Decks are some of the most popular homeowner projects.

They can be a small extension off a family room, bedroom, or dining area or an outdoor “room” large enough for parties. Decks can be elevated or built near the ground in single- or multiple-level designs. They can be simple projects for beginners or examples of expert craftsmanship.

If you’re new to deck building, understand the basics of deck construction. Then, dive into the details as you tackle each project phase.

Read on for the best information about deck-building basics.

Planning Your Deck

To arrive at the best design, consider how you’ll use the deck. Will you host large parties, or do you want a quiet place to relax? Are you seeking sunshine or shade, privacy, or a wide-open view? Does a ramp for wheelchairs make sense? How will you landscape the area around the deck? To get ideas and design inspiration, walk around your neighborhood to see how others handled their deck designs.

When you’re ready to build, here’s how to start:

- Mark the perimeter of the proposed deck using small stakes;

- Call or make an online request to have the building’s utilities marked for you. It’s usually a free service for homeowners;

- Contact the local building authorities to see the required permits and limitations. Some communities may restrict the size and height of the deck or require the use of specific materials;

- Determine the basic design of the deck, including the size and placement of posts, beams, and joists;

- Prepare a materials list and

- Submit your plans for review and ask for a building permit.

Materials Required

Decks must be constructed of long-lasting, moisture-, rot-, decay- and insect-resistant materials. Three basic types of materials can be used.

First, there are naturally insect- and moisture-resistant woods such as redwood and Western Red Cedar, which contain natural compounds called “thujaplicins” that act as preservatives. As a result, the wood will have a long life and need less chemical treatment. In addition, cedar’s even, uniform grain and low density make it less likely to swell, warp, cup, or twist compared to other soft and hardwoods. Cedar is also free of the pitch and resin found in other softwoods – a quality that makes it ideal for a wide range of finishes, whether you choose a lightly tinted semi-transparent stain or a two-coat solid color finish.

Second, pressure-treated woods with chemical preservatives, such as Wolmanized Natural Select, are readily available, inexpensive, and easy to work with. Pressure-treated lumber is the most widely used material for outdoor structures. For more information, visit www.wolmanizedwood.com.

Last, composite decking materials made from a combination of plastic and wood fibers can provide a low-maintenance alternative to real wood.

Availability, cost, the final design of the deck, and your personal preferences will determine which materials to use. Check with your local building supply dealers to see what materials are available in your area.

Designing Your Deck

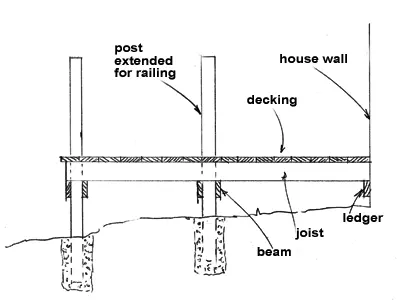

Regardless of how high or low, big or small, a deck consists of several basic parts:

- Footings

- Posts

- Beams

- Joists

- Decking

- Railings

- Steps

The size and spacing of the different members depend on the design of the deck and the woods being used. The charts at the bottom of this article show the spacing for non-stress-graded redwood (Construction Heart) lumber and for Wolmanized Natural Select Pressure Treated lumber.

Laying Out the Deck

It is important that the layout of the deck itself be square and that it be square to the building that anchors it. Even if some portions are free-form or curved, the basic support structure must be square (in the horizontal plane) and plumb (in the vertical plane).

The first step is to determine the height of the deck by measuring the distance between your established grade line and the house floor at the doorway. Allow a 2- to 4-inch step-down from the house floor to the deck so water won’t flow into the building. Next, drive a stake to indicate one side of the deck’s length. Then, pull a string from the house to create a level line and tie the end to the stake. Do the same on the other side to locate the second corner stake, making sure the distances are equal. Then, measure the distance between the two strings and move the stakes so that the strings are perfectly parallel, maintaining the same distance from one another along their entire length. This provides the basic deck shape.

Drive more stakes about 2 feet on either side of the first ones and construct batter boards. Before securing the batter boards to the stakes, extend string lines across to the batter board tops and make sure that the tops are level with the string positions on the house and level with each other.

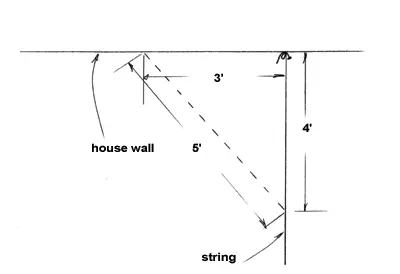

Above: Use the right triangle method and string lines with batter boards for laying out the deck., locating the support posts, and ensuring the deck support structure is square.

