Roofing installation is a big job, and not just in the size of the project. As the number one weather barrier of the home, the roof is one area where you do not want any mistakes. A first-time roof installation is best left to an experienced professional. The pros are trained how to properly construct the roof deck, how to install underlayment, drip edges and flashings and how to correctly apply the shingles. Roofing is also hazardous work, leading most manufacturers to specify that their product only be installed by a trained professional.

However, do-it-yourselfers who aren’t afraid of heights or hard work have been known to tackle a re-roofing project first-hand. While asphalt shingles are designed for decades of low-maintenance performance, after about 20 years the roof should be inspected annually, and eventually it will need to be re-shingled. When that time comes, a DIY re-roofing project can save about 50 percent on the cost of the job.

Assessing the Roof

Asphalt shingles are the most widely used roofing material in residential construction, accounting for roughly 80 percent of the market. Today’s asphalt roofing greatly outperforms the shingles available 30 years ago. Season after season, asphalt roofing will protect you and your family, and provide a terrific value for your roofing investment. Asphalt costs significantly less than higher-priced rivals (including tile, wood, cedar, slate and metal) and requires very little maintenance over the years. And shingles come in a wide range of colors that allow you to choose a tone that complements the exterior colors of your house.

After a couple of decades you’ll need to inspect your roof for signs of deterioration. The most obvious perpetrator is a roof leak, indicated by water stains or wet areas in the attic. In some cases these can be patched, but in the case of a serious leak, it’s time to re-roof. Also, excessive mineral granules or bare spots on the shingles are evidence that the asphalt is deteriorating and should be replaced. Shingles also tend to crack or curl from sun exposure, and wind can blow them off the roof—a sure sign that a repair is in order.

In some cases you can shingle right over a pre-shingled roof (see Side Note at bottom). However, you have to consider weight, smoothness of the existing roof, local codes and the capability for fasteners to hold the shingles securely. Fasteners must be long enough to completely penetrate at least 3/4 inch into the solid roof deck when hammered flush with the shingle. So if the roof has already been re-shingled in the past, then there will likely be too many layers for the fasteners to hold properly. In many cases, two layers of shingles is the maximum.

If the roof is in bad shape or too many shingle layers are in place, then the roof requires a tear-off. A hammer and pry bar are used to loosen the nails, and the shingles are removed with a flat shovel. Tearing off roof shingles is hard work, but it does provide the opportunity to thoroughly repair the roof and update your material from standard three-tab shingles to attractive asphalt architectural shingles that can raise the overall value of the home. Architectural shingles last longer and look a little different. Instead of slots in the shingle, the architectural types get their texture from tabs that are laminated onto the shingle. This provides extra thickness and, in turn, more durability. For the most part, architectural shingles install similarly to the three-tab type, but always check your manufacturer’s instructions for any recommended variations in the installation method.

Getting Started

The first step in a roof project is to check the weather report. Ideally, you don’t want any showers heading your way for the next three days. However, as Mother Nature is known to be unpredictable, have a couple of tarps on hand in case of rain.

If you’re re-roofing, first nail down all loose shingles and replace any that are missing. Or, with a tear-off, make all the necessary repairs to the roof sheathing, underlayment, wood trim and flashing. The roof surface must be dry, cleaned and properly prepared before roofing. For more information on proper sheathing and flashing techniques, check out the variety of online roofing articles at www.extremehowto.com and www.apawood.org.

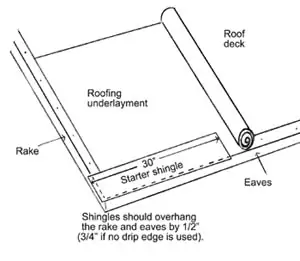

Appropriately enough, shingling a roof starts at the roof edge with what is called a “starter strip.” At the lower end of a standard shingle are three tabs separated by slots about 3/8-inch wide. The starter strip prevents rainwater from flowing through these slots and onto the roofing underlayment. To create the starter strip, first cut off the tabs of the first shingle and discard them. Cut from the back side of the shingle when possible to avoid dulling the knife blade. Then cut 6 inches off the first starter-course shingle and apply the rest of it on the lower corner of the roof, with the cut edge overlapping the eaves and gutter apron. The shingle should overlap rakes and eaves by 1/2 inch if using a drip edge. If not using a drip edge, make the overhang 3/4 inch. Continue applying full-length starter-course shingles along the eaves.

