Hammers are available in a wide range of types and sizes. It’s important to choose the correct hammer and size for the chore.

A hammer, in the form of a rock, was probably mankind’s first “tool.” Today hammers are still just as important. Hammers are available in a wide range of types and sizes, suited to specific chores. Hammers are also some of the most misused and abused tools. There is no such thing as a universal hammer, although we often treat hammers as such. It’s extremely important not only for safety, but for the life of the hammer, ease of use and success in the chore to choose the proper hammer for each task.

Many also feature longer, hatchet-style handles.

Claw Hammers

Claw hammers should be used only with non-hardened nails. These hammers are available in two styles: curved claw with 16- or 20-ounce weights used for general carpentry, and lighter 10- and 12-ounce weights used for finish carpentry or cabinetry. Straight-claw hammers are sometimes called ripping or framing hammers, and the straight claw provides more leverage for pulling larger nails when doing framing or remodeling work. These commonly come in sizes 20, 24, 28 or 32 ounces.

Claw hammers are available with a variety of handle materials, including hickory, steel and fiberglass. Most claw hammers feature a straight handle, but the California Framer hammers from Vaughan and the Plumb framing models, feature a hatchet-style handle. The Vaughan BlueMax model also has an innovative magnetic nail-holding slot for storing 16d and 20d nails. These are great for starting nails in places you can’t reach with both hands.

In addition, some hammers also feature unusual head materials and designs. For instance the Vaughan Ti-Tech Titanium hammer combines the speed driving power of titanium with the versatility of interchangeable steel caps. The lightweight titanium body swings faster for greater power at the point of impact with less stress and arm fatigue. The steel caps can be changed from a milled face for rough framing to a smooth face for finish work.

The shock-absorbing design of the new line of forged solid steel hammers from Plumb utilizes an exclusive patent-pending Vibration Reduction technology for a hammer that can be used all day, with less fatigue and a lower chance of joint discomfort. Dual-material, contoured grips add exceptional comfort and control.

Stanley has also introduced the new AntiVibe One Piece Forged Steel Hammer in either a nailing or framing hammer. The patented tuning fork design within the handle dampens the vibration created by continual hammering and decreases its transmission into the user’s arm and elbow. Both new hammers feature a specially textured, molded rubber grip for improved performance.

Ball Pein Hammers

These metalworking hammers are designed for riveting, center punching and bending or shaping soft metals. They are available in sizes from 2 to 48 ounces. It’s important to have a variety of sizes for different chores. One end of the head is round for riveting. The opposite end of the head is flat, but has a beveled edge. Handles may be fiberglass or wood. Vaughan’s exclusive hollow-core fiberglass handles provide great balance and more effective shock absorption than solid fiberglass handles. Two similar hammers include a machinist’s riveting and a tinner’s riveting. The machinist’s riveting hammer has a round head with a flat striking face and a rounded cross-pein on the opposite end of the head. The tinner’s features an octagon head with a flat striking face.

Hand Drilling Hammers

These heavy, short-handled hammers are designed to use with star drills, masonry nails, steel chisels and nail pullers. They provide lots of power and are available in sizes ranging up to 3 pounds.

Blacksmith’s and Double-Face Hammers

Blacksmith’s hammers feature a flat surface on one end of the head. The opposite end of the head features a wedge shape for working metal. They are available in sizes from 2 to 3 pounds. Double-face hammers feature a flat face on either end of the head and are used for a variety of metalworking purposes, including blacksmithing. They range in head weights from 2 to 4 pounds, and both styles come with wood or fiberglass handles. A similar shaped hammer is the lineman’s (farrier) or turning hammer.

Mauls

Last in the hammer lineup are mauls and sledges. Mauls and sledges come in sizes from 1-1/2 to 12 pounds and most feature wood handles, but fiberglass models are also available. Mauls and sledges are used for everything from driving stakes for concrete forms to other heavy-duty chores.

Mallets

Mallets, either wood or rawhide, are primarily used by wood carvers and those doing such chores as hand-cutting mortise and tenon joints, tapping joints together and other fine woodworking tasks. Dead blow hammers and rubber or hard plastic head hammers are also used for driving wooden pieces together for joining.

Driving Nails

Although having a variety of nail-driving hammers on hand may be appropriate for the professional builder or remodeler, three hammers will suffice for most chores. You’ll need a 16-ounce claw hammer for general purpose, a 20-ounce for framing and a 12-ounce for finish work. Hammers are like many other items, such as golf clubs. Even if you have a number of hammers to choose from, you’ll find one just seems to fit your hand and work-style better than others and over time becomes a “companion” you always pick up.

Using a hammer to drive nails is simple, it’s just not easy. Like any other skill, it takes practice, as well as proper technique. An old time carnie trick was to put your money down and see if you could drive a nail with one blow. A long-time carpenter, my dad could drive an 8d nail with a single blow. It’s too bad that trick doesn’t do us any good. However, driving nails properly is important not only to reduce fatigue and time on the job, but also for a good, solid and smooth construction. Bent nails don’t hold framing pieces properly and hammer tracks just don’t work on fine furniture. Last summer, while working with some kids on a church project, I taught one youngster the simple trick of “following” the nail when he began his first nail-driving chore. By the end of the day he was bending fewer nails and having a great time.

