By Myron R. Ferguson

Tray Ceilings Enhance Ordinary Ceiling Lines to Create Architectural Interest.

Quite often when I mention a tray ceiling to a prospective customer, I find myself quickly explaining that it is not what they think. The project is actually quite simple. Tray ceilings are generally considered by homeowners to be complicated, expensive and time-consuming to build. As a drywall contractor that specializes in decorative drywall work, I build a lot of tray ceilings because they are fast, easy to construct and come out perfect.

I don’t just meet my customers’ expectations, I exceed them.

A “tray ceiling” is a common term for a recessed ceiling, often with the recessed sides sloped at an angle. The original flat ceiling has its edges lowered to create the center recess area. The lowered edges vary in width according to the dimensions of the room. The basic purpose of a tray ceiling is to break up an ordinary flat ceiling line and add a variation in height to create architectural interest. A feeling of spaciousness can be created by the look of the different levels, and a tray ceiling can make a low ceiling look higher.

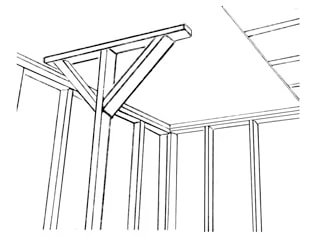

Creating the Recess

The entire ceiling should have drywall attached before the tray construction starts. First, determine the width of the lowered area of the ceiling. This varies based on the size of the room and is typically 12 to 24 in. wide. Mark off the layout by snapping chalk lines to use as an installation guide.

Next, attach furring strips to the ceiling along the wall and inner edge. The furring is 1-1/2-in. thick and should be fastened to the solid framing behind the drywall. Glue and screws are used to secure the furring.

Attach 1/2-in. thick drywall to the furring using standard drywall installation techniques. Ceiling panels can be installed with the help of an assistant and a homemade 2×4 T-support (also called a “deadman”). When working alone, you may need to rent a cradle lift, a device that rolls on casters and safely lifts panels as high as 11 ft.

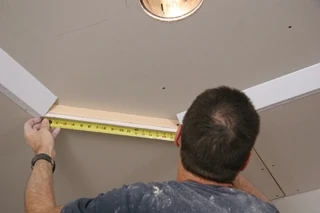

The next step is to attach the EZ-Tray bead. The EZ-Tray, available from Trim-Tex (www.trim-tex.com) is a 3-inch wide, chamfer-edged layering bead specifically designed to make a tray ceiling. Snap chalk lines to guide placement of the bead, and staple it in place along the mud leg of the bead. Attaching the bead to the snapped lines helps ensure straight looking edges.

Attach the longer pieces first. The edge that fits against the upper ceiling should have adhesive caulk applied to hold it tight against the drywall. After sanding and priming, this upper edge gets caulked again to create a perfect transition edge.

The mitered joints can be cut to fit with tin snips. Mark the angle with the miter marker that comes with the EZ-Tray. Both edges in the corners can be mitered, but it is easier to attach the first piece with a square cut. Then, miter the abutting edge.

Finishing Moves

Tape all the seams and inside corners on the drywall and conceal with joint compound. Conceal the mud edge of the EZ-Tray bead with two or three coats of joint compound. Then, sand and apply a coat of primer. After priming, applying more caulk along the upper edge of the tray angle may be necessary for a more perfect transition.

The right paint color can greatly enhance a tray ceiling. For instance, a recessed tray ceiling can be painted a few shades darker than the main ceiling color to make it appear even more recessed and to provide a stronger contrast to the look.

Time and Cost

The time investment for this tray ceiling project took less than a single work day for a master bedroom, measuring 14 by 15 ft. Installing the furring strips, hanging the drywall, attaching the EZ-Tray, applying the compound and sanding took about 6-1/2 hours.

Material cost was $95. I used seven 8-ft. 2×4’s for furring ($21) and mostly scrap drywall equivalent to about 120 sq. ft. (cost $30). The beads cost $44, including 60 ft. of chamfer stop for the narrow strip along the wall angle, as well as five 10-ft. pieces of EZ-Tray. When I provide an estimate for a tray ceiling, I typically charge about $12.00 per linear ft., so a 14-by-15-ft. room (58 ft. x $12) would go for $696.

SIDE NOTE 1

Installing Ceiling Panels

When hanging drywall, you’ll need to work with a partner to hoist the large, heavy sheets in place. For ceilings, using a stepladder, scaffold or a “deadman” will make hanging ceiling panels a lot easier. A deadman is a temporary brace in the shape of a “T,” built from 2×3 or 2×4 stock. Build the brace as high as the ceiling and wedge it in place, using the top “T” bar to hold panels in place until they can be fastened securely.

SIDE NOTE 2

Further Cost Savings

Not only are these ceilings easy to build, but the cost of the materials can be greatly reduced by using scrap drywall and lumber. The recessed edge of the ceiling is usually less than 24 inches wide and drywall contractors always have plenty of scrap pieces of drywall that size leftover from construction sites. If you are using new drywall, there is no need to handle big sheets. Cut them to size for easy lifting. The wood used to fur the ceiling down can be scrap lumber left around most jobsites, or just purchase 2×2 material.