Shingle All the Way

With the starter strip complete, you’re ready for the first course. Apply a full shingle at the lower roof corner on top of the starter course. The tabs of the shingle should be flush with the edges of the starter course. This method seals the lower edge of the roof to help prevent the edge shingles from lifting in high winds.

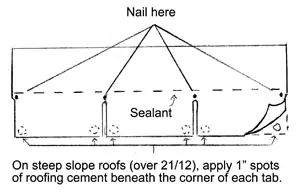

To fasten the shingles, apply four nails through the tabs just below the sealant line, 1 inch from each edge and just above each slot. In areas exposed to high winds, six nails can be used (two nails flanking the top of each slot). Use 11- or 12-guage corrosion-resistant roofing nails at least 1-inch long with at least 3/8-inch heads. Make sure the nails are driven straight, not overdriven or under-driven. Check your manufacturer’s instructions for specific nailing requirements.

In steep slope applications (over 21/12), asphalt roofing cement should be used in conjunction with nails. One inch of roofing cement should be applied beneath each corner of the tabs. However, working on a steep slope can be very dangerous and require special scaffolding; such projects are best left to the professionals.

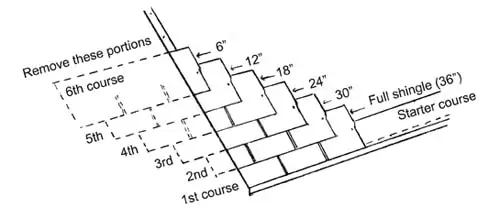

Once the first shingle is in place, snap a chalk line from the top of the shingle to the opposite edge of the roof. Then move to the first shingle of the second course. This helps align the shingles, and moving up rather than out means you don’t have to journey across the roof with each successive shingle. Cut 6 inches off the first second-course shingle. Align the bottom edge of the shingle with the top of the tabs of the first shingle. Nail it in place.

With those shingles in place, move to the third course. Cut 12 inches off the first third-course shingle. Align the bottom edge with the top of the slots in the second-course shingle, and nail it home. Continue progressing up the roof, nailing the first shingle of each course 6 inches narrower than the one beneath it (see diagram). After the sixth course, you will begin with another full shingle aligned with the edge of the roof.

After you’ve worked up to the roof ridge, return to the lower edge of the roof. Butt a full-length shingle next to the first-course shingle and nail in place. Continue back up the roof, nailing a full-length shingle against each of the starting shingles that are already in place. Follow this shingling procedure to complete the field of the roof. All the shingles are full-length except the ones at the edge of the roof.

At the edge of the roof, use a straight edge to cut the shingles to overlap the rake by no more than 3/4 inch. On hips and ridges, trim the shingles flush with the centerline.

Hips, Ridges and Valleys

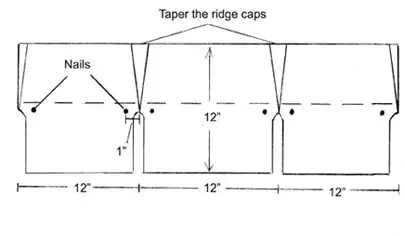

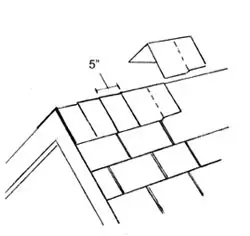

Hips and ridges must be covered by 12-inch ridge caps. Some companies offer special ridge cap shingles. Check to see if they’re available for the shingles you’re installing. If not, then make the caps from regular 36-inch shingles cut into thirds, separated at the tabs. Cut the sealant ends of the tabs so they taper to about 10 inches. To install, snap a chalk line on each side of the ridge or hip, 6 inches from the center line. Start with the first cap at the end of the ridge opposite from the prevailing wind direction. Bend the cap over the ridge along the center line. Fasten with two nails on each cap, just above the sealing tab and 1 inch from each edge. Overlap the caps by 1 inch, leaving a 5-inch tab exposed. Do not expose the fasteners.