Use the math of right triangles to ensure that the shape outlined by the stakes and strings is square. First, measure 3 feet from the building along the string and mark the distance with a felt tip pen. Then, measure 4 feet along the building wall and mark that distance. Last, measure diagonally between the two marks. The distance must be 5 feet to create a truly square corner. Move the string line extending from the house in or out to achieve the correct measurement. When you’ve found it, tie the string to the batter board, making sure it’s still level. Square the opposite side of the deck the same way.

Repeat the procedure twice more to make the deck’s far edge square to both sides. With those two corners square, remove the stakes and relocate them directly underneath the point where the strings intersect. This establishes the outside corners. To verify that the shape is truly square, measure the outlined deck diagonally from each corner stake to each deck corner at the house. The two distances should be equal.

To prevent weeds from growing up through the deck, cover the area below the deck with black polyethylene film or landscape fabric and spread rock or mulch over it.

Deck Construction

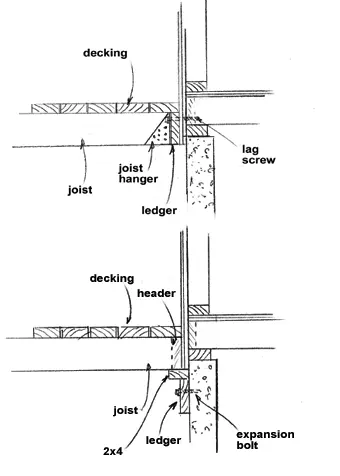

The first step is installing the ledger board, where the deck connects to the building.

Position the ledger board against the house, ensuring it is set low enough for the decking boards to reach the correct final height at the house threshold.

With the help of an assistant or using braces, hold the ledger board level and nail it in place at both ends. Then add appropriate fasteners to anchor the ledger firmly to the house using washers and 3⁄8-inch lag bolts or construction screws that extend at least 2 inches beyond the thickness of the ledger into the structure, not just the house’s brick veneer or its sheathing. For masonry walls, use appropriate masonry anchors.

Because the ledger is a key structural element, it must be protected from water with flashing. More builders now use flashing tape, an upgrade from traditional ledger flashing. Trex Seal ledger flashing tape is an 11-inch-wide waterproofing tape that includes a flexible aluminum core and a double-release backing. Those features eliminate any possible mess and make it easier to conform the tape to the ledger board’s inside corner, guaranteeing a tight seal. The company also offers a 22-inch-wide sub-ledger flashing tape that prevents water from seeping into or past the ledger board from behind.

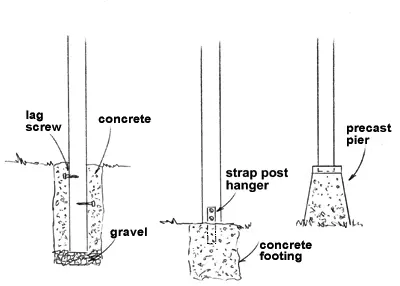

Footings are required to support the posts. These might be concrete blocks, pre-cast pier blocks, or poured concrete supports. Footings are usually twice the diameter of the post they support. Consult the local building code to determine what types and sizes of footings are allowed. Whatever you select, the footings should extend below the frost line. In most soils and locations, this will be 2 feet deep. The tops of the footings should be above grade to prevent water from pooling around the posts. If you’re using pressure-treated wood posts, set the posts into holes on a layer of concrete and then a layer of gravel. Quikrete recommends pouring its dry concrete mix into the hole and around the post until it is 3 to 4 inches from the top. Then, pour in water (1 gallon per 50-pound bag of concrete) and fill the remainder of the hole with soil. Wait at least 4 hours before placing heavy objects on or against the post.

Ready-made pier footings are available, but it’s not difficult to pour your own concrete footings, either directly into the holes or into tubular cardboard forms. If you don’t sink the posts, they must be anchored to above-grade footings using metal brackets, such as those from Simpson Strong-Tie. Whatever your method for anchoring the posts, make sure they are correctly sited, plumb, and remain square to the structure. While waiting for the concrete to set up, use stakes and braces to keep the posts from moving.

To site the beams, pull a level string from the top of the house ledger board to the posts. To fasten the beams, you can cut the posts and place them on top or, if you want to use the posts to support railings, leave them tall and attach the beam to the sides.

Next, fasten the joists to the beam and ledger board. Most people use metal joist hangers, but you can also set the joists on top of the ledger board and outer beam. However, this requires adding a fascia board or rim joist to cover the ends of the exposed joists. Either way, space the joists according to the decking you chose. Spacing of 16 or 24 inches on center is the most common, but some decking could require 12-inch spacing. To prolong the life of the joists, apply joist flashing tape, such as Trex Protect, to their exposed tops before you put down the decking.

