Relax in style with a classic bench swing

Porches have become increasingly popular, and an old-fashioned porch swing is reminiscent of the romance of yesteryear. You can build your own “classic” porch swing and match it to your décor. Porch swings are often exposed to some weather and they must be sturdy. The swing shown was constructed of red oak, cut and dried from the author’s farm. Sikkens Cetol SRD in Cedar Tone was used to provide weather protection and also added a “golden glow” to the swing. Although the swing shown looks fairly easy, it requires some special tools and skill to build. The swing support pieces are all cut from 3/4-inch solid red oak, while the back slats and seat slats are of 1/2-inch red oak. You can purchase wood in these thicknesses or if you have a planer, you can plane materials down to the correct thicknesses. The swing is constructed in four steps: the seat assembly, the back assembly, the arms assemblies and then installing the support chains.

Seat Assembly

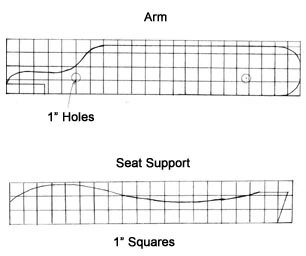

First step is to enlarge the squared drawings found throughout this article for the seat supports, back slats, top back support, arm supports and arms. Create patterns of cardboard from the enlarged drawings. Incidentally, you may get requests to make additional swings, so it’s a good idea to keep patterns of the various pieces. One-half inch wood or 1/4-inch hardboard can be used to create the patterns for future use.

Left: As the swing uses two different thicknesses of material, first step is to plane to the correct thickness, then rip the various pieces to the correct widths and joint all edges. Right: Enlarge the squared drawings to create patterns, then cut the pieces such as the seat supports on a bandsaw.

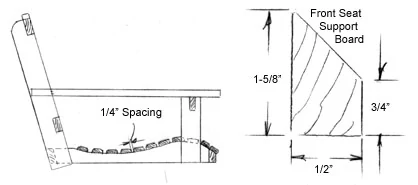

Rip the pieces to the correct widths, plane both edges, then cut to shape using a bandsaw. Sand all rounded edges using a spindle sander, drum sander or the rounded edge of a combination belt and disc sander. Rip the rear and front seat support boards. Note the front seat support board has an angled edge. Rip this on a table saw to create the proper angle. Rip the 1/2-inch seat slats to correct width and then run their edges over a router table and round-over bit to lightly round the sharp edges.

A drum or spindle sander is used to sand all curved surfaces.

Lay the seat supports on a smooth, flat surface in their correct locations. The entire assembly is fastened together with Kreg Stainless Steel Maxi Loc coarse washer-head, self-tapping screws in counterbored holes. Determine the location of the holes in the ends of the front and rear seat support boards. Counterbore the holes using a portable electric drill and counterbore bit, or a drill press and a 3/8-inch forstner bit, to create the hole for the screw head. Finish by boring through the boards and slightly into the seat supports with a 1/8-inch drill bit. All joints must be predrilled to prevent the oak from splitting.

Fasten the front and rear seat boards to the end and center seat supports through the pre-drilled and counterbored holes. Make sure the assembly is square. Counterbore and pre-drill the holes in the top of the slats and down into the seat boards. Anchor the slats in place with the screws, setting them slightly below the wood surface. When all slats are installed, lightly sand to remove any wood chips or roughness on the slats and the ends. At this point you may wish to finish the seat portion by applying the Sikkens with a soft-bristle brush, making sure to wipe away any runs.

The entire swing is assembled using Kreg Stainless Steel screws in counterbored and predrilled holes.

Back Assembly

While the seat assembly finish is drying, assemble the back. Cut the back slats from 1/2-inch oak and, using a bandsaw, cut their profiles. Sand the profiles using a belt sander, sanding drum or spindle sander.

Left: The seat slats have their top edges rounded using a round-over bit in a router table. Right: The simplest way to do most of the counterboring is with a forstner bit in a drill press.

The ends of the slats have tenons cut in them. This can be done using a table saw with a tenon cutter or dado head. You can also cut these quite simply with a radial arm saw and dado head, such as the Freud model. Simply position a 1/2-inch stop block to hold the slats against. Anchor the stop-block to the radial arm saw table with a clamp. Hold the slat in place and run the dado across each face on each end. Lightly sand the cut ends to remove any splinters. With 15 slats needed, it’s not a bad idea to do each step on each slat, and then move to the next step.

Left: Construct the seat assembly first and make sure it is square. Right: The back slats are held in place with mortise and tenon ujoints. Lay out the mortise joints.

The slat tenons in the porch swing fit into mortises cut in the upper and lower back supports. This takes a bit of work and some fairly precise cutting. A simpler method would be to run a dado on the top edge of the bottom back support and the bottom edge of the upper back support. Then cut the slats so they completely fill the dadoes without any spacing between. My original design was this, and then I decided the back needed a more open appearance so I went with the more difficult method.

Left: Rough cut the mortises with a forstner bit and a shop-made fence on a drill press. Right: True-up the mortise ends and edges with a sharp bevel chisel and mallet.

