If you work long enough, you’ll discover you really can’t have too many drill bits. They’re needed for numerous around-the-home, shop and contractor chores. Bits are available for drilling just about any material, including wood, the various metals, concrete, stone, tile and even glass. As you can guess, a wide variety of “bits” or tools for drilling are available for use with portable drills and drill presses. These include standard twist drill bits, auger bits, spade bits, Forstner bits, expansion bits, step-drill bits, hole saws, pilot-hole and screw bits, and plug cutters.

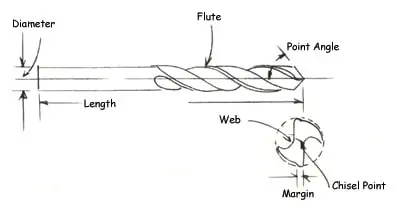

Twist drill bits are the most common, and are available in a variety of sizes, materials and shapes. Show is a typical bit configuration.

Twist Drill Bits

Twist drill bits are some of the most common shop tools. They’re available in a wide range of sizes, point and twist shapes, and these days they’re not only available in standard industrial-grade steel, but also in “exotic” materials including titanium coated, black oxide and cobalt. Don’t buy cheap bits. They’re frustrating and can be dangerous, causing you to push or exert force when drilling.

Drill bits are the most common tool accessory, a $740 million North American market. Drill bits are available in a wide variety of types, sizes and materials for specific metal- and wood-boring chores.

Drill bit sizes come in four categories: fractional sizes, wire-gauge sizes, letter sizes and metric. Fractional sizes begin at 1/64 inch and run to more than 4 inches. The smaller bits increase in size by 64’ths, the mid-size bits by 32’nds and the larger bits by 16’ths. Wire-gauge numbers run from No. 1 through 80 (the smallest). All sizes are less than 1/4 inch and begin at 0.0135 inch (No. 80) up to 0.2280 inch (No. 1). The numbers correspond to standard wire sizes. These bits are used where exact hole dimensions are required, such as when tapping threads in holes. Letter size bits begin the next size up from No. 1 wire gauge. They begin at 0.2340 inch (A) and run to 0.4062 inch (Z). The largest size is smaller than 7/16 inch. These too are used to make precise hole sizes.

And, of course, there are metric sizes in millimeters. One millimeter is equal to 0.0394 inch. Shown below is the Vermont American conversion chart to convert metric and decimal.

Twist bits are commonly sold in a standard length, called “jobber” lengths, with the length varying according to the bit diameter. These will handle most of the jobs you’ll tackle, but at times a longer length may be needed. In this case, extensions are available for 1/4-inch bit shanks. With many “hex-heads” available these days, an extension will fit most bit sizes, but they are designed primarily for woodworking, not metal chores.

The next step in twist drill “school” is the point angle. Typically, 118 degrees is the most common angle. But these drills require a starting “dimple” in metal with a center punch, otherwise the bit will “walk” or “skate” away from the hole location. Bits with a 135 degree point will start their own hole in metal and, of course, can be used on many other materials. Brad-point bits provide even more precise starting in both metal and wood. Woodcraft Supply carries extra-long, 10-inch brad-point bits, handy for many furniture construction chores.

The helix and flute angles are also important, and again these days there’s more variety to choose from, depending on the job. The new Bosch Speed Helix design has an aggressive flute structure engineered to remove material faster, and the 135-degree split point eliminates walking, making the bit more efficient, with up to three times faster penetration than bits designed with a standard helix. Quicker penetration also means less energy on the part of the drill turning the bit, as well as the user pressing down, which translates into more battery life for a cordless drill/driver and less fatigue on the part of the user.

Twist drill bits are made of a variety of materials, with carbon steel the softest. High speed steel (HSS) bits are also available. As mentioned earlier, exotic materials these days include black oxide, titanium and cobalt. Each is designed for a specific purpose, and Bosch has introduced new designs in these bits as well. The Bosch High-Speed Steel Black Oxide bits are all-purpose for heavy-duty drilling in wood, plastic, carbon and alloy steels, aluminum and soft cast iron.

