Organize your work space with a Sturdy Storage Rack for Sheet goods.

By Matt Weber

My workshop is a detached two-car garage that serves as my laboratory for all things related to Extreme How-To, from photo shoots and material storage to pre-fab work and project prep.

I try to keep the place organized, but the work space goes through cycles of relative order and total chaos. During one of the recent chaotic episodes I got fed up with the various sheet goods that littered my shop, obscuring sight of tools and supplies and generally obstructing my passage from Point A to Point B. I had planned for years to build a storage rack to solve this problem and finally found the motivation to do so.

What I did not find was a plan to build a storage rack that fit my needs. Sure, you’ll find a variety of woodworking plans online, but most of these storage units are very large and often designed for a great deal of capacity. While many of the plans I found would work wonderfully for a full-fledged woodworking shop, I’m not a full-fledged woodworker. I’m more of a jack-of-all-trades (master of none) DIY guy who usually has a half dozen various sheets floating around, so I did not need a monster rack to hold dozens of sheets. Not only would the extra storage space go largely unused, but the large size of the “pro” racks would pose a new problem in my cramped shop by occupying square footage that I could put to better use.

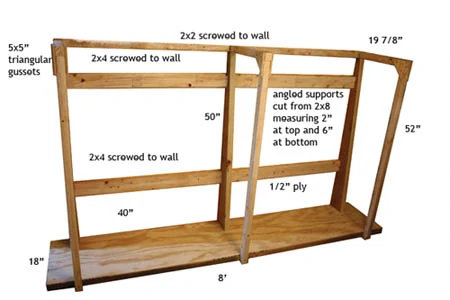

After a few hours of research, I decided to get creative. The rack shown in this article is my own reation, a concept that I cobbled together from a few other rack/shelf designs. My design provides enough storage for my materials, keeps the supplies against the wall and out of my way, and even has an upper shelf for further storage of long items like 2x4s and pipe clamps. If you’re a part-time carpenter or hobbyist woodworker, then maybe this rack will suit your needs as well.

Location

You will need probably 9 or 10 feet of available wall space for placement of the rack. However, the sheets go in and out of the end of the rack, meaning that you will need clearance at one end or the other to insert or retrieve the sheets, bearing in mind that a full sheet is 8 feet long.

My solution was to install the rack next to the shop’s entryway. Since I could not block the doorway with another stationary shelf or cabinet without impeding my entrance to the shop, this was an area of “dead” space whenever the door was not in use. The doorway was located at the corner of my shop and adjacent to an overhead garage door. So, whenever I need to pull out a sheet that is larger than the 5 or 6 feet of clearance at the end of the rack, I can simply lift the overhead door to gain more room. This seemed to me the most logical way to economize space, and you should plan accordingly when locating the rack in your shop.

Mounting

The rack is stationary and mounted to the wall of my shop to provide plenty of strength and stability to hold the heavy sheets. My shop is a wood-framed building with the interior walls sheathed in plywood. The rack’s cross-braces that are installed against the wall are fastened into the solid stud framing with 3-in. screws.

If you are installing the rack on a block or concrete wall, then use the appropriate wall anchors or concrete screws to mount the rack.

Angled Supports

The rack shown is designed with three angled supports for the sheet goods. The angle keeps sheets tilted backward and stable, while providing solid support so the sheets do not bend or bow.

I cut the angled supports from 2×8’s using a circular saw, and each one measures 50 inches long. The top end of the support is 2 inches wide while the bottom is 6 inches wide. I marked these measurements on each board and snapped a chalk line to guide the cut. I then ripped the angle with a circular saw.

To make the most of your materials, I recommend cutting the angled supports first and then using the cut-off pieces as blocking for the floor of the rack. FloorThe rack rests on a raised plywood floor. The plywood is a smoother surface than the diamond-tread flooring I have on the shop floor, which makes it easier to slide the sheets in and out. Raising the floor helps prevent damaging the edge of the sheets when pulling them in and out, plus it protects the materials from liquid in case of spills on the floor.

