I live in the rural outskirts of Birmingham, Alabama, in a sleepy country town where most of our Sunday afternoons are spent sitting outside, visiting with friends and family. And we’re multiplying. Our family is growing with new additions, so our available seating is in decline. I decided to build a couple of lawn chairs from cedar. These two chairs—one a single-seater, the other a bench—can be built in a weekend without specialty tools and using only basic carpentry skills. It’s a fun DIY project, and one that you can customize in a variety of ways. I used some old extension service plans I found at my grandfather’s house, which I modified slightly. Here’s a look at the basics of construction.

Gather Materials

You can find ready-made chairs in a similar style that are made of vinyl, but I thought that for such a traditional style of furniture, vinyl just looks too plastic. I definitely wanted the classic look of wood for the furniture. Although pressure-treated wood can be used, I opted for western red cedar. CedarOne from Weyerhaueser contains natural preservatives in the wood fiber that help it withstand insects and harsh weather conditions. It’s also a beautiful building material with a rustic look that is lightweight, stains well and resists decay, which cuts down on maintenance. I don’t expect these chairs to last forever, but the cedar would give it some extra life and character.

Fasteners are another must-have. The project requires strong, waterproof glue and exterior-grade screw and nails. I used galvanized 6d and 8d nails, along with 1-1/4-inch and 3-inch decking screws.

Getting started, a good rule of thumb is to gather all your building materials, tools and fasteners at the work site. Keep everything organized to prevent return trips to the hardware store. A comfortable work site is also important. I was building in my back yard, which afforded plenty of space to work and lots of natural light. I set up some sawhorses and used a couple of plywood sheets as a tabletop.

Leg Assemblies

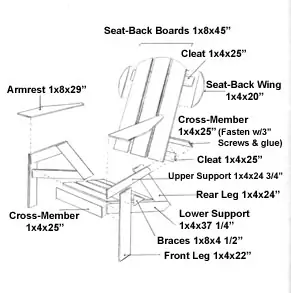

Begin with the leg assemblies. The leg assemblies are built the same way for both the single- and the bench-style chairs. For each leg assembly, use 1-by-4 stock to cut two of each component: 22-inch-long front legs, 24-inch rear legs, 24-3/4-inch upper supports, and 37-1/4-inch lower supports. Mark the pieces so you don’t mix them up.

Fasten the front leg to the upper support as shown in Fig. 1. The leg goes on the outside of both the supports, and the “outside” will swap sides when you build the other leg assembly—remember, one leg assembly should mirror the other one, not duplicate it. Make a simple overlap joint, aligning the two pieces flush at the two foremost edges. Use a square to make sure you’re joining at 90 degrees. Apply a quality waterproof glue at the joint—a strong polyurethane adhesive like Gorilla Glue works great—and drive three 1-1/14-inch exterior-grade screws to secure the connection.

Note: Throughout this project, anywhere you drive screws you should first drill pilot holes and countersink the screws to avoid splitting the wood.

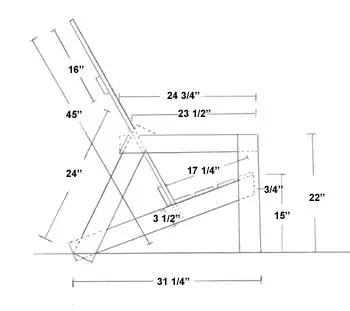

Next, install the lower leg support to the inside of the front leg with screws and glue. Take note of Fig. 2 (see pg. 63); the front end of the lower support is cut at an angle parallel to the edge of the front leg, and set back 3/4 inches to allow for the installation of the front fascia board (cross-member) of the chair.

The upper edge of the lower support should be located 15 inches from the bottom of the front leg. In relation to the front leg, this sloped angle of the lower support represents the angle of the chair’s seat, laid back for a comfortable sitting position. You can play with the lower support’s angle in relation to the front leg, but the angle must match the support’s angle on the other leg assembly, or you’ll be sitting kind of funny in your poorly constructed chair. I used a 71-degree angle, and found it created a comfortable seat. Make note of your angle with a protractor and transfer the same angle to the other leg assembly.

The rear leg is then fastened to the inside of the supports. Construction of the leg assemblies is the trickiest part of this project. After fastening the front leg and upper support, you’ll need to initially lay out the other two pieces loosely, sliding them around to adjust their positions and marking their installation locations accordingly. You’ll need to mark the angled front cut of the lower support in place, make the cut, then replace the support and fasten securely. Because of the various layers of boards, the leg assembly won’t sit flat on a workbench, so use some scrap pieces of 1-by-4 to support it as needed. Fasten with three screws and glue at each joint.

Once assembled, use a jigsaw or hand saw to trim off the excess corners. Then use a T-square along the bottom of the front leg—where the chair will meet the ground—and make a flush line along the bottom of the rear leg and lower support. Trim off this excess wood so the chair will sit evenly on the ground. Use the first leg assembly as a pattern for the second, remembering to build a mirror image, not a duplicate of the first. Note: The leg assemblies for the chair and the bench are built exactly the same; the only difference is the construction of the seat back and length of the seat boards.

Finishing the Seat

Next, it’s back to the saw to cut the remaining chair components. For the single-seater chair, use 1-by-4 stock to cut eight 25-inch-long boards. These will be the four seat boards, the two seat cross-members, and the two seat-back cleats. From the 1-by-4, also cut two 20-inch pieces to serve as the seat-back wings.