If you have an elevated or two-story deck, consider using the space below for storage or as living space. For what you can gain, the additional time and money required can be worthwhile. To keep the job simple, use an off-the-shelf kit, such as Trex RainEscape. It’s an over-the-joist deck drainage system that uses flexible trough-shaped barriers to keep the joists, fasteners, and everything else below them dry. With this system in place, it’s easy to install lights, ceiling fans, and other accessories to serve the room below without worrying about water infiltration. In fact, you can use the water flowing off the deck to water your lawn or rain garden.

Installing the Decking

Decking can be 2-by-4 or 2-by-6 lumber or 5/4 boards. Install the first deck board on the house side of the deck, leaving a small gap for expansion. This board will serve as a guide for the next deck boards. Traditionally, deck boards have been installed “bark-side” up to reduce the cupping of the board edges. But if the other face of the board is better, install that side up instead. The fasteners (screws are best) should have a galvanized or other corrosion-resistant coating or be made of stainless steel. Some woods need to be predrilled to prevent the fasteners from splitting them, especially near the ends. Hidden fasteners are another option. They’re mostly used with composite decking and wood deck boards with side grooves.

Install deck boards straight or diagonally and in herringbone or parquet style. In each case, however, stagger the butt joints to fall on different joists. Notch the deck boards as needed to fit them around any posts. At the edge of the deck, let the boards run ragged, and once you’re done, snap a chalk line and use a circular saw to cut all the boards to the correct length. If warped or crooked boards give you trouble, try using a Hardwood Wrench or a Hardwood Wrench, Jr. to lever them into position for fastening.

Deck Finishing Details

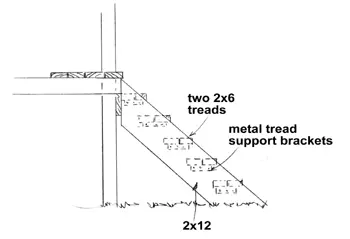

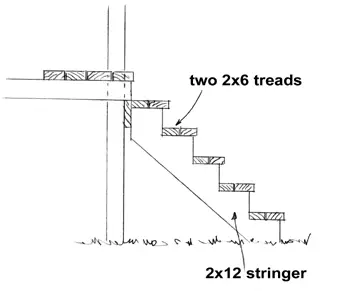

Steps connect the deck to ground level or from one deck level to another. You can support the treads using a traditional notched stringer or opt for a solid stringer and use metal brackets, such as Strong-Tie Staircase Angles. Both make it easy to adjust the angle of the stringers to span the distance from the deck to the ground.

Start by measuring the rise (vertical height) from grade to the top of the deck. Divide that measurement by 7 inches or whatever stair rise you prefer. The result tells you how many stair risers are required. To determine the total run of the stairs, multiply the number of steps required by 11 1⁄4 inches. Cut the 2-by-10 stair stringers and fasten them to the deck framing with a Strong-Tie Framing Angle. Mark the staircase angle support position on both stringers. Install the Staircase Angles using the manufacturer-recommended fasteners, and then install the stair treads. Stairs of more than three steps should have handrails on each side.

For safety, railings will also be required on the deck perimeter if your deck is more than 24 inches above grade. In the past, railings tended to be straight wood pieces. Railings are the most prominent elements of most decks, and today, you’ll find a number of modular railing designs available in wood, metal, and synthetic construction.

Composite Decking

Composite deck materials, including deck boards, rails, and balusters, are installed somewhat differently than wood but use the same structural elements. The main difference is in the fastening and layout schemes. Otherwise, most posts and rails from the major manufacturers come as a “system.” Just follow the manufacturer’s instructions, and you’ll have no trouble.

Here are the basics:

- Assemble the post bracket and fasten it to the rim joists.

- Insert posts into the brackets and connect them with the appropriate fasteners.

- Install the deck boards, cutting them to fit around the posts and leaving a 1/8-inch gap.

- For a more decorative look, add a post collar over the post.

Next, measure and cut the universal support rails and the decorative handrail. Attach them with the brackets supplied. Add support blocks to match the balusters for extra strength. Next, insert the end balusters/spindles tight against the posts, and then insert the balusters and fillets to space them properly. Fasten everything in place with stainless steel fasteners. Fillet spacer blocks may also be glued in place. Then install the decorative handrail and cut the post tops to the correct size if you haven’t already. Install the post caps.

Install stair railings similarly, but because they’re angled, take additional care in measuring, cutting, and fitting them. Start by anchoring the stair stringers, then install the decking material for the steps. Use mitered corners for the treads to conceal the cut ends. Next, install the universal stair rails, followed by the balusters, fillets, decorative handrails, and post caps.