Titanium is designed for repetitive heavy-duty drilling in wood, plastic, common stainless steels, carbon and alloy steels, and soft cast iron. The new Bosch titanium drill-bit line offers the industry’s toughest titanium bits. By coating each bit with high-speed steel-titanium nitride, Bosch not only made the surface of the bit harder, in excess of 80 HRC (Hardness Rockwell), but also dramatically reduced the amount of heat and friction created between the bit and the work piece. As a result, the bit will last up to six times longer than standard black oxide bits and drill through more materials.

Craftsman offers its Zirconium-coated bits also with a split point, as well as a groove design that breaks up chips.

Zirconium-coated bits, such as the Craftsman bit sets, are coated with Zirconium nitride for extra strength and feature a split-point and groove design that breaks up chips for faster penetration and more precise drilling. The point design eliminates walking.

Cobalt bits will drill extremely hard materials, including hardened stainless steel, cast iron and titanium, but can also be used for wood and plastics. The new Bosch cobalt drill bits feature a special alloy that allows the bits to heat up to 1,100-degrees F, allowing each to last in extremely abrasive materials that would normally destroy any other bit. Further advancing the efficiency, Bosch also increased the overall bit hardness up to 68 HRC, perfect for penetrating tough or abrasive materials. A 135-degree split point starts drilling on contact by eliminating walking. And finally, a thicker web design increases the overall rigidity to prevent the bit from snapping in hard materials.

Auger bits are longer than most other bits and are used for boring holes to run wiring or plumbing. (Photo courtesy of Vermont American)

Auger Bits

Auger bits solve the problem of boring deep holes and fairly large holes, such as through several studs to run wiring or plumbing. They are typically 7 inches in length and will cut through three 2-by-4’s. For even deeper holes, ship augers, with lengths of up to 17 inches, are available.

Spade bits are used where rapid drilling of tough materials is needed. The new Bosch RapidFeed spade bits have a patent-pending tip similar to the screw tip of an auger bit, plus an increased cutting angle.

Spade Bits

Another alternative to boring quick and large holes in studs and other projects is with spade bits. Sometimes called “paddle” bits because of their shape, these bits come in a variety of sizes and make quick work of boring rough-in holes. The new RapidFeed spade bits from Bosch have a patent-pending tip similar to a screw tip on an auger bit. The RapidFeed design helps pull the bit through the wood. This allows the bit to cut up to three times faster than other spade bits. An increased cutting angle accommodates the increased speed of cut. Specially engineered cutting spurs on each edge actually scribe the outer edge of the hole before the cutting edge removes the material, creating a cleaner hole.

The Vermont American WoodEater bits cut three times faster and last seven times longer than typical spade bits. (Photo courtesy of Vermont American)

An alternative to spade bits for boring these types of holes are the WoodEater bits from Vermont American. These bits will cut three times faster and last seven times longer than spade bits. The Milwaukee PathFinder bits are also great for these chores. They have a unique design with six different cutting edges, allowing it to cut forward, backward and on all sides. This makes precise, clean holes in wood, composites, chipboard, plasterboard and hard plastics.

Forstner bits, such as those shown from Woodcraft Supply, are used where precise holes are required.

Forstner Bits

Forstner bits are the best choice for boring precise holes in wood. These bits feature a precise diameter with a circular cutting edge protruding past a center cutting edge and a spur in the center to guide the bit. They are best used in drill presses for precise work, although they can be hand-held with less precision. They are not quite as fast a cutting bit as the spade and other fast-style bits. Woodcraft Supply offers a 16-bit boxed set in a wooden box. Individual bits are also available. Rockler offers carbide Forstner bits in extra lengths for boring deeper holes. They also have an exclusive drill jig guide that helps position the bit precisely in place.

Expansive bits have an adjustable “spur” that allows you to custom fit the bit to the hole desired. (Photo courtesy of Vermont American)

Expansive Bits

Expansive bits are wood-boring bits that can be adjusted to “infinite” hole sizes. They are available in several sizes, ranging from 5/8 to 1 3/4 inches and 7/8 to 3 inches. They are available with tapered shanks for use in hand-held brace-and-bit, or with hex shanks for use with power drills.

