had left a mess doing an engine swap. After doing some shop cleaning, we pulled the truck in and let it chill.

Depending on the type of vehicle, a lift or jack stands would be handy, but my truck has enough room at normal ride height to work on the starter from a creeper.

We disconnected the battery ground cables (my F-250 has two batteries). This is an important step. The fat cables going from battery to starter should be fair warning that a good amount of juice gets directed to the starter leads.

Then Tim cleaned off the starter and the area around it. This is a good idea when you are doing some work overhead. Safety glasses are also very helpful, because every dislodged bit of dirt is going to drop straight down on your face.

After taking a quick look at where the wires connect to the starter assembly, Tim loosened the mounting bolts so he could remove and rotate the starter to get to the wire leads. This made disconnecting the wires quite simple.

Checking for Tooth Decay

With the starter out of the way, grab a flashlight and find an angle where you can see the teeth of the ring gear. Inspecting the condition of the ring gear is an important step in this install. Because this starter was having trouble engaging and disengaging the ring gear, damaged teeth on the ring gear was a distinct possibility.

The starter opening in the case allows you to see only a few teeth at a time. Tim used a breaker bar and a socket on the crank pulley to turn the engine over a little at a time while I watched the teeth of the ring gear.

Tim watched a timing mark on the crank pulley to make sure that he turned the engine a full revolution to give me a chance to see all of the teeth.

Having passed its ring gear inspection, the truck was ready for the new starter. As is often the case, putting things back together in reverse order of taking them apart usually works best. In this case, Tim made the electrical connections on the starter before final positioning.

Perhaps the most critical aspect of the starter install is making sure that the flat surfaces of the bell housing and starter flange meet flush all the way around. Firm pressure on a normal ratchet should be all the torque you need.

With the starter secured, re-attach the battery ground cables. Make sure all tools are removed from the engine bay as well as from under the vehicle.

Turn the key. In our case, the starter replacement solved the problem. The truck started without complaint, and we were off to return the original starter core to the parts store for our core charge refund.

Pay attention to instructions for returning the starter core, including the warning that the core must be returned in the new starter box.

Step-By-Step

Side Note

Hard Core

Several different types of car parts have non-moving parts that are in perfectly good condition when the other components need to be replaced. Examples include brake calipers, distributors, power steering pumps, cylinder heads, alternators and in our case, starters.

If the part can be bought rebuilt, you will probably be charged a “core charge,” which is refunded when you return the old part to the parts store. So, when your hippy friends start talking about their green activities you can be all, “Hey man, I put a recycled starter in my truck and I recycled the old one.” Now, maintain that smug look as you leave them in exhaust and tire smoke.