Editor’s Note: This article is intended primarily for EHT readers employed in the field of professional remodeling/renovation.

So you’ve taken the RRP training, and you’ve become a Certified Renovator. Now, you give out the Renovate Right pamphlet to clients, occupants, and/or parents before every remodel job on an old building. You put up containment, train your employees, use lead-safe work practices, and clean the job site within an inch of its life. You do cleaning verifications, or better yet, clearance exams.

So you’re safe, right? Safe from EPA audits, safe from litigation, safe from outrageous fines and penalties?

Hmmm. Not quite.

As you may have heard before, “the job isn’t over until the paperwork is done.”

One section of your Renovate, Repair, and Paint (RRP) training dealt with record keeping. But many Certified Renovators admit that they’re more confused about what records they have to keep after the training than they were going in. And since your trainer may not have had the time to get into the nitty-gritty details of documentation, you may not have gotten a clear idea what you have to document. (I heard one RRP instructor say, “go home, read the law, and spend about 40 hours figuring out how to create a record keeping system.” Clearly, not very helpful.)

But make no mistake about it. Record keeping is a very important part of the RRP process. The EPA probably isn’t going to swoop down upon your job site at the exact time that you happen to be disturbing lead-based paint. No, it’s much more likely that they’ll contact you and ask you for your records pertaining to that job you did on Oak Street back in November of last year. “Oh, and while you’re at it, could you please send us all your records from all the other jobs that you did on pre-1978 houses, dwellings, and child-occupied facilities.”

And in a court of law, the lawyer certainly isn’t going to take your word for it that you put up containment, or used a HEPA vacuum, or cleaned the floor well enough that you could eat off it. You’ll need some kind of proof that you followed lead-safe work practices. (However, if the lawyers discover that you used lead-safe practices and have adequate records, they’re more likely to look elsewhere for the source of their client’s lead poisoning.)

We’ll try to clarify your responsibilities and give you guidelines for the records that you need to keep to comply with the RRP Rule.

Record Keeping 101

If you already have a “job book” for each project, or have some other record keeping system that helps you document each project, then you can probably skip to the next section. But if keeping detailed records isn’t your strong suit, here are some tips.

1. Set up some kind of system. You need to create an organization scheme. It could be 3-ring binders, or different colored file folders, or electronic files—some system that forces you to keep your records organized. (And while a shoebox might work well for filing receipts from the hardware store, you’ll need to be a little more systematic when it comes to RRP records.)

2. Decide when you’re going to document your work. It could be at the start of each day while you’re drinking your coffee. Or, you could record everything each Thursday evening. But decide what’s most convenient for you, at a time when something else isn’t going to get in the way. Then commit do keeping your paperwork up-to-date. It’s a lot easier to document your work while it’s fresh in your mind than it is to try to remember what happened on a job you did 3 weeks ago.

3. Most importantly, stay with it. Record keeping is a skill that gets easier over time. And the more convenient your system is to use, the easier it will be to stick with it. If you need to, create a checklist of the records you need to keep. Then refer to the checklist on a regular basis to make sure you’ve covered all the bases.

What You Need to Document

First, a word about OSHA. OSHA has had regulations in place for 20 years regarding work that disturbs lead-based paint. These regulations include the process for determining how much lead your employees will be exposed to during the course of their work, and procedures for protecting the workers. There are records that you are required to keep, such as documenting your respirator program and your medical program.

The RRP Rule does not have these requirements. But that doesn’t excuse you from adhering to OSHA’s regulations and record keeping requirements. In fact, as a result of the RRP program, OSHA is more apt to catch you for violating lead work procedures.

The RRP Rule only requires that you keep records on dwellings and child-occupied facilities that were built before 1978. If you test for lead-based paint and discover that none is present (or, that the lead-based paint won’t be disturbed by your remodeling or painting project) an abbreviated set of records are required.

The EPA requires that you keep the following seven different pieces of information on each project. This information follows the general progression of a “lead job”:

● Assign a Certified Renovator

● Educate the client (or occupant, or parent)

● Test for lead-based paint

● Train your workers

● Work safely

● Clean up thoroughly

● Report to the client

Assign a Certified Renovator

A Certified Renovator must be assigned to each project that involves a pre-1978 dwelling or child-occupied facility. You have to keep a copy of the Certified Renovator’s certificate (as well as the Certified Firm’s certificate) on the job site for the duration of the activities that disturb lead-based paint.

You should also keep a copy of the Certified Renovator’s certificate in your records. There’s always a chance that the Certified Renovator isn’t going to work for you two years from now when the EPA comes calling. And while the EPA has a database of all Certified Renovators, it will be a lot more convenient if you have their certification number on file.

