Frame-and-panel doors are a tradition with many classic furniture styles as well as cabinets. Frame-and-panel doors offer several advantages including their beauty. But, more important, they are less prone to warp and twist than solid doors. With the inset panel “loose” in the frame, they more readily adjust to changing humidity, heat and cold conditions.

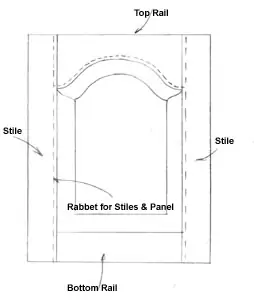

Frame-and-panel door parts.

Several techniques can be used to create frame-and-panel doors.

Although frame-and-panel doors appear complicated, they are not really hard to build if you take your time and measure carefully. Frame-and-panel doors consist of the rails (the top and bottom pieces), the stiles (the side pieces), and the panel. The panel may be flat or raised. Flat panels are the easiest to construct and install. Raised panels take more work, and arched raised panels require the most work. Arched panels may be simple arches, or a cathedral design.

One of the simplest doors uses a flat panel. In this case a piece of highly figured walnut has been resawn on a bandsaw to create “bookmatched” door panels.

Tools to Use

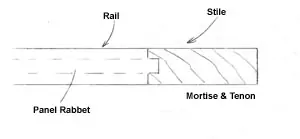

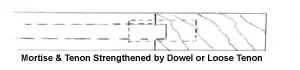

Several different techniques can be used to create the doors. Flat-panel doors can be built with hand-tools alone, in the traditional way. The rails and stiles are joined together with mortise and tenon joints. Hand cut the tenons with a backsaw and the mortises with brace and bit, and chisel. The rabbets for the panels can be cut with a hand-held rabbet plane.

Most of us, however, prefer to create the doors with power tools. Again mortise-and-tenon joinery can be used to fasten the rails and stiles together. Dowels can fasten the joints, or one of several new systems can be used.

For example, Kreg Pocket-Hole joinery is quick and easy, but will leave screw holes in the back of the door (www.kreg.com). The Beadlock joinery system from Rockler features a patented jig and specially designed “loose” tenons that are glued into the holes created (www.rocklerpro.com). The new Festool Domino Loose Tenon Joining system utilizes an elongated hole that mates perfectly with the Domino tenons sold with the tool (www.mcfeelys.com). If the face frame is wide enough biscuits may also be used, but they don’t provide quite as much support.

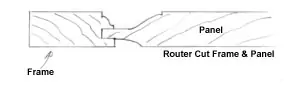

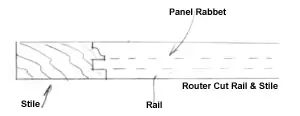

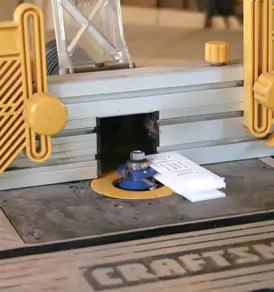

Today, most frame-and-panel doors are created using a rail-and-stile bit set in a router that is mounted in a router table.

The most common method, and especially useful when doing a lot of doors such as for kitchen cabinets, vanities and other cabinets, is a rail-and-stile bit set used with a router in a router table. These not only create the rail-and-stile joints that are then glued together, but also a profile on the inside front edge of the frame, as well as the rabbet for the panel. These come in sets of two, one for the “cope” and one for the inside profile and rabbet in the rails and stiles. Different profiles are available with the most common being Roman Ogee, Round Over, and Cove & Bead. Many companies also sell the bits in a set with a mating raised-panel profile for cutting the raised panels. The CMT Sommerfeld Cabinetmaking Set also includes a drawer-front cutter.

Woodline USA, (www.woodline.com) carries a full line of rail-and-stile and raised panel bits and bit sets, including a 3-piece Raised Panel Door Set and the Sam Maloof Signature Series 6-piece Cabinet Set. Woodline also sells setup blocks to match their bit sets. These HDPE blocks make it easy to mate cuts for rails and stiles. Merely slide the block next to the bit and raise or lower to determine the mating cuts.

You will need a sturdy router table and a fairly powerful router with variable speed and a 1/2-inch chuck, such as the new Craftsman Professional 1-1/2 HP model.

Making Doors with a Router

You will need a heavy-duty, variable speed router with a 1/2-inch shank chuck and a sturdy router table for using these large-diameter bits. The tools used for this article included a Craftsman Professional Router Table and the new Craftsman Professional Router. The 2.25-horsepower router with fixed base provides variable speeds from 12,000 to 25,000 rpm (no load). Electronic feedback control ensures the proper rpm for the bit size and material hardness throughout the cutting operation. The new router features direct-connect motor sleeve height adjustment. Micro-height adjustments can be made in 1/64-inch increments by simply turning the height-adjustment knob. To make rapid adjustments of 1/2-inch or more, a button can be depressed to bypass the direct connection. The router also has a quick-release latch to facilitate removal of the motor pack for bit and base changes. When attached to a router table, bit-height adjustments can be made from the top of the table where the work is performed.

