By Matt Weber

New water-conserving toilet valves can save money and resources. Water saved is water earned.

In times like these, money matters a great deal, and saving is the name of the game. Reducing utility costs is a smart way to go. Take the example of Jefferson County, Alabama, headquarters of Extreme How-To. In recent years county residents have seen a steep increase in sewer rates. This is due in large part to some shady dealings at the hands of corrupt county officials, which resulted in the cost of a recent federally mandated sewer overhaul to be three times as much as the original estimate. A household around here pays 57 percent of its combined water/sewer bill for sewer usage, and only 43 percent for fresh water. It seems odd to me that it costs less to tap clean water than to flush it away, but that’s the reality.

Our staff decided to conserve water was by gutting the tanks of a couple of old toilets and replacing the flush and fill valves with some new water-saving devices. Rather than upgrading to a new toilet, replacing the plumbing in a tank is easier, less expensive and can conserve even more water than many “high-efficiency toilets.” According to independent research, upgrading the flush valve alone can save nearly 40 percent when compared to toilets equipped with a standard flapper valve.

We replaced the old ballcock valves in two toilets, both of which dropped nearly five gallons per flush. We installed two different conversion kits, the One2Flush system and the HydroRight system. Both of these products employ dual-flush technology to reduce water usage. To put it delicately, the dual-action valves operate with two separate flushing methods; use a small, conservative flush for Number One (liquids), and a more vigorous full flush for Number Two. The water savings result from the fact that residential toilets generally require only the small flush much more often than the big flush.

One2Flush Dual Flush Kit & Fill Valve

The One2Flush is the first kit we installed, which comes with the flush valve and lever preassembled from the factory. It costs less than $30, and if your toilet currently operates with a float-cup type fill valve, then the flush valve will be all you need. However, both toilets we were upgrading utilized the older ballcock mechanisms, so we also replaced the fill valves. In any case, the installation takes only a few minutes and requires only simple hand tools, like a wrench and pliers.

Begin by shutting off the water supply beneath the toilet. Flush the toilet and scoop out any remaining water from the tank with a cup. Use a rag to dry out the inside to prevent drips, then unscrew the tank supply line that connects to the fill valve.

Replacing the fill valve only takes a couple of extra minutes, and the advantage of the One2Flush fill valve is that it utilizes an adjustable micro-valve on the fill tube. During a standard fill cycle, water is usually draining into the bowl during the refill, which can waste as much as a gallon per flush. To solve this problem, the micro-valve allows you to determine how much water is used during the refill process, regulating the amount that goes into the bowl.

Swapping the fill valve is a direct replacement procedure—just unscrew the retaining nut from the bottom of the tank. Pop it out of the tank and stick in the new one, nestling the gasket in the tank hole and securing it with a new O-ring and retaining nut. The fill valve can also be adjusted by height to match your tank’s specified water line by slightly rotating the cup and sliding it up or down the shaft of the valve. Reattach your water supply line whenever you’re ready to fill the tank.

Next, use a wrench to back the nuts off the two tank-to-bowl nuts located on the underside of the tank. Choose a well lit area for your tank “surgery” and lay the tank on its side on a towel to prevent scratching the porcelain. Take the opportunity to use a good cleaner/degreaser product to scrub any gunk from the area between the tank and bowl, which will contribute to a better seal with your new gasket. Use a screwdriver to pry off the old gasket, and scrub that area clean as well.

Next, use a pair of Channellock pliers to unscrew the nut that holds the old flush valve in place. Then, use the pliers to unscrew the nut that mounts the flush handle to the wall of the tank—this unscrews clockwise.

Disassemble the One2Flush valve by giving it a 1/4 turn, which separates the valve body from the base. Remove the nut from the base. Place the base inside the tank, with its threaded end protruding through the hole in the bottom of the tank and protected from the inside with the included rubber gasket. On the underside of the tank, install the O-ring and spin on the nut to secure it in place. Place the new tank-to-bowl gasket over the nut and reinstall the tank.

From inside the tank, install the valve body in the base by simply aligning the two tabs on the bottom of the valve and twisting it tight.

Just add the handle, and that’s all it takes for the flush valve installation. The toilet is ready for action, and the valve is adjustable once installed so you can dial in your desired flushing action once everything is in place.

HydroRight Dual Flush Conversion Kit

One installation advantage of the HydroRight system, from MJSI Inc., is that you may not have to remove the tank at all. The HyrdoRight dual flush valve replaces the flapper, installing directly over the overflow tube of your existing flush valve.

To install, first shut off the water supply and drain the tank as explained earlier. Remove the flapper in the bottom of the tank and remove the flush handle and the chain that connects it to the flapper. Disassemble the flush valve with a quarter turn, which separates the valve body from the base. Slide the clamp of the base down over the old overflow tube, seating the blue silicone gasket into the flush valve opening. If there’s a gap between the clamp and the overflow tube, use the cam adjuster (small plastic sleeve included with the kit) to tighten the fit. Next, slide the black rubber ring over the tube. Secure everything in place by pulling tightly on the zip tie that comes equipped on the clamp.

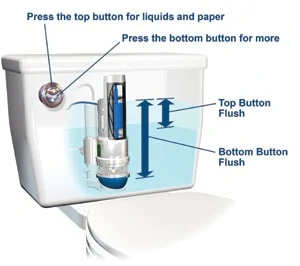

Rather than a flush handle, the HyroRight system utilizes a button mechanism to operate its dual flush feature. It’s easy to install by screwing on a nut to hold it on the tank and then connecting it to the button cable with a quick-clamp feature.

Once installed, the flush valve can easily be adjusted to your desired flush volume by moving either the green or blue slide on the valve body. The green slide adjusts the full flush, and the blue slide adjusts the smaller, water-saving quick flush.

As with our previous toilet, we were again replacing a ballcock valve, so we upgraded to a cup-style fill valve, in this case the HydroClean 660. This easy-to-install fill valve is adjustable, so it conserves how much water is sent to the tank and bowl upon refill, reducing the water that drains down the bowl by as much as 36 percent. The 660 model also includes a pipeline full of cleaning jets that actually cleans the inside of the tank with each flush, preventing the murky discoloration and sediment that often accumulates within the tank and contributes to seal failure and water leaks.

Final Thoughts

We were impressed with the water-saving performance of the One2Flush, and after extended usage we found it had a notable performance advantage over the HydroRight. Both are intended to save thousands of gallons each year, reduce water/sewer bills and conserve resources in drought-stricken areas where water usage is limited. However, the HydroRight had trouble achieving an adequate fill for the quick flush, often requiring two flushes, which defeated its purpose.

The HydroRight’s unique push-button method enables you to press a small button for the quick flush and a larger button for the full flush. It works fine, but the design of the mechanism means you won’t be able to swap it for a different handle if you aren’t happy with the look of the button design.

The One2Flush uses a more conventional lever-style handle, in which you flip it to the left for a small flush, to the right for a large flush. We did notice that when a toilet lid is left open it can hold the lever ajar and keep the toilet running. Fix this by closing the lid. According to women around the world, that should be standard procedure anyway.