Educate the Client

The EPA wants to make sure that the public is informed about the dangers of lead-based paint that could arise from the renovation activity. They’re paying special attention right now to whether you’re “educating” your clients by giving them the pamphlet, The Lead-Safe Certified Guide to Renovate Right. When you give the client, or occupant, or parent (if you’re working in a Child-Occupied Facility), the pamphlet, make sure you get some form of proof that you gave them the pamphlet.

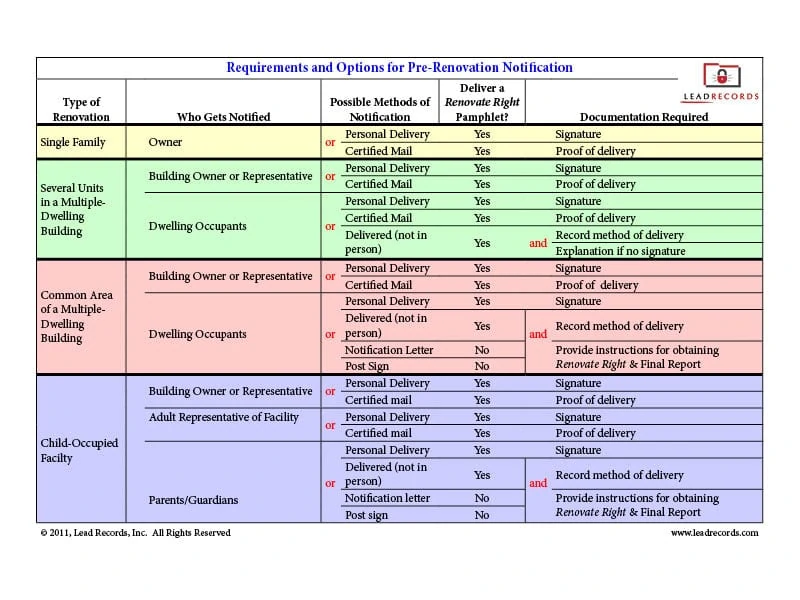

Depending on the type of building you’re working on, the EPA has different requirements for who needs to be notified, and how you can notify them. Refer to the chart, Requirements and Options for Pre-Renovation Notification, for a summary of the EPA’s requirements.

There are only two ways to notify an owner—whether that’s the owner of the house where you’re working, or the owner of the building. You can hand deliver the pamphlet (and therefore get a “live” signature) or mail the pamphlet to them. If you hand deliver the pamphlet, you can give it to them anytime (up to 60 days) before the work starts.

If you mail the pamphlet, it has to be mailed at least 7 days (but no more than 60 days) in advance. You have to send the pamphlet certified mail, with a return receipt requested. Either way, the owner has to get the pamphlet prior to the start of your work.

If you’re working inside someone’s dwelling, but they’re not the client (for instance, if the building landlord has commissioned the work) you still must deliver a copy of the Renovate Right pamphlet to each occupant. But if you’re not able to get a signature from each occupant you have to document how you delivered the pamphlet and why the signature wasn’t obtained.

If you’re doing work in a “common area” of a building (for example, if you’re working in the laundry room of an apartment complex), you have to notify the building occupants of the upcoming renovation activity. You don’t have to give each occupant a pamphlet, but you need to make them aware of the scope of the renovation activities and you have to make free copies of the pamphlet available to them upon request. You can do this by hand-delivering notifications, by mailing them, or by posting signs in places where the occupants will be sure to see them.

If the scope of your project (i.e., the activities that disturb lead-based paint) changes, you need to re-notify every one of the changes. So if the start date, or the end date, or the scope of the project changes, remember to send a notice of the change, or change the information on the posted signs.

If you’re working in a Child-Occupied Facility, the notification procedures mimic those of work in a common area. You have to deliver pamphlets to the building owner and an adult representative of the facility. Then you have to notify the parents and guardians of all the children who are affected by the renovation.

In each case there are nuances regarding how the notification takes place. So document everything—how you delivered the pamphlets, when you delivered the pamphlets, who delivered them, why you didn’t receive signatures, etc. The Certified Renovator is responsible for this notification process, so he or she should sign any documentation that is generated.

Test for Lead-Based Paint

You need to document the lead testing product that you use. Different manufacturers provide different information (and call it different things). The Test Kit Documentation Form that you received in your RRP training class may or may not reflect the information of the test kit you use.

As you test each component that you will disturb, you’ll need to document the results. Identify the test kit from which the test swab or bottle came and the results of the test. Of course, you may choose to presume that lead is present on one or more components, and proceed accordingly. You’ll need to document that as well.

In some cases (like HUD projects) you’ll need to have a certified agency test for lead. In that case, you’ll need to record the information about the agency, including their certification number. They’ll give you a report of their results, and you need to store the report with your files.

