Making Christmas presents in your shop for family and friends triples the fun. You have the pleasure of woodworking and the pleasure of giving hand-made gifts, and the receiver will appreciate the thought and effort that goes into a hand-made object. If you’re into making a little money with your shop, these “gifts” also make great projects to sell at craft shows and fairs. Following are gifts for young and old, male and female.

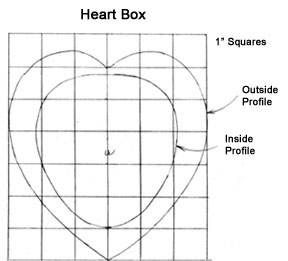

Heart Jewelry Box

Any lady, young or old, will appreciate this heartfelt gift. Although it looks simple, the box takes a bit of expertise. The box shown was made of walnut, but any tight-grained hardwood will work. The body of the box is made of 1-1/2-inch thick material. Bowl-turning squares, or blocks in the size shown, are available from a number of mail-order companies. You will also need 3/4-inch thick pieces for the top and bottom.

The inside profile is cut first, using a drill bit to create starting holes. Then a jigsaw is used to make the cut-out.

The box is actually assembled from three pieces; a body, bottom and top. The first step is to enlarge the squared drawing and make a pattern for both the inside and outside of the box. The pattern for the outside will also be used for the bottom and top. Mark both the inside and outside cuts on the wood blank and cut the inside first. Make starting holes at the top and bottom of the profile, and use a jigsaw with a long blade to make the cut-out. Rasp or sand as needed. Once the inside is cut, cut the outside using a bandsaw or a jigsaw with the stock clamped to the edge of a workbench or other solid surface. Sand the outside of the box smooth, then use it as a pattern to create the bottom. Cut the bottom piece to shape and sand smooth. Glue the bottom in place and again sand the outside edges smooth.

A spindle shaper smoothes the inside.

Use the glued-up box to mark a pattern for the top. Remember to turn the box upside down on the top piece and mark the bottom side of the piece. Rout the top of the lid using a router in a router table to create a rounded profile. Apply finish to both the inside and outside of the box, as well as to the lid. Three coats of semi-gloss polyurethane were applied to the box shown, smoothing with steel wool between coats. The inside should have felt applied. Felt, available in craft stores, is cut to fit and glued in place using craft glue.

An alternative method, and somewhat easier, especially if you’re building more than one box, is to use spray-on flocking. Available in a kit, the adhesive is applied, and then the powdered flocking. Once the inside has been covered, mortise tiny brass hinges in place on the back of the box and lid.

Materials List

Body, 1-1/2 x 6 x 6-1/2”

Bottom, 3/4 x 6 x 6-1/2”

Lid, 3/4 x 6 x 6-1/2”

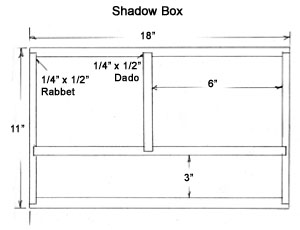

Shadow Box

One of the simplest projects, but well appreciated by “collectors” is a shadow box. Shown are a couple of examples, but you can vary the sizes and dividers to suit a particular collection. The walnut box is assembled from 1/2-inch stock, has an open back and is the easiest to build. It can be hung vertical or horizontal, depending on the collectibles. First step is to plane the stock to thickness, or purchase 1/2-inch stock. Rip the stock to width and joint both edges. The box is glued together using half-lap and dado joints for strength. The joints can be cut by hand using a backsaw and chisel, or cut with a dado head. Apply TiteBond glue to the joints and clamp the assembly together all at one time. Make sure the assembly is square, then clean off all excess glue with a damp rag, paying special attention to the inside corners. Once the glue has dried, sand all surfaces and apply finish. Again, polyurethane was used. Attach picture-frame hangers to the back. You’ll need one for a vertical and two for a horizontal hanging.

Materials List

Top and Bottom, 1/2 x 3 x 18”, 2 req’d.

Sides, 1/2 x 3 x 10-1/2”, 2 req’d.

Horizontal divider, 1/2 x 3 x 17-1/2”, 1 req’d.

Vertical divider, 1/2 x 3 x 6”, 1 req’d.

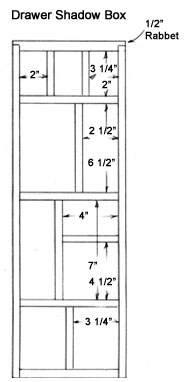

Drawer-Box

One neat way of creating a shadow box is to install dividers in an old drawer, recycling it into a wall hanging. The box shown is actually assembled to look like a drawer, and standard drawer construction is used for the “box.” First step is to rip the pieces to the correct width and joint or sand all edges smooth. Note the sides are 1/2-inch, and the front or “top” is 3/4 inch. Cut 1/4-by-1/4-inch dadoes, up 1/4-inch from the bottom edge in the front (top) and sides to accept a 1/4-inch back. Cut a back piece of 1/4-inch stock to size and cut a drawer back (box bottom) to size. Fasten the drawer front and back to the sides with glue and brads. Slide the drawer bottom in place, use a carpenter’s square to make sure the box is square, then fasten the 1/4-inch bottom to the back with brads. Now you have a basic drawer. Cut the dividers as desired and hot-glue them in place. Then add strength by driving brads in from the back into the dividers. Sand and finish, then add a drawer knob and hanger.

Materials List

Top, 3/4 x 2 x 8”, 1 req’d.

Bottom, 1/2 x 1-1/2 x 7”, 1 req’d.

Sides, 1/2 x 2 x 23-3/4”, 2 req’d.