Step-drill bits allow drilling different size holes with one bit. The new IRWIN Unbit has a redesigned flute that reduces vibration and provides more precise round holes. (Photo courtesy of IRWIN)

Step-Drill Bits

Step-drill bits allow you to drill multiple sizes of holes with just one bit, by simply stopping the bit at the desired hole diameter. The new IRWIN Unibit with SpeedPoint Tip Geometry allows faster starts and penetrates six times faster than former bits. The flute design reduces vibration and provides more control for precise round holes in mild steel, copper, brass, aluminum, plastic, acrylic, wood and laminates. Unibit step drills are made of industrial grade high-speed steel. Laser marked sizes make it easy to identify hole sizes. Titanium nitride coating is available on several sizes to create less friction.

Pilot-hole bits allow you to drill pilot holes for screws in hardwoods to prevent splitting. They may also be used as countersink, or counterbore bits, depending on their style. The Stanley bit shown is made to match specific screw sizes.

Another type of pilot-hole bit allows you to adjust the bit length to match the screw length. The craftsman Speed-Lok system countersink/pilot-hole bits are available with a fast change chuck. Insert the chuck in the drill bit. Use the countersink bit to drill the hole, flip the holder, and you can drive the screw.

Pilot-Hole Bits

Pilot-hole bits allow you to drill screw holes and countersink or counterbore at the same time in wood. They are the choice when fastening wood pieces, especially hardwoods that may split out without pilot holes. Pilot-hole bits are available in several sizes to match standard screw sizes. Some are made as one piece and must be matched to screw lengths as well. Another version has an adjustable bit fitted into the bit body that can be adjusted to the screw length. Matching the pilot bits are plug cutters that can be used to cut plugs of wood to cover the screws.

Plug cutters are available to match counterbore bits for cutting matching or contrasting woods to cover screw heads.

Self-centering bits are used for installing cainet hinges.

(Photo courtesy of Woodcraft Supply)

Specialty Bits

Other specialty bits include the Vermont American glass and tile bits for smooth accurate drilling of ceramic tile, marble, china, mirrors and glass. The spear-pointed tip reduces breakout. Countersinks are bits designed to countersink screws. If you do a lot of cabinet work, installing numerous hinges, self-centering hinge drilling Vix bits, from Woodcraft Supply, make precise and quick work of drilling holes for hinge screws.

Hole saws are available in several different sizes to bore large holes such as when installing locks in doors.

Masonry bits are used for boring in concrete and other masonry. The Vermont American Tapcon screwhole bits are used for boring holes for masonry screws.

Although not actually drill-bits, hole saws use a drill bit to center a circular saw to cut large holes in wood, metal, plastics and other materials. Masonry bits are available in several styles for rotary hammer drills, or standard drills. Masonry bits with double flutes, such as from Vermont American, provide faster cleaning of materials. Also available from Vermont American, are Tapcon concrete screw bits for drilling pilot holes for 1/4-inch Tapcon concrete fasteners. Grizzly Industrial also carries a wide range of drill bits of all types, including the specialty bits.

The Bosch Clic-Change Quick Change Bit System is available in a wide variety of bits. (Photo courtesy of Bosch)

Quick-connector systems allow you to instantly change bits, drivers and other accessories. Show is a 120-piece Craftsman set.

(Photo courtesy of Craftsman)

Quick Connector Systems

One of the biggest changes in drill bits is the introduction of hex-shank bits. This makes it easier to lock the bit in a drill or drill press and prevents slipping. The second major advance is the creation of quick-connector systems that allow instant changing of bits, and other accessories, such as drivers. These are available in a number of different sets, and individually as well. The Craftsman Speed-Lok System comes in a 120-piece Master Drill and Driver set that includes a quick-connector, hex-shank twist bits, masonry bits, spade bits, pilot-hole bits, numerous drivers and other accessories. Rockler offers their Insty-Driver System of cabinetmaker bits with self-centering bits, tapered drill bits and countersinks. Bosch offers its Clic-Change Quick-Change Bit System in numerous twist, masonry and other bits, as well as drivers. DeWalt Rapid Load Quick Change sets also utilize a quick-change chuck.