The first step is the proper grip. The hammer should be grasped near the rear of the handle to provide the most leverage. Some carpenter’s place the thumb on the top edge of the handle, providing not only more leverage, but better control. Place the nail in the desired position, place the hammer down on the nail head, holding it squarely in place, and give the nail a light tap to set it in place. Remove your fingers from the nail and drive the nail in place. It’s best to use several light-to-moderate blows, rather than trying to drive the nail with fewer blows. This allows the wood to separate better for easier nail penetration, and helps to prevent bending the nail. With the correct size hammer to match the nail size and chore, the hammer weight and swing will do most of the work, without having to create a strong down-force with your arm. The latter not only doesn’t allow for control, but is fatiguing, and over time can cause problems such as tendonitis, a common problem many old-timer carpenters suffer.

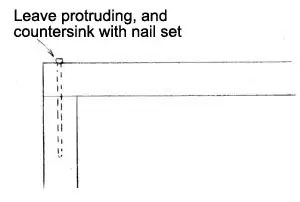

If driving nails in hardwoods, always predrill through the top board, or through the top and into the lower board, to a depth of about 2/3’s the nail length. Also if driving near the end of a board for finish work, even softwoods should be predrilled. For finish work, the nail should only be driven until the bulbous end of the nail is just above the wood surface. Then drive the nail slightly below the wood surface with a nail set. Nail sets come in different sizes. Choose a nail set that is slightly smaller than the nail head. On most finish work, nails should be driven about 6 inches apart.

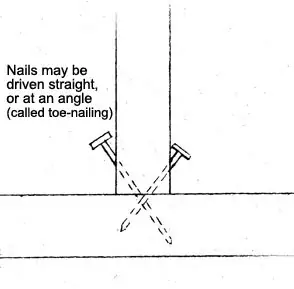

Nails may be surface nailed or edge nailed. Nails may be driven straight in, or many times in framing chores, at an angle called “toe-nailing.” In the latter technique, the starting piece must be blocked or held in place to prevent it shifting as the nail is started. For best holding power the piece should be toe-nailed on both sides. The claws on the back of the hammer are used to pull nails. Curved claws will work for smaller nails, but larger construction work requires the straight claws. Placing a block of wood under the hammer head can provide more leverage if needed.

One trick my dad used in his cabinet shop was to drill a hole in the end of his finishing hammer handle and melt a bit of beeswax into the hole. He then tipped a nail in the wax before driving in difficult woods.

Hammer Safety

The first rule of safety is to always use the hammer for what it’s intended. Do not use claw hammers, brick hammers or hatchets on hardened metal objects such as cold chisels, punches, star drills, drift pins, masonry nails, pry bars, nail pullers, hitch pins or clevises. Always use a hammer of the correct size for the chore, and make sure to strike the surface squarely. Do not create glancing blows. Do not strike a hammer or hatchet against another hatchet or hammer. And, the most important rule, always wear safety glasses or goggles when using hammers.

Nails

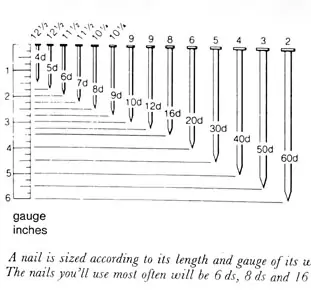

Nails are available in a wide variety of sizes and styles. They are measured by the “penny” (abbreviated “d”) and sold in bulk by the pound, or these days, simply in boxes off the rack. Nails are sized according to their length and the gauge of the wire they are created from. An eight penny (8d) nail is for example, 2-1/2 inches long, while a 10d nail is 3-inches long. The most commonly used nails are 6, 8, 10 and 16d.

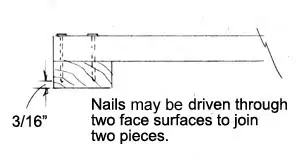

Choosing the proper nails is as important as choosing the proper hammer. The four most commonly used nails are multipurpose and include; common and box nails with flat heads, and casing and finish nails with narrow heads that can be sunk below the wood surface and concealed. Although the same general shape, common nails are thicker than box nails. Casing nails, although the same length as finish nails, are slightly thicker. The first step in choosing a nail is one that will hold without undue splitting, but length is also important. When surface nailing, the length of the nail should be 3/16-inch less than the total thickness of the combined pieces. When edge nailing, the nail length should be three times the thickness of the top or first piece of material.

A wide variety of specialty nails are also available, including drywall, roofing, underfloor, spiral-grooved, coated and so forth. Nails for use in exterior projects often have a special zinc coating and are called galvanized nails. These prevent corrosion from rust on siding and trim.