Back, 1/4 x 7-1/2 x 23-3/4”, 1 req’d

Dividers, 1/2 x 2 x 60”, cut to fit Serving Tray

Serving Tray

A decorative serving tray is another handy and attractive gift. The tray shown is uniquely assembled from both walnut and red oak, using screws and walnut plugs over the screws as a decorative touch. The entire tray is assembled from 1/2-inch stock.

Stock is run down to 1/2″ thick on a planer, then glued and clamped together using Titebond II waterproof glue.

The first step is to plane the stock to the correct width using a surface planer. The bottom is assembled using biscuits and TiteBond II waterproof glue. Cut the biscuit slots, and then glue the assembly together, making sure it is clamped squarely and not warped. Once the glue has dried, belt-sand the joints smooth and cut the ends square.

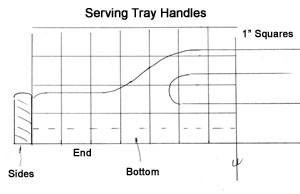

Enlarge the squared drawing for the ends and bandsaw their top edges to shape. Mark the cut-outs for the handles. Bore starting holes in each end of the handle holes, and then make the cuts with a jigsaw. Sand all edges smooth, and round the inside of the handles and the top edges with a router. Attach the end pieces to the bottom by first locating the screw holes. Use a forstner bit to countersink 1/4-inch deep for the wood plugs, and then use a 1/8-inch drill bit to drill through the holes. Apply TiteBond II glue to the bottom ends and clamp them in place. Drill starter holes through the end screw holes into the bottom ends, and then drive screws in place. Cut the sides and attach to the sides of the bottom in the same manner. Attach the upper ends of the sides to the upper ends of the end pieces. Wipe away all excess glue and allow the glue to set.

The surfaces are belt-sanded flat and smooth.

Using a plug cutter in a drill press, cut the walnut plugs. Glue the plugs in place in the holes and sand their tops flush with the surrounding wood surfaces. Sand the entire tray thoroughly, and then apply salad bowl finish.

The ends and hand holes are cut to shape, then sanded smooth with a spindle sander.

Materials List

Bottom, 1/2 x 14 x 18”, 1 req’d.

Ends, 1/2 x 3-1/4 x 14”, 2 req’d.

Sides, 1/2 x 1-3/4 x 18”, 2 req’d.

Basket Bench

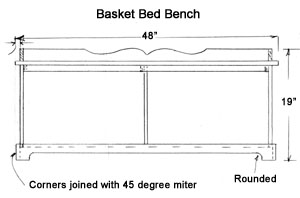

The storage bench shown utilizes a pair of baskets for storage and offers seating as well. Although a larger project, it is one of the simplest and came about when my wife Joan admired a similar piece in a furniture store as an end-of-the-bed bench. I modified the design somewhat to suit the bedroom. The bench can also be used in just about any other room, providing seating and storage for any number of items.

The bench is made from stock 1 x 12 pine shelving, using a biscuit joiner and gluing up the wide pieces with biscuits.

Make sure the pieces are clamped square and flat.

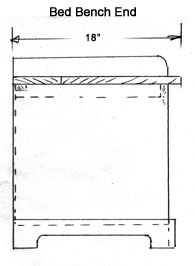

The first step is to acquire the baskets so you can size the bench to the baskets. The bench is made from stock 1-by-12 shelving material found at our local Lowe’s store. The biggest chore is gluing up the wide pieces for the top, bottom and sides. Again, a biscuit joiner and biscuits were used for this chore. A full-width piece and a piece ripped to size were used for creating the wide pieces. After ripping the narrow pieces all edges are smoothed on a jointer. Then the wide stock is glued up and clamped. It’s extremely important to make sure the stock is not warped during the clamping steps. Once the glue has dried, the surfaces are belt-sanded to smooth the joints, then sanded with progressively finer grits of sandpaper. Cut rabbets in the back inside edges of the sides and top for the 1/4-inch back.

After the glue has set, the pieces are sanded smooth with a belt sander, followed by an orbital sander.

The cabinet is assembled with an air nailer, staples and finish brads.

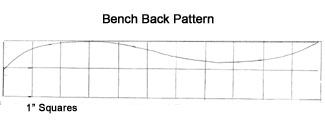

Assembly begins by attaching the ends to the bottom. An air gun with staples was used for this chore. The back and front supports are ripped to width and fastened in place. The back is fastened inside the rear rabbets, overlapping the back support. Then the center divider is cut with notches in top and bottom for the back and front supports and fastened in place. Add the cleats. Enlarge the squared drawing for the support legs, transfer to the stock and cut to shape. Sand smooth and attach with No. 6 finish nails set below the surface, and the holes filled with wood putty. Cut the top piece to size, and then cut the back piece and fronts of the ends using a bandsaw. Sand smooth and attach to the top with screws from the underside.

The scrolled top is cut with a jigsaw.

Finally, assemble the bench, fastening the top to the case.

Materials List

Top, 3/4 x 18 x 48”, 1 req’d.

Bottom, 3/4 x 16-1/2 x 44-1/2”, 1 req’d.

Ends, 3/4 x 14 x 16-1/2”, 2 req’d.

Center Divider, 3/4 x 13 1/4 x 16-1/4”, 1 req’d.

Back 1/4 x 14 x 45”, 1 req’d.

Cleats, 3/4 x 1-1/2 x 15-1/2”, 3 req’d.

Back and Front Supports, 3/4 x 1-1/2 x 44-1/2”, 2 req’d.

Front leg, 3/4 x 3 x 47-1/2”, 1 req’d

Side Legs, 3/4 x 3 x 17-1/4”, 2 req’d.

Top back, 3/4 x 2 x 46”, 1 req’d