Trimming out a room is a hot project for DIY homeowners who want to dramatically accent an otherwise lackluster ceiling, wall or window.

In addition to traditional baseboards, chair rails, crown molding and casing, homeowners can also consider options such as fireplace mantels, cornices, medallions and more.

Choice of Materials

MDF (medium-density fiberboard) is often the trim material of choice because it’s less expensive than solid wood. Trim pieces made from finger-jointed wood are widely used in remodeling applications because they don’t have knots and imperfections like solid pieces can have. Most home centers sell both MDF and finger-jointed trim pieces in factory-primed standard lengths. An experienced carpenter can also fashion unique moldings made from solid woods, such as mahogany, maple and poplar. Solid wood can be stained instead of painted to reveal the natural grain.

Urethane, composites and other synthetic materials are popular choices for paint-grade trim. Although the products cost more than wood trim, they don’t have the same maintenance problems and are suited for outdoor use. Synthetics and composites resist insects, cracking, peeling, chipping, swelling, splitting and rotting, making them ideal for exterior use—as well as areas exposed to moisture, such as base molding in a bathroom or crown above a shower.

Most paint-grade trim products are sold pre-primed. If your selection is not pre-primed, you might consider both priming and painting all the trim pieces before you install them. This will reduce the time you spend working on your knees (for baseboards) or a ladder (for crown molding) and limit your post-installation painting to touchup work.

Learning How to Cope

When installing baseboards, crown molding and chair rails, it’s tempting to cut 45-degree miters at the corners and hope for a sure fit. The problem is that most walls aren’t 90 degrees. Joining two 45-cut molding pieces may give you a square joint, but a square joint may not work for your crazy corner. This problem might be due to a framing error or a buildup of drywall compound in the corner. But even a perfect miter joint can develop gaps when the wood dries and contracts in winter.

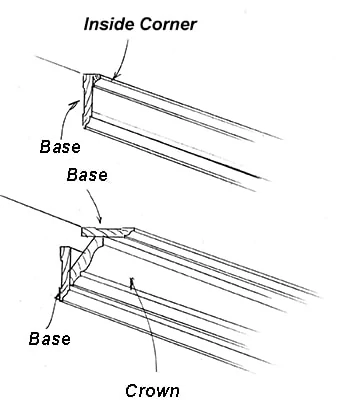

Unlike miter joints, cope joints have one trim piece butted against the adjacent wall at the corner. The joining trim piece is carefully cut to nest against the profile of the first. These joints eliminate the problem of out-of-square corners when installing trim, and they’re less likely to reveal a gap when the wood shrinks.

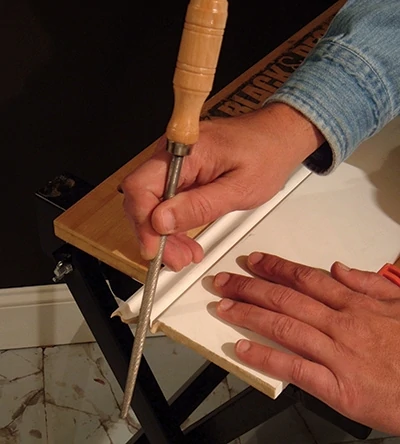

To make a cope joint, butt the first piece of molding into the corner and fasten in place. The second piece of molding should be cut a few inches longer than its final length. On the intersecting end of the second piece, cut a 45-degree inside miter. Run a carpenter’s pencil along the edge of the mitered profile, marking the shapes and curves for better visibility.

The traditional way to make the joint is with a coping saw. The thin, flexible blade of a coping saw is designed especially for cutting out intricate patterns. Clamp the second piece of molding securely to a work surface and use the coping saw to cut along the pencil line that marks the decorative pattern. It may help to angle the blade to back-cut the molding. Keep the blade about 1/16 inch to the waste side of the cutline.

When most of the wood is removed, use a file to finish up the cut and clean the profile, revealing a shaped edge that will be the only point of contact between the intersecting molding pieces. Remove all the wood in front of the profile to create a socket that fits over the face of the first piece. A “rat tail” file, which has a round, slender shape works well for fine-tuning small curves and edges. A flat file works well on square edges.

Test-fit the molding against the first piece. Check for any gaps and sand or file away any high spots for a good fit. Nail the molding in place and finish by caulking the seam. Proceed around the room to complete the installation.

Installation Sequence

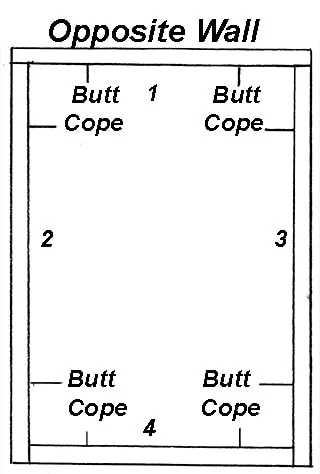

When coping base or crown molding, follow the installation sequence shown in the diagram for the best appearance. Begin on the wall that is opposite the door and install a piece that is square at both ends, flush between the two adjacent walls. This way, anyone walking into the room sees the best side of the joints. On the two adjacent or “side” walls, cope the joints where they meet the installed molding, but cut the opposite ends square and butt them against the “door wall.” The molding on this fourth wall should be coped in both corners, but the joints on the “door wall” are the least noticeable in the room in case of any minor imperfections. All moldings should be fastened securely into solid framing with two nails driven at offset angles per stud location.