The mortises can be cut in a number of ways, but remember there are 30 mortises to cut. A mortising machine makes the chore simple. You can even hand-cut the mortises with sharp chisels and a mallet. I used a 1/4-inch forstner bit in a drill press to rough cut the mortises, stopping the bit to create a 1/2-inch deep mortise. I used a hand-made fence clamped to the drill press table to hold the boards in the correct position for cutting the mortises. Regardless of the method used, make sure to layout the mortises with a sharp pencil on both the upper and lower supports at the same time, so they match.

Left: Clean up the mortises and remove the waste material with an edge chisel the size of the mortise. Right: Cut the slats to size and then cut their curved shapes.

Set a combination square to mark the distance from the sides as well as the ends of the mortises. Once the mortises were rough cut on the drill press, they were trimmed square and smooth using a pair of chisels—a 1-1/4-inch wide chisel for the edges and a 1/4-inch wide chisel for the ends and to clean out the bottoms of the mortises. Counterbore holes for the screws in the ends of the support pieces.

With the slats and upper and lower back supports cut, the next step is to assemble them and this is best done with two people. The slats can be glued in the mortises, but it’s best to leave them unglued for better wood movement when the pieces shrink and swell from exposure. Dry-fit the slat tenons in both the upper and lower mortises to make sure everything fits. Then lay the upper and lower back supports on a smooth, flat surface and insert the slat tenons into the mortises. Use clamps to draw the assembly up fairly snug so no joint lines show. Cut the back uprights to size and shape. Then position the back assembly over them and mark for the notch locations. Cut the notches. Reposition the back assembly over the uprights and predrill through the counterbored holes and into the end pieces. Fasten in place with one screw at each joint and then check to make sure the assembly is square. When square, install the remaining screws in the joints. Turn the assembly over and cut and install the back braces. These are fastened to the upper and lower supports to prevent them from separating and allowing the slats to fall out. You may wish to stain or finish the back assembly at this point.

Left: Sand on a drum or spindle sander. Right: Cut the tenons on the slats using a table saw and/or tenon cutter, or a dado head on a radial arm saw (as shown here).

Once both assemblies have dried, counterbore a hole in the bottom end of each back end piece and fasten the back assembly to the seat assembly. Make sure the back is at the correct angle to the seat. Cut the front uprights to size. Counterbore and predrill the bottom of the front uprights, then anchor in place to the seat sides, making sure they are square with the bottom of the seat supports.

Arm Assembly

Next, cut the arms to the correct size and shape. Bore the holes through the arms for the support chains. Thoroughly sand all contours. Cut the front arm angle supports to size and shape and counterbore and predrill for all screw holes. Install the arm angle supports on the outside of the front uprights and flush with their top edges. Counterbore and predrill the screw holes at the back of the arms. Then install the arms down on the arm supports, anchoring with screws from the underside of the angled arm supports and into the underside of the arms. Anchor the back of the arms to the back uprights with counterbored, predrilled screws. Incidentally, you may wish to dry-fit these arm pieces, stain or finish and then install. Note: To clarify, the front uprights should be installed 2-1/2” back from the front edge of the front seat support. The arm is installed with its front edge 1-3/4” past the front edge of the front upright. The angle of the back uprights simply follows the angle of the rear seat support.

Assemble the back using clamps to hold it together until all pieces are screwed together, including the back braces.

Hang it Up

The swing shown is hung from a single chain joining two separate chain pieces on each end with a screw-together chain link. The first chain is anchored to the front of the seat with a bolt through the front upright and seat support. Washers and a locking nut complete the assembly. The second chain piece runs from the back upright and seat support and is attached to the front chain 12 inches up.

Left: Cut and assemble the arms. Note: The arms must have an angled notch cut in their back ends to meet the angle of the back. Right: It is easier to finish the individual assemblies rather than the entire swing.

It’s also important to make sure the porch swing is suspended by sturdy supports. If the porch ceiling is supported by 2-by-4’s you should add more strengthening with blocks on each side of the support beam. The swing can be hung from heavy-duty screw eyes, but an eyebolt is the safest and best choice.

Left: Rear braces keep the back from spreading apart. Right: The swing is suspended with a chain held in place with a bolt, washer, chain, washer threaded through the wood, then another washer and lock nut.

Now it’s time to sit back and enjoy your favorite summertime beverage as you gently swing your troubles away.

Materials List

• Seat Supports, 3/4 x 2-5/8 x 19-3/4”, 4

• Front Seat Support, 3/4 x 1/2 x 48”, 1

• Rear Seat Support, 3/4 x 2 x 48”, 1

• Seat Slats, 1/2 x 1-3/8 x 48”, 11

• Top back support, 3/4 x 3 x 49-1/2”, 1

• Bottom back support, 3/4 x 2 x 49-1/2”, 1

• Back uprights, 3/4 x 2-1/2 x 18-1/4”, 2

• Back slats, 1/2 x 2-1/2 x 10-3/4”, 15

• Back braces, 3/4 x 1 x 12-3/4”, 2

• Front arm supports, 3/4 x 2 x 2-1/2”, 2

• Arms, 3/4 x 3-1/2 x 22-3/8”, 2

• Front uprights, 3/4 x 2-1/2 x 8-7/8”, 2

• Heavy-duty, twisted-link chain, 17’

• Screw chain links, 2

• Bolts and lock nuts, 6 3/16 x 2 1/2”, 4

• Washers, 12

• Screws, 82