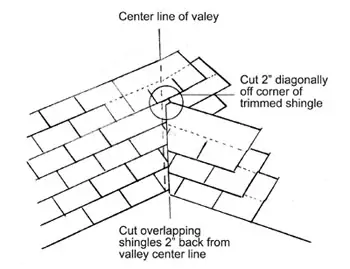

As for valleys, in some cases a non-corrosive prefabricated metal flashing is installed, and the shingles are cut back to allow drainage. This is called an open valley.

A closed cut valley is installed over a heavy-duty valley liner or metal roll flashing. Shingles are then overlapped. (Do not nail shingles within 6 inches of the centerline.) Then a straight line is cut through the top layer of shingles 2 inches away from the centerline of the valley. The 2-inch offset prevents the majority of the water runoff from flowing directly over the seam. When cutting, use flashing beneath the top layer to prevent cutting the layer below.

For more information on asphalt roofing, visit the Asphalt Roofing Manufacturers Association online at www.asphaltroofing.org or call (202) 207-0917.

Photos courtesy of Certainteed

Side Note #1

Shingling Over an Existing Roof

The process of re-shingling or re-roofing is only slightly different from installing a new roof. On a new roof the underlayment is smooth, lying flat on the roof sheathing. On an existing roof, the surface is not smooth because of the shingles, which are installed in stair-like layers. Since asphalt is a plastic material, the shingles will conform to the surface of whatever is beneath them. To compensate for the lack of flatness, simply fill in the first step of the shingles. Cut off the top of the shingles lengthwise to fit perfectly over the bottom row of tabs on the existing roof and nail them in place. Start with a shingle cut 6 inches short, so the ends won’t align with the ends of the existing shingles. Complete the bottom row in this manner using full-length “filler” shingles. Each new row of shingles fills in the gap for the row to follow. From here onward, shingle as you would a normal roof, covering the first course with full-width shingles.

Side Note #2

Ten Tips for Successful Roofing

1. Proper flashing around chimneys, vent pipes, dormers and other obstructions is critically important to avoid leaks. If you’re unsure how to do this, then leave it to a professional.

2. In roofing, properly installed underlayment is also critical for a good roof. It comes in 15- or 30-pound roofing felt that’s soaked in asphalt. Use felt specified by the shingle manufacturer. It is installed beginning at the bottom of the roof. Each strip overlays the strip below by a few inches, so flowing water is directed over the seam and not into it.

3. When cutting shingles, it’s easiest to use a roofing knife with a hooked blade.

4. Don’t attempt to shingle in extremely cold or hot weather. In cold weather, shingles can become brittle and break. In hot weather you can scar the shingles with your feet.

5. The sealing of the shingles may be delayed by cooler weather or by the presence of airborne dust. If the shingles don’t seal, it may be necessary to hand seal.

6. Installation of laminated architectural shingles may vary from the 6-inch layout discrepancy shown in this article. They may need to be stepped off 7 or 8 inches. Check the manufacturer’s instructions for recommended installation methods.

7. Save the trimmed pieces of stepped-off shingles to fill in at rakes and valleys.

8. Use all shingles from one bundle before moving to the next bundle. This will help the colors blend on a finished roof.

9. If possible, have the roofing supplier place the shingle bundles on the roof so you don’t have to carry all the shingles up a ladder.

10. Always check with local building codes that may specify the rating of shingles and other construction requirements that may apply to your area.

Side Note #3

Shingle Safely

The right gear is essential for safe roofing. The roof surface is sloped and it can be slick. Walk on the roof as little as possible and wear soft, rubber-soled shoes with ankle supports to resist slips. A wet roof can be treacherous, so stay off it. And steep slopes are best left to the pros. Never work on the roof during the threat of lightning. Stay away from power lines and keep the roof clean of debris or other obstacles.

It is recommended to use a safety harness with a fall-arrest rope. Special roof scaffolds can provide a flat surface to support you and your materials. Use a metal ladder bracket to hook your ladder to the roof. Make sure your ladder is strong, sturdy and free from cracks or other weaknesses. Keep the base on firm, level ground. Keep your hips between the ladder rails, and never reach out to work; move the ladder instead. Only one person should ever be on a ladder at once. Never stand on the top two rungs of the ladder. For roof work, at least two rungs should extend above the eaves. Rather than carrying tools and materials up a ladder, pull them up in a bucket.