Give your Carpentry an Edge

By Rob Robillard

Wouldn’t it be nice if we could apply thin layers of skin to cover our aged, wrinkled and rough edges? For a pretty penny I’m sure some plastic surgery could accomplish this, but nothing covers rough edges as nice as applied veneer banding.

I recently was asked to build AC-grade plywood cabinets for a client. To finish the cabinets I covered the outer sides with rustic, rough sawn boards and matching overlay doors. The insides of the cabinet show the A side of the AC plywood. The only surface that was not addressed was the rough plywood edges.

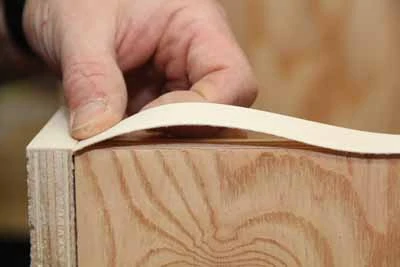

This article shows how I covered the plywood edges with veneer edge-banding tape.

What is Veneer Tape?

In cabinet making and woodworking, veneer refers to thin slices of wood, usually thinner than 1/8 in., that typically are glued onto the edges of core panels, doors, shelves, tops and panels for cabinets and furniture.

Veneer is obtained either by “peeling” the trunk of a tree or by slicing large rectangular blocks of wood known as flitches. The appearance of the grain and figure in wood comes from slicing through the growth rings of a tree and depends on the angle at which the wood is sliced.

There are three main types of veneer-making equipment used commercially:

Rotary lathes turn the wood using a sharp blade and peel off continuous veneer rolls. Rotary-cut veneer is mainly used for plywood.

Slicing machines operate in a fashion that raises and lowers the flitch or piece of log against a blade. The resulting slices of veneer look like sawn pieces of wood, cut across the growth rings. This is often referred to as “crown cut”..

Half-round lathes manipulate the logs in order to obtain the most desirable parts of the grain for the best looking veneer.

Veneering is an ancient art, dating back to the ancient Egyptians 4000 years ago who used veneers on their furniture and sarcophagi (the ornate coffins they were buried in). In Egypt, wood was

a scarce raw material, and the veneering process allowed the precious wood to be used more economically by maximizing the available supply.

Today’s Veneer

Veneer tape today can be purchased at a lumber yard and comes as a pre-sanded, ultra thin layer of wood or other material. This veneer tape can then be attached to the edge of plywood in order to make the plywood look like a solid piece of wood.

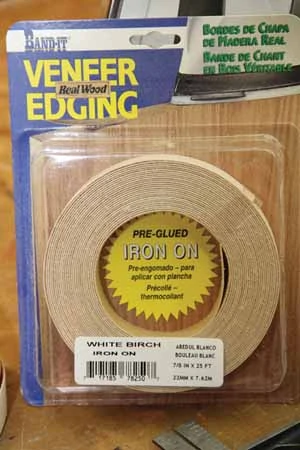

The veneer edge-banding tape we use has a heat-sensitive glue backing and applies quickly with an iron. Using veneer edge banding results in a clean and solid-wood look and is a fairly easy DIY project.

Real wood edge banding comes in several sizes and species of wood. The 7/8-in. edge banding is ideal for 3/4-in. thick plywood or veneered panels because it allows a bit of overhang, making it easy to trim flush with an edge-trimming tool. The tape is impregnated with hot-melt adhesive that creates a high-speed permanent bond once heated. The veneer is also pre-sanded and readily accepts stains and finishes.

Veneer edge tape is typically applied with an iron. I prefer to use furniture-grade birch tape that’s slightly oversized, like 25/32 or 13/16 inch. By installing a slightly oversized tape you can trim the edge banding to an exact fit.

Application of Veneer Edge Banding

1. To apply the veneer edge-banding tape, heat your iron to just shy of the hottest setting. Use care with placement of the iron while not using it.

2. Cut a section of tape 1-in. longer than needed.

3. Using a square and a utility knife, square off your starting edge.

4. Position the squared edge on the edge of your plywood or other substrate and smooth it with a few passes of an iron.

5. Heat only 6 inches at a time with the iron.

6. Use a roller or smooth block of wood to firmly press down the heated section of veneer tape. Roll it back and forth, working the glue into the plywood.

7. Repeat this process until you get within a few inches of the end of tape.

8. Use a square and utility knife to cut the end of the tape to fit

9. Iron and press the tape firmly.

10. Trim the excess width and length with a utility knife.

Tip: Apply your over-sized width tape flush to one side. This will eliminate the need to trim both sides of the edge after the tape is installed. If possible place the material upside-down on a workbench and trim the tape against a table. If access is difficult, as for a large bookcase, use a block of wood as a backer for your utility knife.

Applying Intersecting Veneer Tape

With built-in cabinetry and furniture you often have vertical and horizontal areas that need edge tape. I always install the long pieces first (usually vertical) and then work on the perpendicular edges. The procedure is similar to standard application, but with a few additional steps:

1. Cut a longer than needed strip.

2. Square up your starting end and butt it tightly to the pre-installed veneer edge tape.

3. Heat and press the tape into the joint. This ensures the edging will not slip away and create an unsightly open seam between the two pieces.

4. Heat and roll your tape until you get approximately 3 to 4 inches from the end.

5. Do not heat these last few inches yet.

6. Square and cut your end approximately 1/64 longer than the seam.

7. Bow up your tape and tuck your seam tight to the edge of the already installed veneer tape. Push the tape down. The additional length ensures a very tight fitting seam.

8. Iron and press the tape down to complete the glue installation.

9. Trim the tape to fit.

For both applications, finish up by sanding the edges of the tape with 150-grit abrasive. Slightly cant your sanding block to smooth the corners and give the panel the convincing look of solid, natural wood.

Editor’s Note: Robert Robillard is a remodeling contractor based in Concord, MA, and editor of a www.AConcordCarpenter.com.

Side Note 1

Grades of Plywood

Plywood is graded on quality and the appearance of the outer layers of veneer. An A grade indicates the plywood has the best appearance, all of its holes are patched, and it has a sanded finish. “C” grade plywood is un-sanded and may have both knots and defects visible on the board face. AC plywood has one A side and one C side.

Side Note 2

Types of Veneer Treatments

Veneer tape is one of several ways to cover exposed edges of plywood. These photos show how we cut 1/4-in. rigid strips of oak, mitered at the corners, to conceal the plywood edge of a shelf. There are several approaches to edge treatment, all with different results and applications.

• Solid edge banding, like the thin strips shown.

• Solid edge banding made of thicker wood strips that can be routed for a decorative profile.

• Oversized edge-banding or nosing that creates an overhang.

• Solid joinery.

Side Note 3

Wood-Glide can be used on all moving parts that would normally require a lubricant, eliminating the need for several different products in the work area. This all-purpose lubricant can save a tremendous amount of money by replacing most other lubricants that contain chemicals such as Teflon or silicone, which are extremely harmful to the finishing of wood. Wood-Glide can be used on all wood, metal and plastic applications without any adverse side effects. As a glue-releasing agent, the product will prevent adhesion of excess glue, while not interfering with the glue-to-glue bonding. Par Enterprises offers a 100-percent money back guarantee to anyone who is not satisfied with the product. Visit woodglide.com.