First step is to make the cope cuts on the cross grain ends of the rails. Set the fence on the router table almost flush with the cutter bearing. Use wooden push blocks to push the ends through the cutter head. Then set up the profile and rabbit cutter head, and cut the inside of both rails and stiles. This usually takes two bits, but CMT makes a single bit that can be used to cut both profiles by simply changing the bit height.

Straight raised panels can be cut on a table saw by angling the blade.

With the rails and stiles cut, the next step is to cut the panel. Flat panels are easy. You can use 1/4-inch plywood or plane solid stock to 1/4-inch thickness for the panels. Raised panels can be cut in several ways. Square or rectangular panels can be raised by tilting a table saw blade, removing the splitter and guard, and running the edges of the panel across the blade. Vertical panel cutters that are used in a router table are also available for square panels.

Arched rails and matching panels are precut using a bandsaw with a template on the stock. The edges are then flush-trimmed using the template riding on the bearing of a flush-trim bit.

Arched and cathedral raised panels are mated with a top arched rail. Both must be cut on a router table, however the large bit must be run extremely slowly and the wood fed slowly into it. You can simply design the arch, cut the rail and door to match with a bandsaw, and then rout. These techniques are more difficult, so practice on scrap wood.

The cove or cross-grain cuts on the rails are first cut using a fence and push sticks. A miter gauge also helps steady the work.

The CMT Sommerfeld Cabinetmaking Set, combined with their arched rail templates, makes the chore easier and more precise. First, cut all pieces to size and shape. Note: The rails must be cut long enough for their profiles to fit into the stiles. Cut the arched rails using the selected template sold separately. This should be cut about 1/16-inch wider for trimming (see photos on pg. 80). Set up the cope cutter to make the cuts in each end of the rails. Set the fence even with the cutter bearing and use a wooden push stick to push the stock through for the cut. Place the template onto the arched rail stock and fasten with nails driven through the template holes and about 3/8-inch into the stock. Cut the arch using a bandsaw and cut to within about 1/8-inch of the template. Place the flush trimming bit in the router table and position so the template meets the bit bearing. Trim the rail, then remove the template, turn it around and use it on the raised panel stock to cut and trim it.

Shown is the installed profile bit. The woodline setup block makes it easy to set the bit height for mating the two.

Note: If making several doors, do all doors through each step. Set up the pattern cutter for the inside profiles and use the template against the bearing to cut the inside of the top arched rail. Reinstall the fence and cut the inside profiles on the straight bottom rail and the two stiles.

The inside edge profile and back panel cuts are made at the same time with the cutter.

To cut the raised panel, set the fence so it is even with the bearing on the panel cutter, and the cutter is of the correct height. Run the router at about 10,000 rpm and use wooden push blocks. Rout the straight cross-grain bottom edge first, and then cut with the grain on the left side. Using a half fence set-up, re-cut the left side and continue around the curved top of the panel freehand. Carefully and slowly feed the arched panel against the cutter, again with push blocks. Reinstall the full fence and complete the panel by cutting the right side.

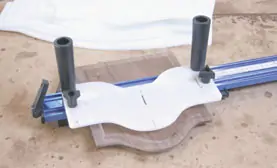

Woodline has created a unique new Raised Panel Door System that takes a lot

of the guesswork and hassle out of the chore. It comes with a set of templates and a jig to hold the template and work stock.

New System for Frame and Panels

Woodline USA has just introduced a new Raised Panel Door System, and Extreme How-To was the first to test it. In fact, we had the only prototype. The unique system utilizes templates and a holding jig that makes it much easier and safer to make the arched rail and panel cuts. In this case, the template is used to mark the shape of the arch and again the arch cut on a bandsaw to about 1/8 to 1/16 inch. The template is fastened to the holding jig and the stock clamped in place. The flush-trimming bit is set so the bearing rides on the template edge and the stock is trimmed flush. The holding jig slides on the router table and has a pair of handles that make it easy to guide the stock into the cutter. The flush-trimming bit is removed, the cope bit installed. The fence is reinstalled, and the cope cuts are made on both the upper and bottom rails. The profile cuts on the stiles and bottom rail are then cut with the profile bit. The fence is removed and the inside profile is cut on the rail freehand, again using the handles to feed the stock into the cutter.

The jig holds the selected template to match the stock profile and the inside profile cut on the arched rail. Simply guide the jig and stock against the cutter with the handles.

The template is reversed on the holding jig and the panel door arch cut to match the template. The flush-trimming bit is then used to trim the panel arch flush. The panel-raising bit is installed, and the jig is used to guide the arched panel portion through the cutter. The fence is then reinstalled, and the bottom cross-grain cut is made, followed by the two side cuts.

The holding jig is then used with the reverse side of the template to cut and shape the arched door top.

Sand the panel thoroughly, then glue. Note that the panel is not glued in place, only the corner joints of the rail and stiles are glued.