Quick Tips for Molding & Trim

Make sure that each length of molding you purchase has the exact same decorative profile width and thickness. This is important because building supply stores purchase their own trim from several manufactures, each using their different fabrication standards/tolerances, and dissimilar pieces won’t fit together correctly.

Always check the square of your saw before you begin. For every degree your saw is out of alignment, you will get twice that error for each joint you cut.

When cutting molding or trim to the wall’s length, it is best to make the first cut at least 1/2 inch into the waste side of the crown or trim, and then make small cuts until you reach your length mark.

For added strength, use adhesive in all joints.

Caulk all joints and the top and bottom of your crown and trim. Use a shrink-free spackling for nail holes. (Caulking nail holes will leave visible dimples.)

Complex Moldings

Crown molding, baseboards, chair rails and casing are available in simple geometric profiles as well as elegant, intricate profiles that mimic complex classical designs assembled from multiple strips of different shapes. DIY’ers can purchase these moldings preformed at the factory or they custom-build their own from individual trim strips sold at home centers.

Dentil molding, for example, is a series of repeating rectangular blocks that adds depth and character to millwork such as fascia trim and crown profiles. This style of moulding has been popular for centuries, but traditional installation was a time-consuming and labor-intensive process that required combining all the individual pieces.

Today, wood moldings are available with the dentil molding preattached to the profile by the manufacturer. For paint-grade trim, synthetic moldings offer similar design advantages. You can purchase single-piece poly-urethane foam or vinyl molding, which weigh less and resist shrinkage, peeling and other problems associated with built-up wood molding. Plus, with paint-grade projects, minor errors in the installation can be repaired with caulk and painted over.

Some larger crown moldings will have a gap at the rear that makes it difficult for nails to penetrate solidly into the house framing. To create a solid nailing surface on which to hang the molding, install wood blocks along the perimeter of the ceiling. Measure the angle of the molding profile using a combination square, and then cut triangular blocks from scrap wood to fit behind the molding. Nail the blocks every 16 inches into the wall studs. Then, nail the molding into the blocks.

Don’t be afraid to get creative and develop your own moldings from any of the wide range of shapes and profiles on the market today. Practice the assembly on a workbench and be sure to keep your reveals consistent.

(The “reveal” is the exposure of one trim piece beneath another.) Make sure your built-up molding is securely attached with nails and glue, and the sky will be the limit on the designs you can come up with.

Think Beyond the Walls

Fireplace mantels, built-in bookshelves, bar areas and more make great candidates for decorative trim enhancements. Think outside the box when designing and selecting your trim packages, and don’t feel limited by the traditional use of the materials. Instead of crowning a wall, use molding to create skirting for a mantel shelf. Use a piece of baseboard turned upside-down to line the upper portion of a book case.

Side Note 1

Handy Tools

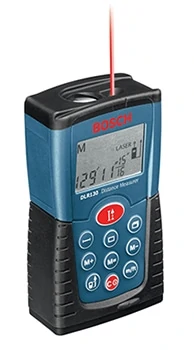

Accurate wall-to-wall measurements are critical for installing crown and base molding. Although a tape measure will work, a laser range finder will make the task easier. Just aim the device from one corner to the other. With the push of a button you have the exact measurement recorded in digital readout, and you’re ready for a trip to the saw to cut the molding to match.

If installing crown molding by yourself, check the local hardware store for crown molding hangers. To use them, tack a couple of nails about 6 feet apart just below the ceiling. Hook the Crown Hangers on the nails—they’re sold two per set. Then, hang the stick of molding on the two brackets. You can then adjust each of the hangers by sliding the brackets upward and finger-tightening with a lock nut, which positions the molding against the ceiling, ready for fastening.

Side Note 2

Ceiling Medallions

A ceiling medallion is an easy trim upgrade that adds elegance to a hanging light fixture. Some ceiling medallions come in two halves for simple application over an existing fixture. Others are single-piece products that require removal of the fixture. Some medallions are made of thin plastic and install with two-sided tape, but we prefer the solid urethane versions that can be securely glued to the ceiling. To install, all you need is a power drill/driver, a handful of trim-head drywall screws, wood filler and some construction adhesive.

To begin, test-fit the medallion and make note if it needs to be centered, in case the base of your light is slightly smaller than the medallion’s inside diameter. When you’re satisfied with its position, mark the ceiling around its perimeter for easy replacement after you add the adhesive. Liberally apply beads of adhesive to the medallion’s back (use polyurethane glue for urethane medallions). Replace the two halves around the light base and interlock the joint.

Countersink a couple of trim-head drywall screws through the medallion and into the ceiling joists to hold the trim piece while the glue sets. Conceal the small screw heads with plastic wood filler. Caulk the seams and paint if desired.