Next, use 1-by-8 to cut three 45-inch boards for the seat back. For armrests, cut two 29-inch boards from 1-by-8. Also, cut two 4-1/2-inch pieces of 1-by-8 to use as braces for the armrests.

On top of the lower leg support, make a mark 17 inches from the front upper corner of the support. Do this for both leg assemblies. That mark indicates the back side of the last seat board.

Then, following the plans in Fig. 2, fasten the front cross-member to the leg assemblies with 8d nails and waterproof glue.

The rear cross-member will support much of the weight of the seat-back and should be fastened with 3-inch screws and plenty of waterproof glue. Drill pilot holes and then drive the screws through the 1-by-4 into the rear leg at a slightly offset angle.

Next, using 6d nails and glue, fasten the four seat boards, spacing them evenly. The front edge of the first seat board should project slightly past the front leg with the distance from front to rear at the 17-inch mark.

You can complete the seat of the chair by installing the armrests over the upper supports as shown in Fig. 1. Shape the armrests by cutting off one rear corner from each on opposite sides (remember—mirror, don’t duplicate). Glue and nail along the edge of the armrest, fastening its inner edge flush over the inside edge of the upper leg support with glue and 8d nails. Cut the 4-1/2-inch pieces of 1-by-8 diagonally, using them as triangular braces to support the armrests from the front legs. Fasten the braces with 3-inch screws and glue.

Building the Back

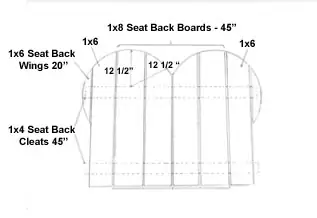

On a flat work surface, lay out the three 1-by-8 seat back boards parallel with 1/2-inch gaps between them. The tops and bottoms should be even. Fasten the lower 25-inch cleat across the boards 3-1/2 inches above the bottom end using screws and waterproof glue. Attach the top cleat in the same way, positioning it 12-1/2 inches below the top of the seat-back boards. Then temporarily tack the wings in place so you can scribe the rounded shape of the chair back all at once. (After scribing, you will remove the wings, cut to shape and refasten them to the seat back.)

Now, scribe the rounded back of the chairs. To do so, turn the back over with cleats facing down. In the center of the middle 1-by-8, mark 12-1/2 inches down from the top. This is the pivot point of the scribing tool. My makeshift scribing tool was a simple wood scrap—a thin piece of 1-by about 14 inches long. I drove two nails through each end, spaced 12-1/2 inches apart. I then positioned one of the nails (now stuck in the wood strip) over the 12-1/2-inch center mark on the middle seat-back board and tacked it in place. Swing the other end in an arc just like the hands of a clock, using the nail at the opposite end to scribe a circular line on the seat back. Scribe this cut line all the way to the outside edges of the two outer seat-back boards.

Remove the scribing tool and cut along the scribed line with a jigsaw. Remove the wings and cut them separately. When cut, fasten the wings with 8d nails and glue, nailing through the edge and into the edge of the seat-back boards. The narrow width of the wings allows the nails to reach through their top and bottom.

Once assembled, the back simply slips into the seat assembly. The lower back cleat rests on the lower leg support, and the back boards rest against the seat’s cross-member. The back can be fastened in place, but I left mine loose so it can be disassembled for easy portability.

Bench Construction

As mentioned, for the bench, the leg assemblies are built exactly the same. However, all the bench seat’s cross-members and seat boards are 45 inches long.

As shown in Fig. 3, I built the back of the bench from four, 1-by-8’s flanked by two, 1-by-6’s, plus two short wings cut from 1-by-6. The bench back is fastened together just like the chair back, except the two 1-by-4 cleats are 45 inches long. Mark the double rounded back by positioning the scribing tool at the 12-1/2-inch center mark on both the second and fifth seat-back boards. Once scribed, remove the wings, cut the wings and back to shape, then reattach the wings. That completes the back—just slip it into the bench seat.

Note: After completing the bench, I noticed that the 45-inch seat boards of the bench had some sag when I sat on them—particularly on the second to last board. I went back a couple of days later and installed a 1-by-4 brace fastened beneath that third seat board. I installed this brace flush between the two lower supports, positioned perpendicular to and along the entire length of the seat board. This brace added a lot more rigidity and stability to the bench seat.

Finishing Up

After building the chairs, I took a few additional steps for a completed look. I puttied the fastener holes and sanded the putty after it dried. I also sanded all the “sitting” surfaces (armrests, top of seat boards, etc.) to prevent splinters. I then ran a Surform tool on the inside edges of the armrests. The Surform (you can also use a rasp or block plane) shaved the sharp inner edge of the armrest to a more comfortable rounded shape.

I also added a stain. Although cedar is durable and will eventually weather to a silvery gray, a finish coat will stretch its life and achieve a handsome, healthy appearance. I brushed on two coats of Cetol 1 in Cedar Tone from Sikkens. The Cetol 1 is a translucent, satin stain designed to enhance the look of wood and protect it from UV rays and water damage.

After the stain cured, I was really pleased with the look of the furniture. And I had a few more seats for those Sunday afternoon get-togethers.