A Guide to Concrete Construction

By Monte Burch

Concrete floors are a major component of many buildings, from homes and garages to shops and sheds. Pouring a concrete floor is hard work, and it takes skill, strength and tools. You may wish to have this job done by a pro, but you can do it yourself. The tools can be rented at many rental places, and the skills are not very difficult to learn. If you’re undecided as to whether to do it yourself or have the job done by a professional, the following steps on pouring both a slab or in-foundation floor illustrate the basics and may help you decide.

A concrete slab on which a building is erected is a fairly simple concrete pour, but it takes more work in creating the forms needed to hold the concrete. A pour within a foundation requires little in the way of forming, but in some cases can be a bit more difficult to pour, especially on larger projects. Regardless of the type of pour, or whether you do it yourself or have the job done, the first step is to check with local building codes and regulations, and acquire any permits needed.

Creating a Slab

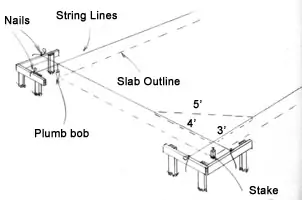

First step is to lay out the slab. Take your time with this step and make sure you get it right. Lay out the slab incorrectly, and the building can be a nightmare. The slab must be square. Mark the outline of the building with stakes at each approximate corner. Drive a nail into the top of the stake and, using a tape measure, measure diagonally from stake to stake. The measurements must be equal. Move the stakes in or out to create equal diagonal measurements.

Another method is to place string lines on the nails to mark a rectangular perimeter. Measure and mark 3 feet on one string and 4 feet on the adjoining line. The distance between these two marks should be 5 feet. Again, move in or out as needed.

After the corners are determined and the building laid out square, batter boards are used to create a permanent perimeter mark at all corners. These will stay in place until the forms for the slab have been constructed. Two-by-4 stakes are driven solidly in place and boards nailed to their outer edges. The batter board tops should be level with each other. A string line and string level or laser level can be used to make sure all boards are level with each other. Once the boards are established, a string line is run for all sides of the slab. A plumb bob is used on the intersection of the strings to position their crossing points, or the building corners, directly over the nails on the original stakes.

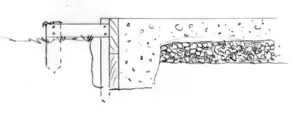

Mark the outline of the slab with lime, following the string lines. Then dig up the area and remove sod and debris. The area is normally recessed slightly, but the top of the slab must be well above ground level or fill level. In many instances the slab is raised and soil filled in around it to create a slope to drain rainwater away from the slab. In some instances local codes may require a footing be poured before the slab. In other cases, a “stiffener” method may be used, digging a deeper area below the frost line around the perimeter of the slab.

The entire area should be well compacted and of a uniform depth. Keep the ground slightly moist as well. The form is then constructed using 2-by-6’s. Stakes are driven into the ground on the back (outside) side of the forms every 3 or 4 feet apart to support the form boards. The stakes should be driven or cut off flush with the tops of the form boards. The stakes are fastened to the form boards using duplex nails or nails with double heads so they can be pulled out after the concrete sets. The forms must be level and at the proper grade or height. A carpenter’s level can be used for small projects, a string level for longer runs, but a builder’s or laser transit is best for larger pours.

A uniform grade is then established using fine gravel 1 to 2 inches deep. The best choice in gravel is called base rock. This has gravel and fine particles that pack down smooth. Once the gravel is in place, tamp it down smoothly.

If the pour is large you will need to divide it into smaller, easily worked sections using interior forms held in place with stakes. Pour one area, remove the forms and stakes and pour the second or third areas.

Floors should be reinforced according to local regulations. In the case shown, wire was used as reinforcement. Rebar may be used for slabs requiring more support. Garage floors are usually poured 4 to 6 inches thick.

You must also install all waste and supply lines for bathrooms, kitchens and so forth, leaving stub pipes. Close these pipes off to make sure nothing gets into them until you’re ready to connect them. In many instances you will also wish to install a plastic vapor barrier over the gravel.

Determining the Amount Needed

Concrete for a slab or floor is commonly ready-mixed and delivered in large trucks, although you can mix your own for very small jobs. Ready-mix concrete is sold by the cubic yard. To order the correct amount, tell the concrete supplier the width, length and thickness of the slab or floor you intend to pour. They will calculate the quantity needed, and in most instances supply slightly more than needed. You should have a place to dump a small amount of leftover concrete. They will normally add 5 to 10 percent for losses due to uneven subgrade, spillage and so forth.

Making the Pour

Concrete should not be poured on extremely hot, dry days as the material will dry out before it can cure properly. Concrete should also not be overworked. If the pour is overworked, too much water will be floated to the surface, which can cause scaling after the concrete dries. The material should be spread evenly and quickly once the pour begins, slightly overfilling the forms.

Pouring a floor—even a small floor—takes manpower. Pour when your best buddies are available and equip them with rubber boots, safety glasses and rakes. Once the pour has started, the liquid material should be evenly spread over the area using the rakes. Make sure all corners are filled. Leave the concrete slightly higher than the top edges of the form boards.

