The Right Way to Fell a Tree with a Chainsaw.

Trees are an important part of the ecosystem but sometimes they need to be removed to prevent damage to surrounding areas. When it comes to felling a tree, the task is as much art as it is science. To exercise the proper amount of control to achieve the desired results without risking safety, the experts at Husqvarna offer the following basics on felling a tree.

Note that it is impossible to address all scenarios, circumstances and contingencies that can and will occur when felling, so this article is intended to give an understanding of basic principles.

Safety & Preparation

Before firing up the chainsaw, you must have a plan in place. The very first step is to read (or reread) the chainsaw’s Operator Manual and follow all instructions, precautions and warnings prior to using the saw. It is imperative to know the answer to the question “what needs to be done if an emergency occurs’’ and develop a plan for specific situations. This will help identify potential hazards beforehand and create an organized response if an emergency occurs.

An on-site first aid kit, cell phone programmed to the nearest emergency care facility, directions and distance to that facility and local utility contact numbers are a few basic components to a good emergency plan. And, whether in the back yard or the back 40, never work alone.

While it is mandatory for professionals, anyone using a chainsaw should include personal protective equipment (PPE) as part of their plan. A properly outfitted operator wears protective chaps or pants, eye and ear protection, appropriate footwear, work gloves and a helmet with visor. The proper equipment cannot eliminate the risk of injury completely but it can reduce the severity of an injury should an accident occur.

Before pulling the cord, it is important that users visually inspect the saw for any damage or leaks. Only use a chainsaw that’s been well maintained and is in proper working order. The chain’s cutting teeth need to be properly sharpened, and make sure the depth-gauge setting is correct.

Saw Operation

When using a chainsaw, understanding the three reactive forces of the saw—push, pull and kickback—will help prevent accidents.

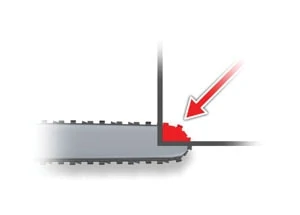

Never cut with the upper half of the tip of the bar. Kickback occurs when the tip of the bar comes in contact with an object or gets pinched during operation, causing the bar to “kick” up and back towards the operator, which can result in a loss of control and possible injury.

That is why balance and stance are important to safe operation. The boxer’s stance, left foot slightly forward and both knees bent, is recommended to help maintain control of the saw and minimize fatigue when reactive forces are experienced.

Felling Techniques

Directional felling is the process of putting a tree in a preferred area and not necessarily where it wants to go. A “felling hinge” is the hallmark of directional felling. It is safe, efficient and steers the tree as it falls to the ground.

When surveying the tree and surrounding area, identify potential hazards on the ground, in the tree and where the tree will fall. Clear leaves, limbs and live saplings or anything that will impede a clean and controlled cut or complicate the escape route. Look for dead limbs and hanging branches that could possibly fall when cutting or as the tree falls. Also, examine the path and area where the tree will fall for hazards such as potential hang-ups or stumps.

It is exceptionally rare to find a tree that does not lean.

The side lean will show which side is the “good” side and the “bad” side. The side the tree leans toward is considered the bad side of the tree. The lean will also help determine aim when placing the tree. If a tree leans three feet to the right, it is necessary to aim three feet to the left, to have the tree fall in the right location.

Trees with severe lean can be dangerous to fell because the tree can move in the leaning direction too quickly, splitting at the base and creating what is known as a “barber chair” break in the tree. In such a case, the split wood can fly upwards, striking the operator with terrific force.

The next step is to map out the escape route. This is always opposite the direction the tree will be falling and should be at a 45-degree angle from the tree. Remove any obstacles and make note of any potential hazards such as holes or tree stumps. When the tree begins its descent, don’t run or turn your back on it.

Sounds like a lot of work? Abraham Lincoln is credited with saying, “Give me six hours to chop down a tree and I will spend the first four sharpening the axe.” Preparation is central to success.

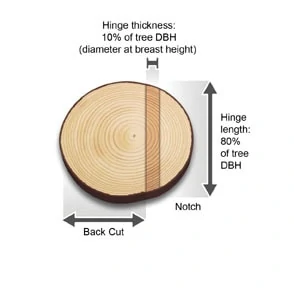

Next, the hinge will need to be determined. The hinge helps dictate how and where the tree will fall. Most industry experts will use a simple formula to calculate both the hinge length and thickness. To determine thickness, it is recommended to use 10% of the diameter of the tree at D.B.H (diameter at breast height) or 4-1/2 ft. from the ground.

A tree with a 20-in. diameter will have a 2-in. thick hinge. Hinge thickness is reduced for thicker trees and drier wood fiber.

The length is 80 percent of the tree’s diameter at D.B.H. So, for a 20-in. diameter tree, the hinge length is 16 in.

Historically, the 45-degree face notch dominated the industry, flat on the bottom and cutting at a 45-degree angle downward to create the opening. While this will bring the tree down, there is more risk with the reduced amount of control in placing the tree. The tree can only fall 45-degrees before the notch closes and the hinge breaks.

