The Battlefield, Missouri, fire station was severely damaged. Under-reinforced masonry walls had a lumber nailer bolted to the top. The nailer supported open-web wood trusses spanning 50 feet. Trusses were toenailed to the nailer. As a unit, the roof lifted off of the building and shifted laterally. Many of the masonry walls collapsed, covering emergency equipment and personnel. One of the fire station workers reported that the building was only 10 to 15 years old.

Background

Sunday May 4, 2003, produced one of the most destructive weather systems in memory. This weather system produced strong tornadoes in eight states: Arkansas, Kansas, Mississippi, Missouri, Nebraska, Oklahoma, South Dakota, and Tennessee.

Three days after the storm, Bryan Readling and Vince Ellebracht of APA – The Engineered Wood Association’s Field Services Division made observations to a variety of structures in an area of Southwest Missouri damaged by a tornado traveling from Pierce City to Battlefield, Missouri. The National Weather Service classified the tornado along its path through PierceCity as F-3 on the Fujita scale. Observations in Battlefield were made on recently constructed homes and nonresidential structures. The homes were generally from 2 to 15 years old some were under construction.

Severely damaged homes in one subdivision in Battlefield, MO, were commonly missing either all or a large portion of the roof framing. Most of the roofs were stick-built with no light gauge metal connectors tying the roof framing to the top of the walls. Most of the homes in this subdivision were between 2 and 10 years old. This home was under construction but completely dried-in at the time of the tornado.

Common in this subdivision were large roof sections that had blown off of homes. Most of these were observed to contain only a few toenails into the support walls.

This detail of “house A” shows that the bottom plate of the garage sidewall is missing. Anchor bolts were typically located 8 feet on center at this location. The 16″ return walls were typically attached to the foundation with either one or two anchor bolts. Anchor bolts contained minimally sized round washers.

The return wall of this garage was attached with only one anchor bolt. Connection of the sidewalls and return walls to the foundation was inadequate. Better anchorage of the bottom plate to the foundation and better attachment of the wall sheathing to the bottom plate was needed.

Observations

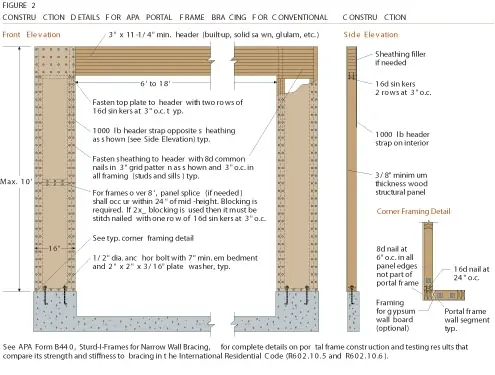

Light-gauge metal connection hardware at the rafter to wall intersection was observed to be missing on the severely damaged homes in one subdivision. Numerous roof rafters and sections of roof were observed as debris scattered within the damage site. Toenails, observed as the only attachment between roof framing and the tops of walls, offered little resistance to uplift forces from negative pressures on roof surfaces. Additional uplift loads were imposed on these connections when breaches in the building envelope occurred.

Garage doors tended to be constructed of lightweight metal and were no match for the pressures and flying debris accompanying the tornado. Breached garage door openings allowed wind pressures to act on the internal surface of structures, instantly combining with external pressures. This sudden combination of pressures resulted in rapid failures of the garage walls and roof. Failures resulting from breaches in the garage often appeared to include the walls and roof enclosing adjacent living spaces. In addition to the vulnerability of garages to breaching, the garage is generally weaker due to fewer structural redundancies that normally accompany conventional wood-frame construction. Narrow return walls (parallel to, and on either side of the garage door opening) were often incapable of resisting the lateral forces exerted during the high wind event. Numerous homes were observed where such narrow return walls had failed. Garage-wall-to-foundation connections (anchor bolts to bottom plates, bottom plates to studs) were often inadequate. In several cases the bottom plates of garage walls were found still attached to the concrete foundation and the studs were missing. Only the nails through the bottom plate and into the bottom of the studs remained. In this scenario, properly lapped and fastened structural panel wall sheathing can be an economical option for transferring forces around the stud-to-plate joint and then into the foundation. In other heavily damaged garages, the bottom plate was no longer attached to the foundation. In these cases, anchor bolts either split or pulled through the bottom plate. In general, minimally sized round washers were used.

The type of wall sheathing largely influenced the ability of walls to sustain impact from windborne debris. Most of the homes in one hard hit subdivision contained non-structural sheathing such as foam or fiberboard and vinyl siding. The few homes observed with plywood or OSB structural wall sheathing sustained far fewer breaches.

Wind-resistant designs should be considered for buildings constructed in tornado prone areas. Too often the accepted convention is that tornado winds are too strong for conventional construction. This is far from reality. About 90 percent of the roughly 1000 tornadoes reported each year are classified as F-0 through F-2 on the Fujita Scale. The wind forces associated with these less powerful tornadoes are similar to those designed for along much of the U.S. hurricane coastline. By APA’s observations in Battlefield, Missouri, severe structural damage to homes could usually be linked to some sort of structural inadequacy.

There is cause to construct homes for high-wind resistance. It may be reasoned that a home constructed in compliance with hurricane coastline wind loads could withstand full exposure to tornados classified up to F-2. Since tornado forces decrease dramatically within a short distance of the funnel, a well constructed home would also be less vulnerable to winds on the outer regions of an F-3, F-4 or F-5 tornado.

Minimum wind loads prescribed in the model building codes should be recognized for what they are: minimums. In cases where enhanced safety and security are desired, such improvements can be made with relatively small additional costs and with some additional attention to details on the part of the designer and builder. The value of such structural enhancements could be realized in lower insurance cost and improved occupant safety.

A detached garage was observed to be racked because of inadequate bracing of the front return walls.

This plywood sheathed house fared much better than the home in the background with mostly non-structural wall sheathing.

Construction Recommendations

Several steps can dramatically and economically improve building performance in high wind events:

• Fully sheath houses. A house fully sheathed and properly fastened with wood structural panels improves continuity and also helps resist flying debris.

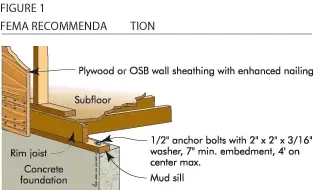

• Fasten structural panel sheathing in accordance with local building code and manufacturer’s recommendations. Close adherence to maximum 6″ o.c. nail spacing at supported panel edges helps walls behave as a unit. (See figure 1.)

• Use proper sill anchorage. Check local building code for correct bolt diameter and spacing/placement. Large washers are suggested between the sill plate and the nut (2″ x 2″ x 3/16″ washers are required in high seismic regions). FEMA recommends greater use of anchor bolts in addition to properly fastened structural panel wall sheathing. (See figure 1.)

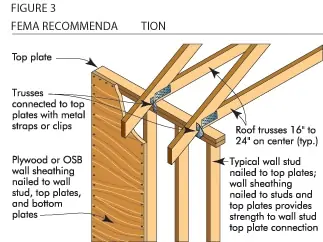

• Use portal framing when narrow return walls are desired at garages. Such framing details improve the bracing performance of narrow walls. (See figure 2.)

• Use metal connectors to tie roof framing to the top of walls. Uplift performance of straps or clips is better and more reliable than toenails. (See figure 3.)

Editor’s Note: This article was provided by APA – The Engineered Wood Association (formerly American Plywood Association), a nonprofit trade association whose domestic and international members produce a variety of engineered wood products. APA’s primary functions are quality inspection and testing, applied research and product promotion. Visit www.apawood.org.