If you test, and discover that no lead is present on any of the components you’re going to disturb, you don’t have to keep any other records. Bundle up all the documentation that you’ve created to this point, and store it away.

Train Your Workers

Your workers are key to your lead-safe work. The RRP Rule doesn’t require that they take the RRP training class (unless you’re working on a HUD job, in which case they may need to be trained). But the Rule requires that they receive training from a Certified Renovator. The Certified Renovator has to record all of the skills each worker is trained to perform.

Work Safely

From setting up containment to cleaning up the job site after the lead-disturbing activities have been completed, you have to ensure that proper work procedures are followed. When you document your project, note the work practices that you performed, and write a brief description of what you did to ensure clean, safe practices.

The Certified Renovator is responsible for this documentation, so s/he needs to sign the form when it’s complete. Some Certified Renovators go the extra step to have the client sign the form as well. This provides proof that the client concurs that lead-safe work practices were used.

Cleaning Verification

The Certified Renovator is required to conduct a Cleaning Verification (on interior jobs) to ensure that no debris or lead dust has been left behind. You perform the test using:

● one wet cloth per window sill

● one wet cloth per 40 sq. ft. of horizontal surface (countertops, book cases, etc.)

● one wet cloth per 40 sq. ft. of floor

Document each area that you test. If you fail the cleaning verification in one area, but not others, you will need to re-clean that area, re-test that area, and document that you passed the verification the second time. The Certified Renovator should sign the form, and you may choose to have the client sign the form as well.

Under certain circumstances (for example, on HUD jobs) you’ll need to have a certified agency perform a clearance exam. Record the information about the agency, including the firm’s certificate number, and keep a record of the report that they provide.

Report to the Client

The EPA has added reporting requirements to the RRP Rule. You are now required to give certain documentation to the client. This “final report” has to be delivered to the client at the time that you present the final invoice, or within 30 days of the completion of the project (whichever comes first).

If you’ve been keeping up with your record keeping, it won’t be hard to compile this final report. Just make copies of the documents you’ve already completed. The report should include, at a minimum:

● Results of the test for lead-based paint

● Documentation of the training of non-certified workers

● Documentation of the lead-safe work practices you used

● Results of the cleaning verification or clearance exam

If your project was in the common area of a multi-family dwelling, or in a Child-Occupied Facility, you must also make the final report available, upon request, to any occupant or parent/guardian.

Final Thoughts

Your digital camera is going to become your best friend. Take photos of anything that documents your compliance with the RRP rule. Photograph your barriers and your containment area. Photograph your work practices, and of your workers in personal protective equipment. It’s impractical to keep you lead test kits, or the cleaning wipes you used in the cleaning verification. Take photos of those items and label them. (A small dry erase board is very effective in captioning photos. Write the specifics of the photo on the dry erase board and place it in the shot.)

If you tackle an emergency repair project, you are excluded from most of the RRP processes. You must clean up the site and perform a cleaning verification. And you must keep records—information about the project location, the nature of the emergency, and the RRP processes that you didn’t perform.

You are required to maintain your records for three years, and you have to be able to produce the records upon request. So along with the record keeping system you create, set up a storage system as well. Label projects so that you can find them easily. It will pay to put a little thought into the system now, so that you’ll be able to rotate out the “expired” projects 3 years from now.

In the final analysis, the system that you use doesn’t matter as much as using a system. You can create a system of your own, or you can avoid the time and the headache by using a system that someone else has created. What’s most important is that you use some system, or you’ll get buried under the additional paperwork that the new law has created.

The EPA has said, in no uncertain terms, that your records (or lack thereof) are the “low-hanging fruit.” In a time of governmental budget cuts travel will be curtailed, your records will be the primary way that the EPA determines your compliance with the RRP Rule. Make sure you’re ready when they ask for your records.

Side Note

About 20% of the states have taken over responsibility for the RRP program in their states. Some of those states have duplicated the record keeping requirements of the federal program, but others have added a few additional documents. (For example, the state of Mississippi requires that you notify the Department of Environmental Quality at least 6 days before the start of your project.)

Check with your state to find out if there are any additional or different records that you need to keep. Or refer to the list of state differences at www.leadrecords.com/support

Resource Links

Information about the Renovate, Repair, and Paint rule

Complete solution for RRP record keeping

Map of EPA audit activities

http://www.shawnmccadden.com/epa-rrp-info/

Blog of up-to-date RRP information

About Jeff Vasek

Jeff Vasek is president of Lead Records, Inc., (www.leadrecords.com) a San Jose, CA-based company that was established to provide record keeping solutions to all professionals affected by the EPA’s Renovate, Repair, and Paint Rule. Jeff holds a Doctorate in Education from Virginia Polytechnic Institute and State University. Jeff is a certified RRP trainer, as well as a veteran of the construction industry and a long-time educator.