Today, most people recommend using an open-face notch, which is a 70-degree opening. This gives the cutter more control since the hinge will not be broken until the tree is almost to the ground. The open-face notch allows the back cut to be made level with the notch, whereas the 45-degree notch will need to be back-cut above the apex of the hinge.

To cut the notch, start with the top cut moving downward to the point of the hinge.

Many of today’s chainsaws will come with felling marks. Similar to the sight on a gun, these lines will help the operator align the cut with the direction the tree will be felled.

Next, make the bottom cut of the notch, being careful not to create a bypass by cutting too far into the tree and over-shooting the top cut (since this will weaken the hinge and reduce control). If you’re not sure of the progress while cutting, simply engage the chain brake and visually inspect the cut.

Once the notch is complete, you can perform the back cut. Two choices exist; the conventional back cut, where the cut is made from the back of the tree to the front where the notch is located, or the bore cut.

The bore-cut method involves plunging the saw directly through the tree and working forward and back to maintain hinge integrity and to create a back strap that helps hold the tree in place until it is time to drop it.

The back cut can be used with either the conventional 45-degree notch or the 70-degree open-face notch. When used in conjunction with the conventional notch, this method requires the cut to be above the apex of the notch to create a step. This will create some support for the hinge so not all of the force and weight of the tree is centered on the hinge.

With the open-face notch, the back cut can be performed at or near the notch line. By opening up the notch, more control is afforded, since the pressure on the hinge is more evenly dispersed across the face of the tree. The back cut begins at the rear of the tree and is brought forward towards the notch.

In both cases, it is necessary to cut until the notch begins to close and the hinge, if done properly, will start to control the tree as it falls.

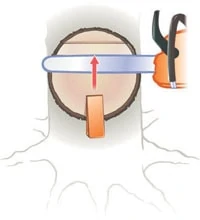

Felling wedges are extremely handy to help in preventing the chainsaw bar from becoming pinched in the back cut, particularly if the tree has some back lean. Lifting a tree 1 in. with a wedge at the back cut can move the top of a tree several feet. The amount that the tree top can be moved depends on the height and girth of the tree.

Notes on the Bore Cut

The bore cut is something that requires practice as it is an art form. Using the bottom edge of the bar, an initial cut will be made until the chain can bore or plunge into the tree. Never use the top, front area of the bar as this will result in severe kickback. Also, the bore cut should be made well behind the hinge so as to keep it safely intact.

Once entire tip of the bar and chain are in the tree, the saw can move back and forth to cut out the proper amount while still leaving enough of the back strap. When the tree is larger in diameter than the length of the chainsaw bar, bore cut no more than 50 percent through from the bad side of the tree and cut up to the hinge on that side. Then, bore cut the remainder of the way from the good side of the tree, slightly overlapping the first cut and out toward the back of the tree.

It is always preferred to finish cutting on the good side of the tree.

With the weight dispersed between the hinge and back strap, the final step is to cut the back strap, thus releasing the tree to fall. Activate the chain brake or turn off the saw and move away from the tree through the pre-established escape route.

Safety cannot be stressed enough. If, at any time, the circumstances become too intimidating, seek professional assistance.

Editor’s Note: Special thanks to the experts at Husqvarna for contributing this article. For more information on Husqvarna’s line of lawn, landscape and forestry products, visit www.husqvarna.com.

Before pulling the cord, inspect your chainsaw. Here are some core areas of maintenance that need to be addressed:

External – Look for cracks, leaks, loose hardware and modifications to the saw. Check the chain tension so that it does not sag from the underside of the bar, but can still be rotated by a gloved hand. Make sure the muffler is securely attached and check for a broken or worn starter cord. If any repairs are needed, do not use the chainsaw until it has been properly serviced by a professional service technician.

Fluids – Fill the gas tank with fresh correctly mixed fuel and the oil reservoir with chain oil. Fuel with an ethanol rating higher than E-10 should not be used.

Air – Check and clean the air filter regularly by blowing lightly inside to outside, brushing or tapping lightly, or soaking in water and mild detergent, rinsing and letting it dry for 24 hours.

Cooling System – Blow or brush the flywheel fins, cylinder head fins and air intake on the starter cover.

Safety Features – Check that the chain brake, throttle lock control and stop switch are working and free of damage. Confirm the chain catcher is in place and the anti-vibration system is working properly.

Bar, Chain, Sprockets – The chain’s cutting teeth need to be properly sharpened and depth gauge setting is correct. Inspect for visible cracks and wear in rivets and links. Remove the bar and check for a flat top rail. File away burred side rail edges of the bar which can create drag while cutting. Clean out the bar groove and the chain oil hole that allows movement of oil from the saw to the bar groove. Rotate the bar regularly for equal wear. Check that the bar tip sprocket turns freely and that the teeth are rounded and not pointed. Check the wear on the chain drive sprocket and replace it when replacing the chain.

Preventive maintenance will help ensure the chainsaw is in top operating condition to increase operator safety.