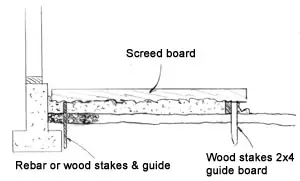

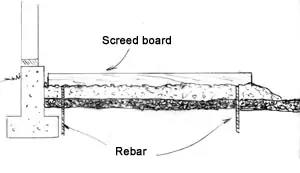

The next step is to use a screed board to drag off the excess concrete. The screed board is rested on the form boards and must extend past the form edges at least 3 inches on each side. Screeding is a two-man operation and at best is hard work on a large pour. Beginning on one end of the pour, place the screed board over the form boards with a person on each end of the board. Using a side-to-side motion, and at the same time pulling the board, sweep it across the form boards to the opposite end. Screeding levels the concrete with the tops of the form boards, pulling off excess concrete. Any low spots will be visible and should be immediately filled and the area rescreeded. A jitterbug or tamper should be used to settle the concrete and remove air pockets around the edges.

In standard construction, anchor bolts are needed to anchor the walls to the slab. These can be placed in holders nailed to the form edge, or pushed in place as the pour is made. The first method is more precise. The anchor bolts must always fall between the stud locations. If you locate one under a stud, you’ve got problems.

Floating and Edging

The third step is to float the surface, which will take away some of the roughness. This also helps fill any small voids and works the aggregate slightly below the surface. Do this immediately after screeding. A bull float is used for most floor pours. These are wide magnesium tools with a smooth flat surface, and handle extensions that can be used for a long reach. The float is pushed away from you across the surface with the rear edge slightly raised to prevent the float from digging into the concrete. The float is then pulled back at an almost flat angle. Once the float has been worked across one area, it’s moved to the adjoining area, and the steps repeated, slightly overlapping the first area edge. The Marshalltown RotaLeveler bull float bracket allows for easy and automatic changing of the float angle on the push and pull strokes.

The edges around the form boards should be separated using a pointing or margin trowel. Then use an edger around the top edge of the form. This creates a rounded edge that won’t chip off when the form is removed. The edger should be held fairly flat, but keep the front tilted up slightly when moving forward and the rear tilted up slightly when moving backward.

Troweling

The final finishing is troweling to smooth the concrete. Troweling provides a smooth, hard and slick surface, with the amount of smoothness depending on the amount of troweling, as well as the timing. Again, it’s easy to overwork an area. Small jobs can be hand troweled using a 14-by-4- or 16-by-4-inch finish trowel. It does take some skill to hand trowel a surface, especially a larger area. Troweling should begin when the sheen of water disappears and a footprint leaves less than 1/4 inch of depression. Several trowelings will result in a smoother, hard surface.

The first troweling is done with the blade held down flat on the surface. Use the trowel in an arc, overlapping each previous arc by about one-half inch. Allow the concrete to set slightly between trowelings. The final troweling should be done more vigorously and with the trowel tilted up slightly, pressing down with the edge. Concrete can set up quicker than you can hand trowel, so if you’re hand troweling, you may wish to enlist a buddy to help. A power trowel, available at most tool rentals, is the best choice for large slabs. In most instances floors are left hard and smoothed, not broomed, although you may prefer a light brooming in sheds and garages.

Keep the concrete damp for five to seven days after pouring. Do not allow it to dry out. Cover it with plastic sheeting and dampen down the surface every day or so.

Pouring an Inside Floor

Making a pour inside an existing foundation or walls is easier in some ways, because you don’t have to create the form, except to block off doorways. In other instances it’s a bit harder, because you may have to drag the materials further during the screeding process, say from the back of the building to the openings.

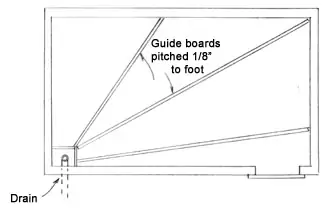

The subsoil surface should be prepared in the same manner as for a slab. In the instance of a floor inside a building that requires a drain pipe or sump-pump location, the drain pipe and drain must be installed and formed first as a separate pour. The floor must also be pitched to the drain in all directions, normally 1/8-inch to the foot.

Several methods can be used to establish the height and level surface of the pour. On small pours, such as a shed or single-car garage, experts often simply use 1/2-inch reinforcing rod cut into 2-foot lengths. These are spray-painted a bright fluorescent orange and driven into the subsoil at 3-foot intervals around the perimeter of the building and down through the center. The liquid concrete is poured to the approximate height of the rods, then screeded, pulling up rods as you screed past them. Using this method you can screed one side at a time as you make the pour, or screed one side, then go back, fill and screed the opposite side, but still making only one pour.

An alternative method, especially when using a vapor barrier, is to install screed guide boards on wooden stakes driven into the subsoil. The guide boards are created level or sloped to create the pitch desired. When making the pour, begin at the rear of the building and screed toward the door or openings, removing the guideboards and stakes as you go.

- Or, you can use wooden guide strips for the screed board.

Another method is to use 4-by-4’s as guide boards. Make sure the subsoil surface is flat, smooth and level (or at the correct pitch) and lay 4-by-4’s on the vapor barrier. Make the pour, again starting at the back and working toward the door, removing the 4-by-4’s as you go. Some like to leave the guideboards in place until the concrete just begins to set, then walk across it, remove the boards and fill in the spaces with fresh concrete. But this requires having enough fresh concrete on hand to fill in.

If the pour is fairly large, say a two-car garage, another method is to create three separate pours. Divide the building into thirds lengthwise and install guide boards on stakes. Make a side pour, make the opposite side pour, then remove the guide boards and make the center pour.

Wet down the foundation before starting the pour and be careful not to splash concrete up on the walls of the building during the pour. When you reach the door forming, smooth the opening edge with an edger and remove the form board.

Tips and Tricks

If making small pours, say for a shed, and mixing your own, a Crete Sheet, the world’s simplest concrete mixer, can be used to mix pre-mixed concrete. It easily and quickly mixes an entire 80-pound bag per use, but is a two-man operation. For more information, visit www.cretesheet.com.