For the floor I used 1/2-in. plywood at its full 8-ft. length and ripped to 18 inches wide. After installing the supports, this width affords 12 inches of space for the sheets. The thickest sheet goods measure 3/4 inch, meaning I could feasibly store almost 16 sheets on edge with this size of rack, which is more than I ever have on hand. You can, however, customize the dimensions of the rack to accommodate whatever you need.

Any nominal 2x stock will work as blocking to raise the floor. As mentioned, I used the scrap cut-off sections from the angled supports. The idea is to have solid blocking beneath the floor to prevent it from bowing or dipping. I arranged the blocking flush with the perimeter of the plywood for a finished appearance and then fastened the floor onto the blocking with countersunk drywall screws.

Fill the recessed screw heads in the floor with wood putty and then sand them smooth. This will eliminate holes in the floor that can snag the corner of a sheet.

Sheet Support

To assemble the components that will support the sheet goods, first locate one of the angled supports at the center of the floor with the square side facing the wall. The 6-in. end rests on the floor with the 2-in. end at the top. The back of the support should be plumb and flush with the wall.

I located the other two angled supports on either side of the center support, spaced 40 inches apart. I then square-cut 2×4 stock into four 40-in. pieces to serve as cross-braces.

To mount the lower horizontal cross-braces, I supported them temporarily with a scrap 12-in. block as I leveled them between the angled supports. Once in position I sank 3-in. deck screws through the cross-braces into solid stud framing.

I installed the second set of cross-braces in similar fashion, mounting them level between the supports approximately 2 feet above the lower braces.

Until this point the angled supports had been standing loose and unfastened. Once the cross-braces were secured, I fastened the angled supports to them by driving screws through the sides of the supports and into the end-grain of the braces. (Note: You will actually have to install either the left or right cross-braces first, fasten the center support, and then install the cross-braces on the other side. Otherwise, the braces block access of your drill/driver to the center support).

Retainer Brackets

At this point the rack offers support for full 4×8 sheets tilted back at an angle. To browse the sheet inventory I needed to be able to “page” through the sheets. However, to tilt the heavy sheets forward is to invite them to fall to the floor and off the rack, thus I needed a type of rail to keep the sheets contained on the rack.

I used three L-shaped brackets mounted to the tops of the angled supports and fastened to the front of the rack floor. To make the L-brackets, I ripped 2×4’s into 2×2 material. The top piece of each bracket should measure the width of the floor plus the width of your nominal 2×2. In my case, this meant the top pieces of the L-brackets measured about 19-7/8 in. The long, vertical legs of the L-brackets should measure the length of the angled supports plus the height of the rack floor (52 inches).

I preassembled the L-brackets prior to installing. The short piece of the brackets must be placed over the long pieces so they are supported from the floor.

I fastened the bracket first with a screw through the short piece driven into the end grain of the long piece.

I then strengthened the L-bracket joint with triangular gussets cut from some scrap 3/8-in. plywood. The gussets were cut on my table saw as right triangles measuring 5 inches on each square side. I cut six gussets and installed them on each side of the L-brackets, sandwiching the joint flush along the square edges. I fastened each gusset with a combination of wood screws and polyurethane glue to prevent movement.

Screw the L-brackets onto the top of the angled supports and into the front of the floor platform.

Be sure to use a level to check for plumb, and use a carpenter’s square to make sure the bottom of the brackets are aligned squarely with the angled supports.

Top Shelf

Although the rack will now hold sheet goods, you can enhance its storage capability by simply mounting a plywood shelf atop the sturdy 2×2 L-brackets. Additional 2×2 cross-braces will help support it. I ripped an 8-ft. sheet of plywood to 20 inches thick, which fit against the wall and flush over the tops of the brackets. I fastened it with wood screws into the 2×2’s. The top shelf gives the rack a more finished appearance, strengthens the entire structure, and provides more than 13 square feet of storage space.

When using the rack, I recommend stowing your full sheets against the angled supports to provide a large unbroken plane to lean all your other materials against, including plywood, drywall, plastic laminate, MDF, HDF or OSB. The rack’s top shelf then provides a perfect place to stow long boards and other materials that you’ll need for your next home-improvement project.